Egg carton making machine | Fruit tray forming machine

The egg carton making machine is the most important machine in the egg tray production line. This machine adopts the principle of hot press forming. The paper pulp transformed into fiber suspension is evenly coated on the surface of the mold, and then it is pressed to form the egg tray. The egg carton making machine can be divided into single-sided egg tray machines and multi-sided egg tray machine. The multi-sided egg carrier can also be divided into the 4-sided egg carton making machine, the 8-sided egg tray machine, and the 12-sided egg tray machine.

The structure of the fruit tray making machine:

The fruit tray making machine is mainly composed of the drum type molding motor, forming mold plate, transfer mold plate, vacuum pump, air compressor, storage tank, fuselage, and some other parts.

How does the egg carton making machine work?

- Put the raw material into the pulper, add an appropriate amount of water, and make a fiber suspension after a long time of stirring.

- The water pump will suck the adjusted pulp into the water storage tank of the fruit tray forming machine.

- The pulp is adsorbed onto the forming mold by a vacuum system, and excess water slurry is transferred back to the storage tank via the vacuum adsorption system for reuse.

- Under the action of the air compressor, the molding die and the transfer mold are combined to press the pulp into the egg carton.

- The pressed egg tray will be sent out by the transfer mold to enter the next drying process.

Application market of egg carton machine:

The final product of the egg carton making machine is mainly related to the mold, and different products can be produced by replacing different molds. At present, this machine is mainly used in the production of egg trays, wine trays, apple trays, toy mold holders, electronic component packaging and so on. It has good shock-proof and buffer function, and can avoid collision during transportation.

Brief introduction of egg carton making machine:

Model introduction of the egg carton machine (taking SL-5 * 8 as an example):

SL: Abbreviation of our company name

5: Number of dies on the die plate

8: 8 mold plates

Single-sided egg carton forming machine:

Introduction:

The single-sided egg tray machine is also called a single-sided fruit carton forming machine, and the output is about 1000-2000 per hour. This machine has only one forming die plate, so it is also called a flap-type egg carton making machine. This model is currently one of the most popular models and is ideal for small and medium investors and novices.

Parameters:

| Model | Capacity | Water paper | Water consumption | Electricity consumption | Worker |

| SL-3*1 | 1000-1500pcs/h | 120kg/h | 300kg/h | 32kw/h | 3-4 |

| SL-4*1 | 1500-2000PCS/h | 160kg/h | 380kg/h | 45kw/h | 3-4 |

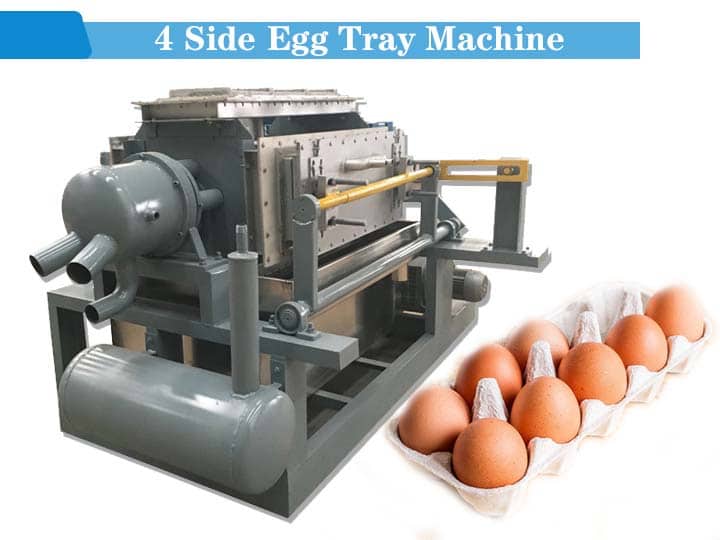

4-sided fruit tray making machine:

Introduction:

The four-sided egg tray forming machine is mainly composed of four mold plates with an angle of 90 degrees. Form a rotating cube. Due to the machine’s rotatable production, it saves waiting time and increases work efficiency. The machine can produce 2000-3500 egg trays per hour.

Parameters:

| Model | Capacity | Water paper | Water consumption | Electricity consumption | Worker |

| SL-3*4 | 2000-2500pcs/h | 200kg/h | 450kg/h | 58kw/h | 4-5 |

| SL-4*4 | 3000-3500pcs/h | 280kg/h | 560kg/h | 78kw/h | 4-5 |

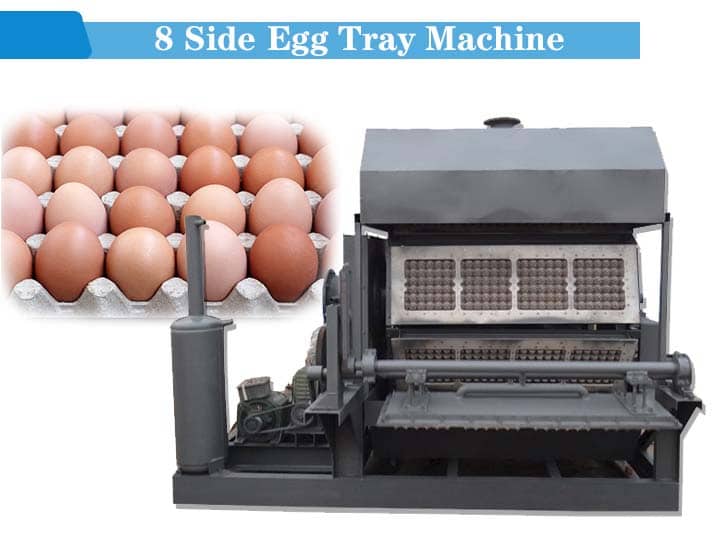

8-sided egg tray making machine:

Introduction:

This egg carton making machine has eight mold plates with an angle of 45 degrees for continuous operation. The machine’s transfer arm can perform 90-degree reciprocating work with high efficiency. This machine is a large-volume machine. The output can reach 4000-5000 egg trays per hour.

Parameters:

| Model | Capacity | Water paper | Water consumption | Electricity consumption | Worker |

| SL-4*8 | 4000pcs/h | 320kg/h | 600kg/h | 80kw/h | 5-6 |

| SL-5*8 | 5000pcs/h | 400kg/h | 750kg/h | 85kw/h | 3-4 |

12-sided fruit carton making machine

Introduction:

The productivity of the fruit tray making machine is currently the highest. There are 12 mold plates that are constantly rotating to make egg trays.

Parameters:

| Model | Capacity | Water paper | Water consumption | Electricity consumption | Worker |

| SL-5*12 | 6000pcs/h | 480kg/h | 900kg/h | 90kw/h | 3-4 |

| SL-6*12 | 8000pcs/h | 640kg/h | 1040kg/h | 100kw/h | 3-4 |

Why choose Shuliy fruit carton forming machine?

- Save labor costs. Mechanized production instead of manual labor can save a lot of labor costs.

- Wide application and simple mold replacement. Different products can be produced by simply changing the mold, which can be widely used in the packaging of fruits, alcohol, medical equipment, electronic components and the like.

- Well-made. The gap between the molds can affect the tightness of the final product. The egg carton making machine is equipped with stainless steel, the gap between the molds does not exceed 2mm.

- Environmentally friendly. The raw material is waste paper, and the water in the production process can be recycled, so almost no waste-water is generated and no burden is placed on the environment.

- Good pre-sales and after-sales service, the long warranty period of the fruit tray making machine.