Egg tray manufacturing process

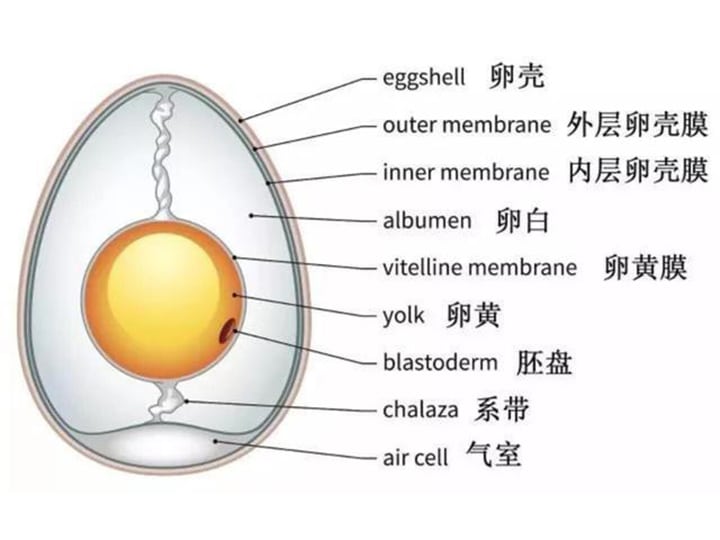

The whole eggshell is oval, one end is big and the other end is small. The main component is calcium carbonate, which accounts for 11.1% ~ 11.5% of the whole egg volume. The eggshell can be divided into the upper shell membrane, lower shell skin, and air chamber. After the eggshell is soaked in vinegar or some acid solution for a period of time, the eggshell will disappear and become a shell-free egg with only one layer of film left.

The shell membrane is a fibrous membrane wrapped in protein, which is an organic fibrous network composed of tough keratin. The shell membrane is divided into two layers: the shell membrane is thick, clinging to the eggshell, which is an opaque and unstructured membrane, and its function is to avoid the evaporation of moisture in the egg content; the inner shell membrane is about 1 / 3 of the thickness of the former, which is attached to the inner layer of the shell membrane, through which air can pass. The inner shell membrane and the outer shell membrane are most closely connected, and only at the blunt end of the egg are separated to form an air chamber. The air chamber is formed after the egg is produced. It is the contraction caused by the temperature difference between the inside and outside of the body and the formation of a gap between the shell and the membrane. If the water in the egg is lost, the air chamber will continue to increase. When the fertilized egg is hatched, it will increase with the development of the embryo.

The production process of the egg tray is complex. After the egg tray is processed and formed, it can not be used directly, because there will be a lot of water (about 75%), which must be evaporated in the drying equipment. This is the drying system in the egg tray production line.

At present, the hot air drying method is widely used in the domestic pulp molding products, and the hot air medium is used to dry the pulp molding products in the specific drying equipment. Hot air is mainly obtained by two methods: one is to produce hot air directly by burning in hot blast furnace; the other is to generate hot air by heat exchange between steam and air through the heat exchanger. The drying process of pulp molding products mainly consists of drying oven, mesh belt dryer and brick house.

No matter which drying equipment is selected, its drying principle is basically the same. At present, in order to save the cost of drying, many domestic manufacturers choose the method of natural drying and sun-drying to remove the moisture in the wet paper mold, but this method has low working efficiency, large commodity deformation, high damage rate and is restricted by the climate and site conditions.

This information is provided by Zhengzhou Shuliy mechanical equipment Co., Ltd., the manufacturer of egg carrier.