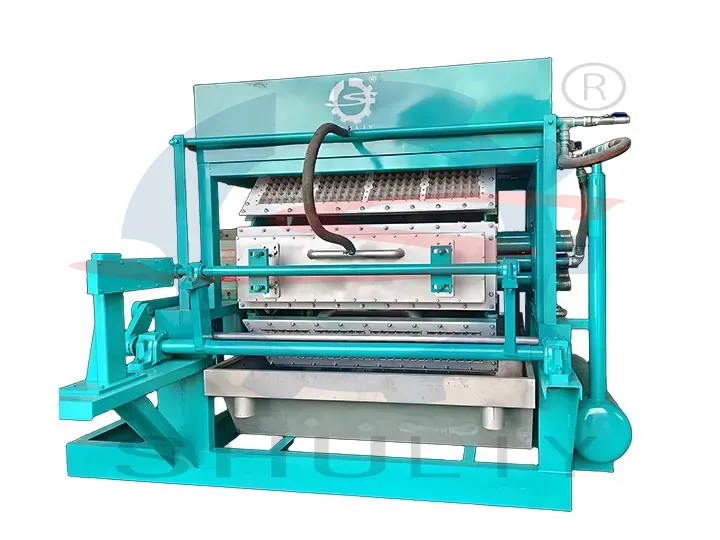

8 side egg tray machine

| Brand | Shuliy Machinery |

| Model | SL-4000-4X8; SL-5000-5X8; SL-7000-6X8 |

| Capacity | 4000-7000pcs/h |

| Power | 95kw; 120kw |

| Voltage | 380V,50HZ |

| Size | Reference Technical Parameter Table |

| Warranty | 12 months |

You can now ask our project managers for technical details

The 8 side egg tray machine, also known as a large-scale egg tray forming machine, is equipped with an 8-sided rotary drum. It enables high-speed, continuous production, making it especially suitable for factories with medium to large-scale output requirements.

SL-4000-4*8 can produce about 4000 eggshells per hour. Egg plate molds can be customized according to the buyer’s requirements. This equipment can be continuously produced and ensures production capacity. In addition, because the whole production process is recycled waste paper, no pollution sources, so it is called green environmental protection machinery.

Model SL-5000-5*8 egg tray machine can produce about 5000pcs egg trays per hour. It is 45 angle and an eight-plate rotary tray machine. Eight plates form a board, and all systems can be connected. This transfer arm makes a 90-degree reciprocating motion. The working efficiency is very high.

The SL-7000-6*8 is our company’s highest-capacity egg tray forming machine, with an output of up to 7,000 pieces per hour. It features an 8-sided rotary drum with 6 egg tray molds on each side, making it ideal for efficient, large-scale production in big factories.

What are the advantages of the 8-sided egg tray machine?

- Made with thickened carbon steel for durability and strong load capacity

- Aluminum alloy molds (optional stainless steel), lightweight and easy to dry and replace

- Non-stick, high-temperature Teflon coating available

- High-strength steel transmission system with wear-resistant bearings

- Stainless steel hydraulic pipes and copper valves, corrosion-resistant

- Waterproof and dustproof stainless steel control cabinet

- 8 side rotary design enables continuous operation without frequent stops

- Compatible with automatic drying and stacking systems

- Industrial-grade materials ensure over 10 years of continuous use

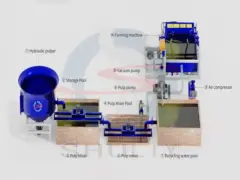

Structure & Production process of the 8-side rotary drum egg tray machine

The 8-sided tray making machine mainly consists of the pulping system, forming system, drying system, and packing system.

Parameters of the 8 side egg tray machine

| Model | SL-4000-4X8 | SL-5000-5X8 | SL-7000-6X8 |

| Capacity | 4000pcs/h | 5000pcs/h | 7000pcs/h |

| Power | 95kw | 95kw | 120kw |

| Voltage | 380V,50HZ | 380V,50HZ | 380V,50HZ |

| Weight | 7000kg | 8000kg | 10000kg |

| Pulp Usage | 320kg/h | 400kg/h | 480kg/h |

| Water Usage | 640kg/h | 800kg/h | 960kg/h |

| Size(mm) | 3250*2300*2500 | 3700*2300*2500 | 3200*2300*2500 |

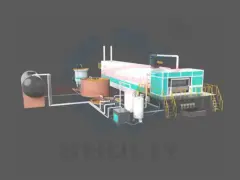

8 side egg tray production line

As a direct manufacturer, we can provide pulping machines, air compressors, dryers, and other equipment. We also offer reasonable land layout planning to help reduce your labor costs.

Sun Drying

| Item | Area |

| Machine footprint | 30–50 m² |

| Drying yard area | 1000 m² |

Civil Construction Dryers

| Model | Length (m) | Width (m) | Height (m) |

| SL-4×8 | >65 | >15 | >3 |

| SL-5×8 | >65 | >15 | >3 |

| SL-6×8 | = 80 | >15 | >3 |

| SL-8×8 | = 80 | >15 | >3 |

Multi-layer Dryers

| Model | Length (m) | Width (m) | Height (m) |

| SL-4×8 | 27.5 | 6 | 3.6 |

| SL-5×8 | 27.5 | 6 | 3.6 |

| SL-6×8 | 33.5 | 6 | 3.6 |

How to make egg trays?

Raw materials are mainly straw pulp, slurry, bamboo pulp, wood pulp, waste paperboard, waste paper box paper, waste white paper, paper mill tail pulp waste, etc. The raw material has a wide range of source and is easy to collect. The egg tray machine is the main machine for the egg tray production line.

Feeding the pulp in the pulp pool into the molding machine. The pulp is absorbed by the vacuum system, and the pulp is molded by the mold on the equipment. The water is absorbing and transporting back into the pulp pool through the vacuum pump. The water can be recycled.

After the mold adsorbs the water slurry, the transfer mold is discharged through the air compressor. The finished product is blown from the forming mold onto the transfer mold, and then it is sent out by the transfer mold.

Egg tray cost analysis table

| Cost Item | Description | Unit Cost per Tray (RMB) |

| Raw Material | 1 ton of waste paper can produce 12,000–15,000 trays (based on tray weight). Based on 80g per tray: 1,000,000g ÷ 80g = 12,500 trays Waste paper price: ¥1500/ton → 1500 ÷ 12,500 = ¥0.12 per tray | ¥0.12 |

| Labor | Sun drying: 6 workers; drying by machine: 4 workers. In China, Labor is often calculated by piecework: approx. ¥0.02 per tray. | ¥0.02 |

| Electricity | Varies with capacity and power consumption. Higher output means lower cost per tray. | ¥0.02 |

| Drying Fuel | Coal (5000 kcal/kg) Wood (4000 kcal/kg) Natural Gas (8900 kcal/m³) Diesel (11,900 kcal/liter) | ¥0.03/pc ¥0.03/pc ¥0.06/pc ¥0.08/pc |

| Pigment (optional) | ¥12/kg pigment; 1 kg can produce approx. 3000–4000 trays | Approx. ¥0.003–0.004 |

Currency Conversion: $1(USD)=¥7.2(RMB)

Why egg tray equipment is so popular on the market?

Environmental friend: With the development of society, more and more people are paying attention to environmental protection issues. The environment is what people depend on for survival. So we have to protect the environment through various channels. Recycling of waste paper is a way to protect the environment. No pollution will occur during the production process.

Functions: The main function of the egg tray is shock absorption. Separate items, such as fragile items, to reduce the rate of breakage of items during transportation or storage.

Price: The egg tray machine has several models to choose from. If you want to start a business from small, this is a good choice. The investment is not high, and you can take back the investment when the machine starts to produce. Egg tray machine for sale at a reasonable price from Zhengzhou Shuliy Machinery.

Clients we work with

Shipping cases