Pulp Bedpan Production Line

| Production capacity | 1,000–7,000 pieces/hour |

| Bedpan load capacity | 1–1.5 kg of waste |

| Liquid holding time | 4–6 hours, no leakage or deformation |

| Vacuum pressure | –0.04 to –0.06 MPa |

| Hot pressing temperature | 180–250 °C |

| Drying method | Hot air circulation or metal drying line |

| Power supply | Customizable |

| Mold types | Bedpan, urinal, care tray, custom shapes available |

You can now ask our project managers for technical details

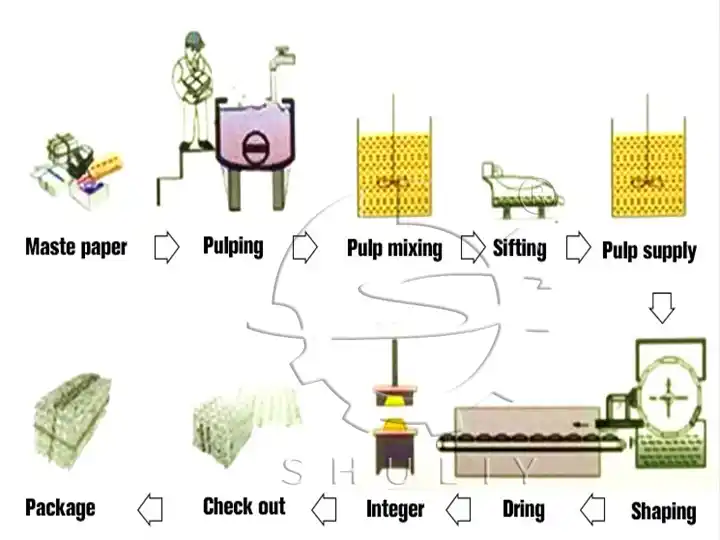

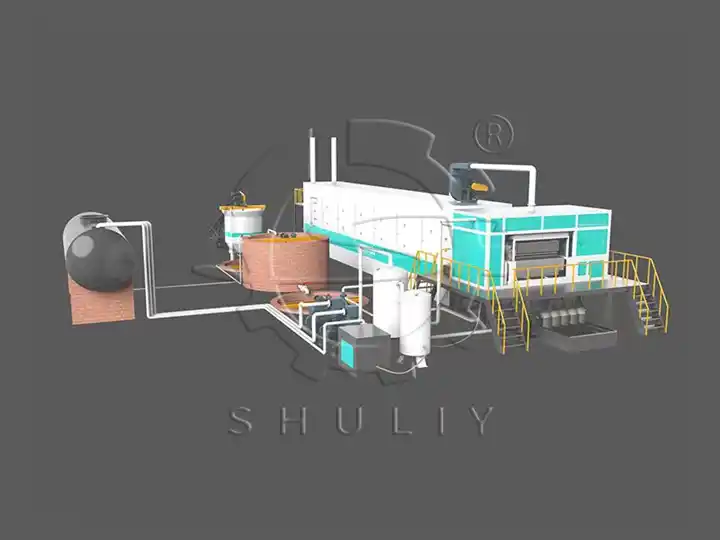

The disposable pulp bedpan production line is a fully automatic system. It uses recycled fibers such as waste paper and paper scraps. The process includes pulping, forming, drying, and hot pressing to make eco-friendly disposable bedpans (Pulp Bedpan, Pulp Urinal).

Bedpans can hold 1–1.5 kg of waste and contain liquid for 4–6 hours without leaking or deforming. They are low-cost, hygienic, environmentally friendly, and can be reused or recycled.

This large-scale production line can produce up to 7,000 pieces per hour, suitable for large enterprises. Various molds are available, and custom molds can be made based on your size and shape requirements. For more information, contact Shuliy Company for a production plan.

Components of the Production Line

Pulping System

Waste paper, paper scraps, or wood pulp sheets are put into a hydraulic pulper. They are stirred, pulped, and screened to make a pulp slurry with 0.8–1.2% concentration.

Vacuum forming technology shapes the pulp into bedpans, urinals, or care trays. The suction time and thickness are automatically controlled to ensure uniform structure and proper strength.

Drying System

Wet molds are quickly dried by hot air circulation or metal drying lines. The system is efficient and energy-saving.

Dried products are hot-pressed to smooth the surface, ensure accurate size, and improve appearance and strength.

Automatic Stacking System

Products are automatically counted, stacked, and packaged for easy transport and storage.

Working Principle

The paper bedpan production line uses pulp molding technology. Waste paper or plant fibers are made into uniform pulp. Pulp is vacuum-formed on special molds, then dried with hot air and hot-pressed at high temperature. This creates stable, strong, eco-friendly, and biodegradable disposable bedpans.

The process includes pulping, forming, drying, and hot pressing. Vacuum suction and heat ensure fibers deposit evenly, dewater, and dry into a final product.

Two Core Principles

Vacuum Forming

Vacuum removes water from the pulp. Fibers are evenly deposited on the mold surface, forming a wet bedpan. The mold usually has a pulp-suction part and a transfer part.

Key Points:

- Vacuum pressure: –0.04 to –0.06 MPa, pulls fibers onto the mold

- Fine holes in the mold: ensure even fiber distribution and consistent thickness

Hot Air Drying

High-temperature pressing makes dried pulp flat, compact, smooth, and stronger, improving water resistance.

Key Points:

- Hot pressing temperature: 180–250 °C

- Pressure and time: adjusted according to product thickness

Main Technical Parameters

| Parameter | Specification |

|---|---|

| Production capacity | 1,000–7,000 pieces/hour |

| Bedpan load capacity | 1–1.5 kg of waste |

| Liquid holding time | 4–6 hours, no leakage or deformation |

| Pulp concentration | 0.8–1.2% |

| Vacuum pressure | –0.04 to –0.06 MPa |

| Hot pressing temperature | 180–250 °C |

| Product thickness | Adjustable according to mold and product type |

| Automation level | Fully automatic (optional semi-automatic) |

| Power supply | Customizable depending on local standards |

| Drying method | Hot air circulation or metal drying line |

| Mold types | Bedpan, urinal, care tray, custom shapes available |

Molding Machine Technical Parameters

| Model | Capacity | Power | Voltage | Weight | Pulp Usage | Water Usage | Size(mm) |

| SL-1000-3X1 | 1000pcs/h | 38kw | 380V,50HZ | 2500kg | 80kg/h | 160kg/h | 2600*2200*1900 |

| SL-1500-4X1 | 1500pcs/h | 38kw | 380V,50HZ | 3000kg | 120kg/h | 240kg/h | 2800*2200*1900 |

| SL-2500-3X4 | 2500pcs/h | 55kw | 380V,50HZ | 4000kg | 200kg/h | 400kg/h | 2900*1800*1800 |

| SL-3000-4X4 | 3000pcs/h | 60kw | 380V,50HZ | 4800kg | 240kg/h | 480kg/h | 3250*1800*1800 |

| SL-4000-4X8 | 4000pcs/h | 95kw | 380V,50HZ | 7000kg | 320kg/h | 640kg/h | 3250*2300*2500 |

| SL-5000-5X8 | 5000pcs/h | 95kw | 380V,50HZ | 8000kg | 400kg/h | 800kg/h | 3700*2300*2500 |

| SL-7000-6X8 | 7000pcs/h | 120kw | 380V,50HZ | 10000kg | 480kg/h | 960kg/h | 3200*2300*2500 |

Product Advantages

Eco-friendly & Biodegradable

Made from waste paper or plant fibers, 100% biodegradable. Can be incinerated or naturally decomposed, with no plastic pollution.

Hygienic & Safe

Disposable use prevents cross-infection, ideal for hospitals, nursing homes, and other hygiene-sensitive places.

Lightweight & Practical

Reasonable structure, lightweight, strong load-bearing, easy to use for patients and people with limited mobility.

Heat-insulated & Leak-proof

Hot-pressed surface is smooth and dense, providing excellent leak resistance and shape stability.

Low Production Cost

Widely available raw materials, high automation, high efficiency, low labor requirement, and overall cost-effectiveness.

Highly Customizable

Molds can be customized in size, shape, and thickness to meet various medical and care needs.

Types of Pulp Bedpan Production Lines

Based on automation level, production lines are mainly: Fully Automatic and Semi-Automatic.

Semi-Automatic Pulp Bedpan Production Line

Workflow

Pulping → Forming → Wet bedpan manually transferred → Drying → Hot pressing → Trimming → Packaging

Drying options: Brick kiln dryer or metal mesh belt dryer

Fully Automatic Pulp Bedpan Production Line

Workflow

Pulping → Forming → Automatic demolding → Drying → Hot pressing → Trimming → Automatic stacking & packaging

The entire process requires no manual handling. The line is controlled by a PLC system; operators only need to set parameters on the control panel.

How to Choose Between Semi-Automatic and Fully Automatic Production Lines

Production Capacity Guide

- 1,000–2,000 pieces/hour: Consider a high-end semi-automatic line. Suitable if labor cost is low and the initial investment is limited.

- 2,000–7,000 pieces/hour: A fully automatic line is recommended. Semi-automatic lines may not run stably or efficiently at this capacity.

Investment & Cost

Semi-Automatic Line

- Investment: Low equipment cost, but requires more manual operation.

- Production limit: Lower capacity, may be inefficient for long-term operation.

- Stability & management: Relies on workers; product consistency is slightly lower.

- Suitable for: Small or startup businesses, low production volume, limited budget.

Fully Automatic Line

- Investment: Higher equipment cost, but highly automated.

- Efficiency: Saves labor, suitable for high-volume and continuous production.

- Stability & management: Continuous process; consistent thickness, drying, and forming.

- Suitable for: Medium to large enterprises, production above 2,000 pieces/hour, requiring efficiency and stability.

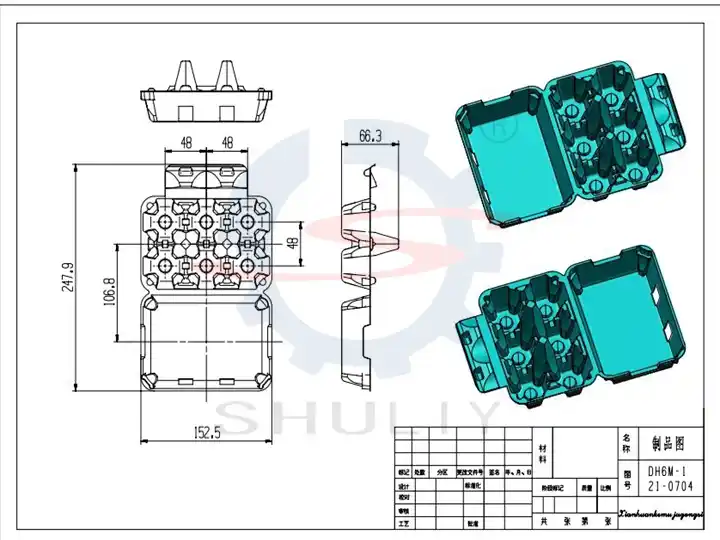

How to Customize Disposable Bedpan Molds?

Determine Product Specifications & Shape

- Dimensions: Provide length, width, height, and capacity.

- Thickness & Load Capacity: Decide based on pulp concentration and forming method to ensure safe use.

- Shape Design: Common shapes include bedpans, urinals, and care trays. Can be ergonomically designed for easy use and cleaning.

Choose Mold Material

- Aluminum Alloy: Fast heat transfer, durable, lightweight, suitable for small to medium batch customization

- Steel: High strength, long lifespan, ideal for large-scale production and long-term use.

- Surface Treatment: Electroplating or fluorine coating for easy demolding, anti-stick, and extended mold life.

Determine Mold Structure

- Single Cavity Mold: Forms one bedpan at a time, simple structure, low cost.

- Multi-Cavity Mold: Forms multiple bedpans at once, increases output, suitable for fully automatic lines.

- Replaceable Cores: Allows for different product sizes, increasing flexibility.

Mold Design & Manufacturing

- Design Drawing: Create a CAD model based on product size, shape, and forming process.

- Machining: Use CNC or precision milling to ensure dimensional accuracy and a smooth surface.

- Trial & Adjustment: Test on production line to check demolding, forming quality, and product size; fine-tune if needed.

Why Choose Shuliy?

- Advanced Technology: Uses hot-press forming technology for efficient and stable production of various bedpan sizes and shapes.

- Experience & Recognition: Over 10 years of R&D experience, supported by government and hospitals.

- Comprehensive Overseas Support: Includes installation, full video tutorials, and technical support.

- Certifications: TUV, SGS, CE, ISO9001

- Warranty: 12 months

- Customization: Power supply, voltage, plugs, and molds can be customized.

- Multi-Product Capability: Can also produce related products like emesis basins, patient bedpans, and urinals.