1000-1500 PCs/hr Small Egg Tray Machine

| Model | SL-3*1, SL-4*1 |

| Capacity | 1000-1500pcs/h |

| Water consumption | 300kg/h-380kg/h |

| Paper consumption | 120-160kg/h |

| Electricity consumption | 32kw/h-45kw/h |

| Worker qty | 3-4 |

| Warranty | 12 months |

You can now ask our project managers for technical details

The small egg tray machine, also called a single-sided egg tray machine, mainly uses waste paper, cardboard, old books, and other fiber materials. It produces various egg trays, such as 30-hole and 20-hole trays, with an output of 1,000–1,500 pieces per hour through pulp molding.

This small egg tray machine is perfect for small farms, family farms, and startup packaging businesses. It has low output, low investment, low energy consumption, and is easy to operate. With a fast return on investment, it is the first choice for many users and is popular in over 50 countries, including Nigeria, Brazil, Cuba, Colombia, Russia, Saudi Arabia, Morocco, Ghana, and South Africa.

Shuliy’s best-selling small egg tray making machines are the SL-3*1 and SL-4*1. Below, I will introduce these two models in detail.

Why is this small egg tray machine also called a single-side egg tray machine?

This small egg tray machine is called a single-side machine because it has only one forming mold and one transfer mold. All the wet egg trays are absorbed, formed, and demolded on the same side.

Compared with multi-sided machines (such as four-sided, eight-sided, or twelve-sided machines), single-sided machines have a simpler structure, take up less space, and use less energy. This makes them ideal for small-scale production and startup businesses.

Because it uses a single-sided forming method, each production cycle has a moderate output, operation is more straightforward, and maintenance is easier. This is why it is very popular in small factories and home workshops.

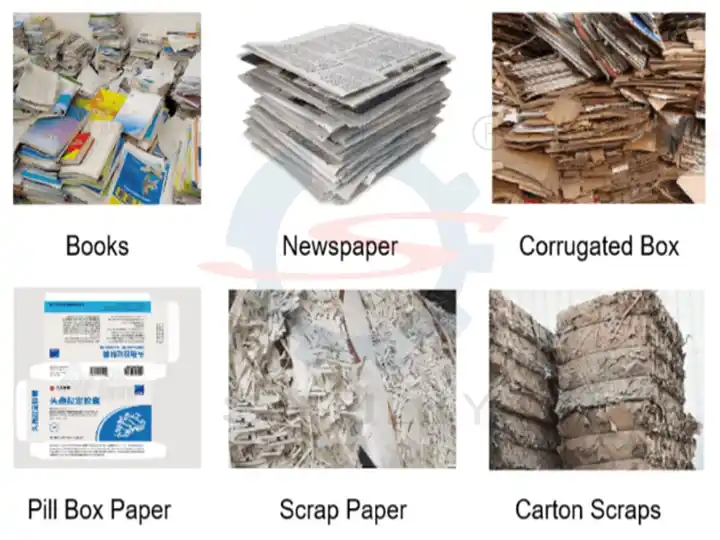

Raw Materials for Egg Tray Production

The small egg tray machine mainly uses fiber materials such as waste newspaper, kraft paper, corrugated paper, and cardboard. The production process is mainly physical, involving pulping, molding, and drying to make the egg trays.

According to customer needs, waterproofing or strengthening agents can be added to the pulp to improve the trays’ moisture resistance and durability. These additives remain in the product after drying without causing chemical reactions, discoloration, or odor.

Because of this, both the raw materials and the production process are environmentally friendly. The egg trays are fully biodegradable and do not cause secondary pollution, aligning with the current trend of green packaging.

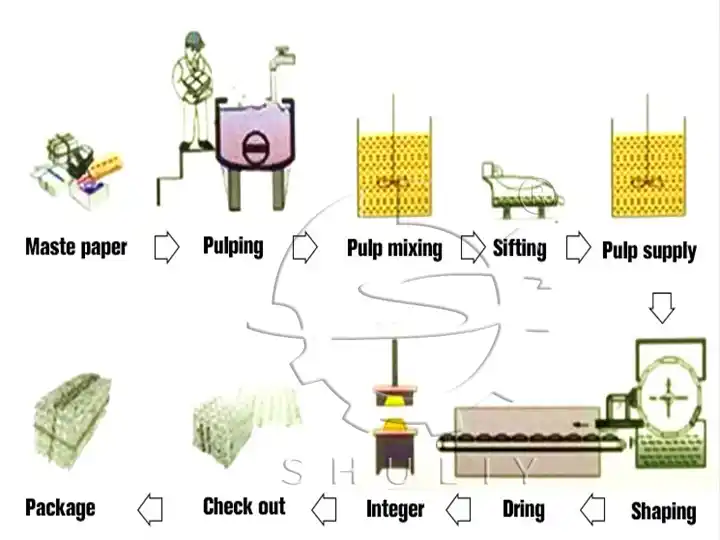

Working Principle of the Small Pulp Molding Egg Tray Machine

The small pulp molding egg tray machine works mainly through four steps: pulping, molding, demolding, and drying. First, waste paper, corrugated paper, and other raw materials are mixed with water in the right ratio to make a uniform pulp. Stirring and beating ensure the fibers are fully dispersed.

Next, the pulp is delivered to a single-sided forming mold. Under vacuum suction, the pulp evenly attaches to the mold surface, quickly forming a wet egg tray. The wet tray is then demolded and sent to the drying system (air drying or drying room) to remove moisture, producing strong, flat, and uniform egg trays.

The whole process is physical, without harmful chemicals, making it environmentally friendly and efficient. Each cycle can produce multiple trays at once, with low water and paper consumption, making it ideal for small-scale, high-efficiency production.

Types of Small Egg Tray Making Machines

Type 1: SL-3*1

The SL-3×1 small egg tray making machine consists of 1 transfer surface and 3 forming surfaces. The transfer surface delivers the wet pulp, while the 3 forming surfaces simultaneously shape the wet trays. Each cycle produces 3 trays.

Technical Parameters

| Item | Parameter |

|---|---|

| Model | SL-3*1 |

| Output | 1,000 trays/hour |

| Power | 38 kW |

| Voltage | 380V / 50Hz |

| Weight | 2,500 kg |

| Main Machine Size | 2,600 × 2,200 × 1,900 mm |

| Paper Consumption | 80 kg/h |

| Water Consumption | 160 kg/h |

| Drying Method | Air drying / Drying box |

Type 2: SL-4*1

The SL-4×1 small egg tray making machine consists of 1 transfer surface and 4 forming surfaces. The transfer surface delivers the wet pulp, while the 4 forming surfaces shape the wet trays simultaneously. Each cycle produces 4 trays. Compared with the 3×1 model, it has a higher output while maintaining a simple structure and easy operation, making it suitable for small to medium-sized production lines.

Technical Parameters

| Item | Parameter |

|---|---|

| Model | SL-4*1 |

| Output | 1,500 trays/hour |

| Power | 38 kW |

| Voltage | 380V / 50Hz |

| Weight | 3,000 kg |

| Main Machine Size | 2,800 × 2,200 × 1,900 mm |

| Paper Consumption | 120 kg/h |

| Water Consumption | 240 kg/h |

| Drying Method | Air drying / Drying room |

Key Differences Between the Two Machines

| Comparison Item | SL-3*1 | SL-4*1 |

|---|---|---|

| Mold Positions | 3 | 4 |

| Output | 1,000 trays/hour | 1,500 trays/hour |

| Total Power | 38 kW | 38 kW |

| Main Machine Weight | 2,500 kg | 3,000 kg (more stable) |

| Paper Consumption | 80 kg/hour | 120 kg/hour |

| Water Consumption | 160 kg/hour | 240 kg/hour |

| Drying Configuration | Air drying / Drying box | Air drying / Drying room (for higher output) |

| Suitable For | Small farms / Startups | Small to medium egg tray factories / Capacity expansion |

Advantages of Small Egg Tray Machines

Simple and Stable Structure

The machines use single-side 3×1 or 4×1 forming systems, which are compact and have a low failure rate.

- SL-3*1: 3 mold positions

- SL-4*1: 4 mold positions

The single-side system reduces rotating and transmission parts, ensuring stable operation and easy maintenance.

High Efficiency and Low Energy Consumption

Both models have a power of 38 kW, producing 1,000–1,500 trays per hour. The energy-to-output ratio is reasonable, making them cost-effective among similar machines.

High Pulp Utilization

Vacuum forming ensures even pulp distribution and high absorption efficiency.

- Paper consumption: 80–120 kg/h

- Water consumption: 160–240 kg/h (most can be recycled)

Durable Materials

The frame is made of thick Q235 carbon steel, weighing 2,500–3,000 kg, ensuring stability and precise forming.

Molds can be aluminum or copper, corrosion-resistant, heat-resistant, long-lasting, and form neat trays.

Flexible Drying Options

Drying can be adapted to production and climate:

- Air drying (low cost, suitable for sunny areas)

- Drying box (for SL-3*1)

- Drying room (recommended for SL-4*1)

Flexible configuration meets various small-scale production needs.

Stable and Reliable Output

Precision vacuum forming ensures consistent tray quantity and quality per cycle.

- SL-3*1: 1,000 trays/hour

- SL-4*1: 1,500 trays/hour

Wet trays are uniform and consistent; dried trays are flat, strong, and reduce rework, improving overall production efficiency.

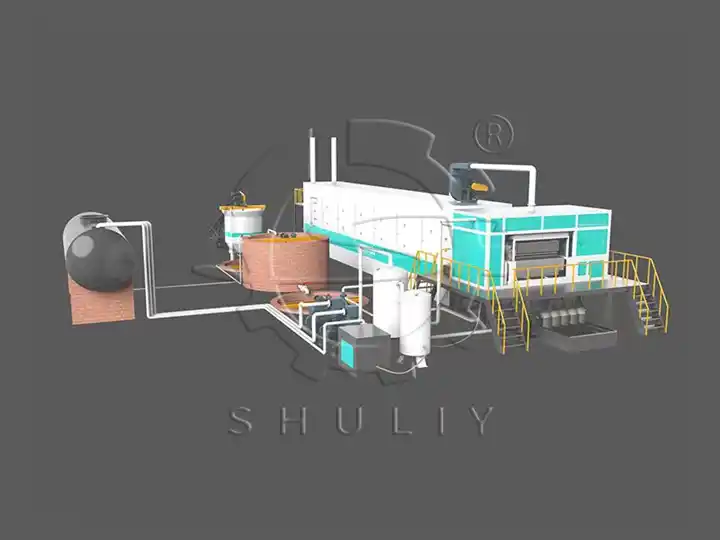

Small Egg Tray Production Line

The small egg tray production line mainly consists of the following parts:

Pulping System

Waste newspaper, corrugated paper, and kraft paper are mixed with water, then stirred and beaten to form a uniform pulp.

Pulp concentration can be adjusted, and small amounts of waterproofing agents can be added to improve moisture resistance.

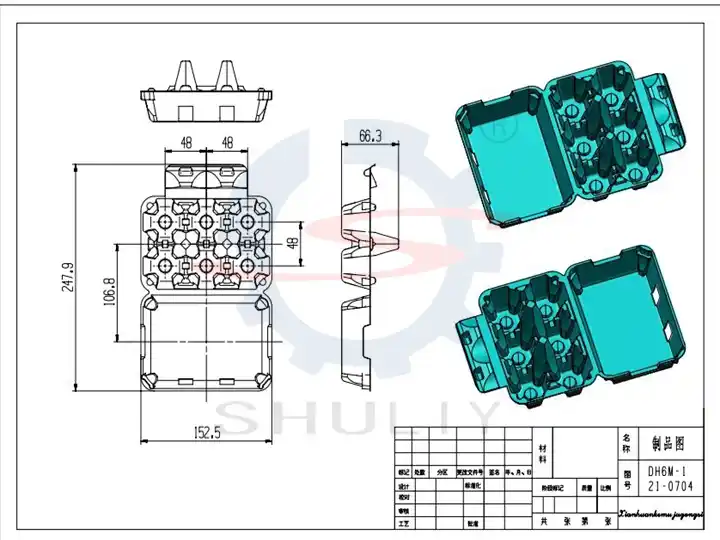

Forming System

Single-sided molds (3*1 or 4*1) with vacuum suction are used to evenly form wet trays.

Each cycle can form multiple trays at once, improving production efficiency.

Drying System

Trays can be dried naturally or in a drying room to remove moisture, ensuring strong and flat finished products.

Hot Pressing (Optional)

For a more polished and smooth appearance, the trays can be processed with a small egg tray hot press.

Packaging and Stacking

Shuliy can provide egg tray packing machines to improve packaging efficiency

The complete production process is shown in the diagram.

Services Provided by Shuliy

Shuliy offers one-stop services to ensure efficient and safe operation of equipment:

- Solution Design: Customize production line plans based on output and space for stable and efficient operation.

- Installation & Commissioning: Provide on-site or remote guidance to quickly put equipment into use.

- Operation Training: Train operators in pulping, forming, drying, and maintenance processes.

- Technical Support & Spare Parts: Supply spare parts long-term and offer phone or remote technical support.

- After-Sales Maintenance: Provide regular inspections and maintenance suggestions to extend equipment life.

- Customization & Upgrades: Offer mold customization, equipment upgrades, and production line expansion services.

Mexico Farm Case

A Mexican customer recently ordered a small egg tray forming machine from Shuliy with a capacity of 1500 trays per hour. The machine was successfully shipped last weekend.

This high-efficiency equipment will be used at the customer’s duck farm to produce egg trays for storing duck eggs. It enables automated and efficient egg tray production, providing reliable support for the farm’s daily operations.