Egg tray making machine | paper egg tray Equipment

The egg tray making machine, paper pulp molding machine(production line) is used to produce all kinds of egg trays. Egg trays are visible in our lives with many forms and functions. And it also can make your own egg cartons. Because of its simple production process, low cost and no environmental pollution, it is called the “green” industry. And we also help you make manufacturing business plan.

Introduction of egg tray making machine

Egg tray machine is a general name for the pulp egg tray machine, paper pulp molding machine used to manufacture eggs for long-distance transportation. It mainly consists of machinery such as forming machine, hydraulic pulper, vacuum dehydrator, air compressor and drying box. You may need to have a great manufacturing business plan, our professional with rich experience will help you.

The raw material of the paper egg tray machine is waste paper. The polished pulp is transported to the egg tray making machine through the pipeline, and different styles of egg trays can be manufactured through different molds on the main machine, and the molds can also be replaced to produce industrial packaging such as apple trays, wine trays, and seedling trays. After the successful shaping, the basic shape of the egg tray comes out, and then after drying them, you get the egg tray.

Paper egg tray machine Video

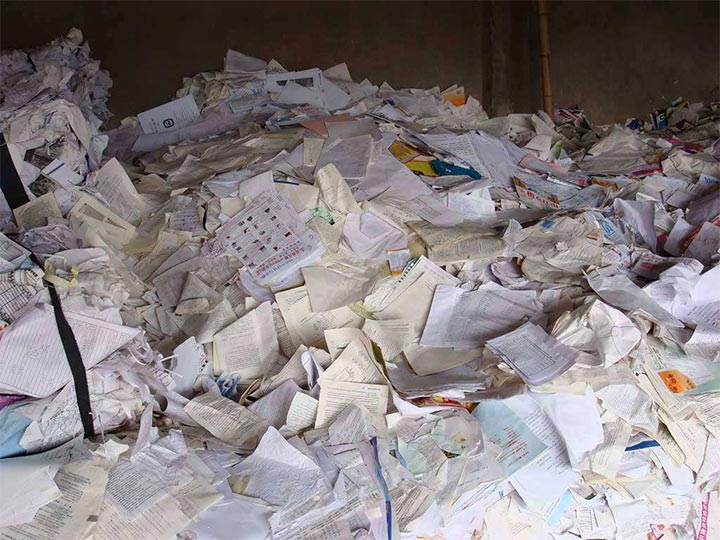

Raw materials of paper egg tray machine

The whole manufacturing process of the egg tray making machine is very environmentally friendly, starting from the main raw materials used to the egg tray molding. Molded egg trays, molded egg cartons, molded fruit trays and other tray products are made of waste newspaper, waste carton paper, waste printed matter, and various paper product factory trimmings as raw materials, which are hydrolyzed, filtered, and water injected into a concentrated pulp, which is the raw material for the egg tray machine.

The production process of the egg tray machine

1. Pulping equipment

Paper pulping is an essential part of the egg tray production line. It can process all kinds of waste paper, such as newspapers, waste books, cartons, etc. These waste papers are pulverized and pulped to obtain pulp. The main equipment of the pulping equipment: hydra pulper, vibration screen, consistency, controller, thrusher pulp and control box. It can add pressure screen refiner and other parts according to customer’s requirements.

2. Egg tray forming equipment

The egg tray making machine will finish the most important forming step. The pulp is formed on a forming part through the vacuum function. Then we get the wet egg tray. The transfer mold transfers the egg tray to the conveyor belt or small cart Then delivers the egg tray to the dryer line or use natural drying.

3. Egg tray drying equipment

When the egg tray is forming, it contains a lot of water. So the product needs to be dried, which is easy to store. There are mainly three drying methods: natural dry, brick drying, and metal dryer liner. Choose the appropriate drying method according to the capacity. You can choose natural drying if the capacity is below 1500pcs per hour. Metal dryer line: This drying method can use coal electricity or gas as fuel.

Then pulping products can be dry in recycled hot air. The drying temperature can be 180-220 ℃. Then use an axial fan to absorb the water quickly. Our dryer line includes a single belt layer and a multi-belt layer, a single dryer line. The single dryer line length is 42-45 meters. The double-layer length is 22-25 meters. The multi-layer can save the workshop area and use heat more efficiently.

4. Egg tray packing equipment

The pulping mold product through forming and dry then can be packed to storage. This egg tray packing machine is used to make the product more flat and smooth. Its temperature usually is 120-200℃.

Parameters of Egg tray making machine

| Model | SL-3*1 | SL-3*4 | SL-4*4 | SL-4*8 | SL-5*8 | SL-5*12 | SL-6*12 | |

| Capacity(pcs) | 1500 | 2500 | 3500 | 4000 | 5000 | 6000 | 8000 | |

| Paper consumption(kg/h) | 120 | 200 | 280 | 320 | 400 | 480 | 640 | |

| Water consumption(kg/h) | 300 | 450 | 560 | 600 | 750 | 900 | 1040 | |

| ElectricityConsumption(kw/h) | 32 | 58 | 78 | 80 | 85 | 90 | 100 | |

| Worker | 3-4 | 4-5 | 4-5 | 5-6 | 3-4 | 3-4 | 3-4 | |

| Single layer drying tunnel consumables | Coal(g/h) | 73 | 109 | 150 | 170 | 192 | 218 | 300 |

| Diesel(kg/h) | 28 | 42 | 48 | 60 | 70 | 84 | 115 | |

| Natural gas(m³/h) | 25 | 37 | 51 | 58 | 63 | 75 | 103 | |

| Liquefied gas electricity(kw/h) | 331 | 495 | 563 | 680 | 826 | 990 | 1360 | |

| Workshop floor space(㎡) | 45 | 80 | 100 | 100 | 140 | 180 | 250 | |

| Dryer floor space(㎡) | 216 | 216 | 216 | 238 | 260 | 300 | ||

How to judge the quality of egg tray machine products?

The forming quality of the paper egg tray machine is good, poor, or very poor, which is classified by the degree of homogeneity of the egg tray or the uniformity of fiber distribution. It requires that the fiber concentration is the same microscopically in a certain area selected at random on the egg tray.

The closer the fiber distribution is to this ideal state, the more homogeneous it is. Therefore, the quality of the egg tray making machine pulping system is important. The storage of pulp, flow feeding and the performance of the egg tray equipment forming machine all affect the fiber distribution in the paper mold product to some extent.

Final products of egg tray making machine

The following paper trays are taken by our sales managers from our factory. The final products of the egg tray machines are not only paper egg trays, but also egg boxes, shoes stand, paper bowls and so on. It can produce many different shapes according to its molds.

Related egg tray product of egg tray making machine

1. Egg tray

The paper egg tray has better gas permeability, fresh-keeping property, and excellent cushioning and positioning function, especially suitable for large-scale transportation and packaging of eggs, duck eggs, goose eggs, and other eggs.

2. Fruit egg tray

The pulp can be made into a paper tray with a fruit-curved structure for the packaging of peaches, pears, citrus, apples, pineapples, tomatoes, etc., especially for exporting fruit. It can avoid collision damage between fruit.

3. Electrical gasket tray

The paper mold material is used as a gasket, which has the advantages of good plasticity and strong good protective effect. It fully meets the internal packaging requirements of electrical products. Its production process will not pollute the environment.

4. Fragile protective gasket

The paper tray is easy to make. It is convenient for packaging and has a shock cushioning capability. Moreover, the raw materials of the products are easy to purchase, the production cost is easy to control, and it is suitable for large-scale production and application.

5. Food (medicine) packaging

Many food and medicine can be packed by the paper tray. It is not only clean and easy to use but also recyclable, which meets environmental protection and human health requirements.

6. Special industrial paper tray packaging

Some products require great care in packaging, storage, and transportation. They cannot collide, with static electricity, moisture, or rust during transportation. The paper material can solve these problems very well.

Zhengzhou Shuliy Machinery has sold the paper egg tray machine to Nigeria, Morocco, and other countries. The whole production line is easy to learn. The instruction manual is provided with the egg tray making machine. There are semi-automatic production lines or fully automatic production lines. Egg tray making machine price is reasonable in the market. We can produce a shoe tray, fruit tray, apple tray, wine tray and so on. We will supply a professional sales consultant to solve your problems if you need this machine. Welcome to contact us!

Features of paper egg tray and Egg Tray Machine

Products produced by the egg tray making machine are produced from waste paper. The material is very simple, but paper egg tray machines are very practical to use and have their own characteristics, such as waste paper is much easier to collect than plastic, their cost is lower, the paper trays are applicable to recycling, and so on.