What is an egg tray made of?

An egg tray is a tool used to pack eggs. Its main function is to absorb shock and facilitate the transportation and sale of eggs. So what is the egg tray made of?

Raw materials for making egg trays

First of all, we need to understand the types of egg trays. Some are plastic egg cartons, and some are pulp egg trays. It is difficult for us to associate soft paper with egg trays that protect eggs. The most common egg tray is pulp egg trays. Although the plastic egg cartons are more exquisite in shape and can be made into a silent six-color appearance, the plastic egg trays are expensive and there is no paper pulp egg tray to be environmentally friendly. The raw material of the pulp egg tray is some waste paper or cardboard boxes, which are called “green packaging”

How do I start my own egg tray business?

Want to start the egg tray business needs to solve the demand problem, in addition to the source of raw materials. The production of egg trays also requires a larger production line and production site. If the local climate is relatively humid, an egg tray dryer is required.

How many eggs are in a tray?

How many eggs can be placed in an egg tray, this number is not certain, some may be more, you can put 30, and some may only put 12, it depends on the local customs requirements, the egg tray machine can customize the mold.

What can you use the egg trays machine for?

In addition to producing egg boxes, the egg tray machine can also produce fruit trays and drink trays. Handicraft shell. The main purpose is to make some protective equipment to facilitate transportation.

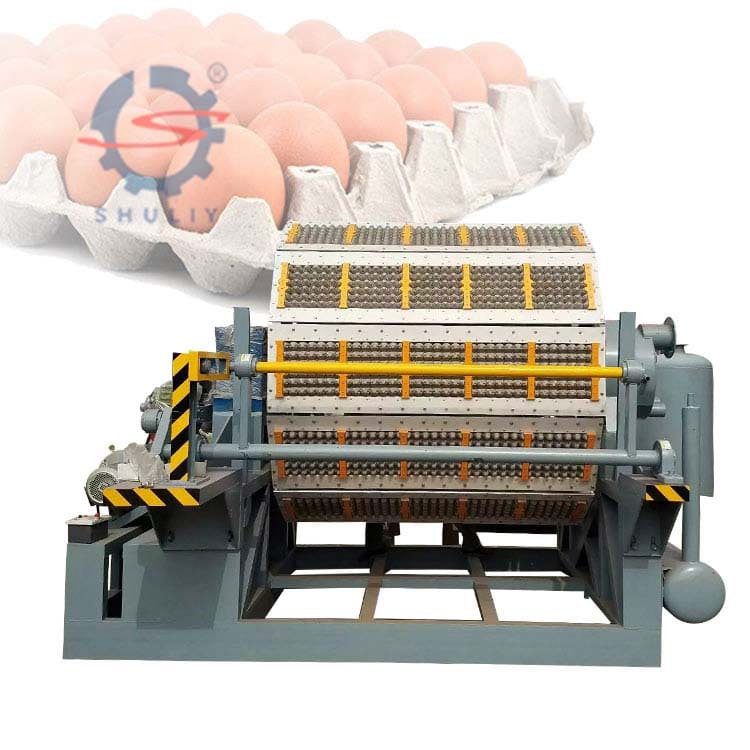

Working principle of egg tray machine

The waste paper is put into the pulper and decomposed into pulp fibers under the action of water flow and stirring; the pulp fibers enter the pulp storage tank. To make the product appearance more beautiful and clean, it is necessary to screen the slurry in the storage tank to remove the impurities in the fiber slurry. Then, the paper slurry is diluted to a certain concentration and finally pumped into the headbox of the forming machine. After being extruded, dried, and packed into storage