Fruit Tray Production Line

| Brand | Shuliy Machinery |

| Model | SL Series |

| Capacity | 1000-7000pcs/h |

| Power | 38-120kw |

| Voltage | 380V,50HZ |

| Size | Reference Technical Parameter Table |

| Warranty | 12 months |

You can now ask our project managers for technical details

The fruit tray production line has two types: fully automatic and semi-automatic. It is an eco-friendly machine used to make pulp trays for packaging fruits such as apples, oranges, pears, mangoes, and strawberries.

This line uses waste paper and other recyclable materials as raw materials. It produces fruit trays through pulping, molding, drying, and hot pressing processes.

Shuliy provides customized solutions for molds, forming systems, drying systems, and auxiliary equipment according to different fruits or vegetables. We can produce the most suitable and high-quality fruit trays for you based on your budget.

This industrial fruit tray production line can produce 1000–7000 pcs per hour, meeting the production needs of various enterprises.

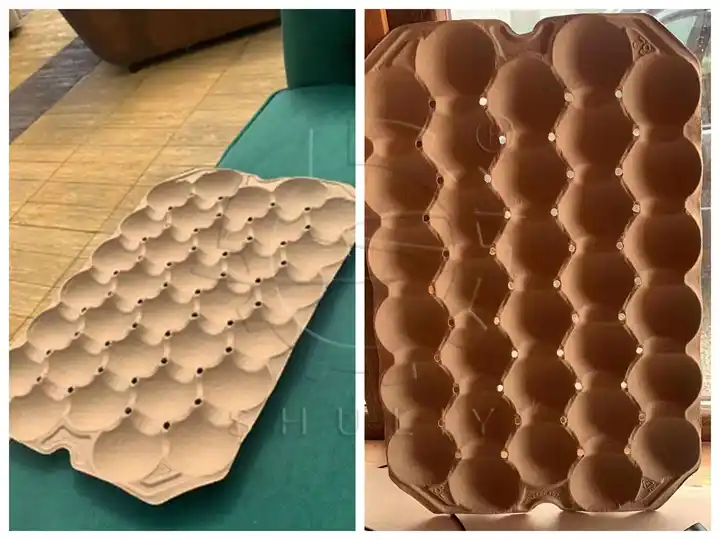

What is a pulp fruit tray?

A pulp fruit tray is an eco-friendly packaging tray made by molding waste paper pulp. It is mainly used to protect, store, and display fruits. It is made through processes such as pulp forming, dehydration and drying, and hot pressing. It is commonly used for packaging apples, oranges, pears, kiwis, mangoes, and other fruits. This tray can replace traditional plastic or foam packaging and has advantages like being eco-friendly, biodegradable, shockproof, and pressure-resistant. It is a widely promoted green packaging product internationally.

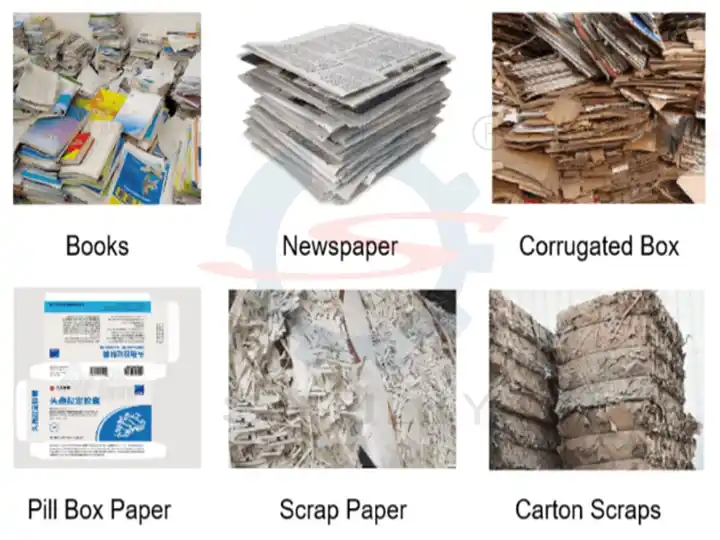

Raw materials

The main raw materials are waste newspapers, used cardboard, old book paper, and paper mill residues.

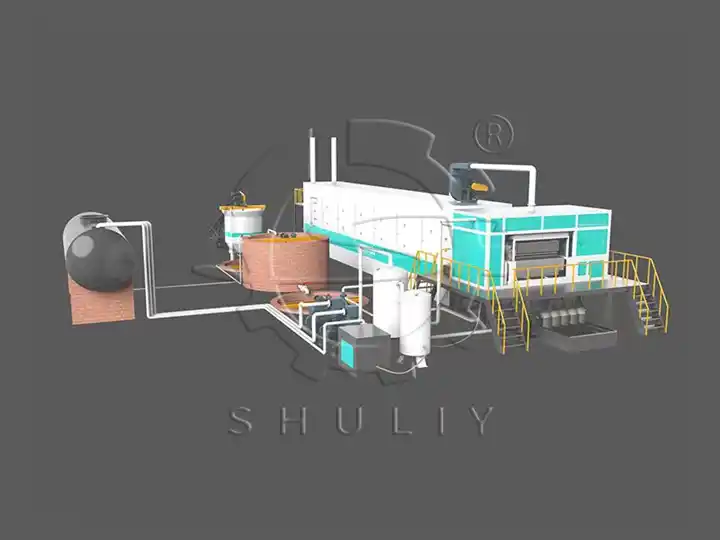

Components of a fruit tray production line

A fruit tray production line consists of a pulping system, molding system, drying system, hot-pressing machine, and packing machine.

What is the working process of a fruit tray production line?

Step 1: Pulping

Waste paper is added to the pulper with water and mixed to form pulp. The pulping concentration is usually 3%–5%, and the stock concentration in the storage tank is 1.0%–1.5%. Dilution helps with mixing and homogenization.

Step 2: Molding

The pulp is sent to the molding machine through pipes. A vacuum system pulls the pulp onto metal molds to form wet trays. Molds can be customized for different fruits.

Step 3: Drying

Wet trays are dried in the drying system at 160–200°C. Drying methods include:

- Metal drying line (high automation)

- Brick hot-air drying room (economical)

- Air-drying (for small-scale production)

Step 4: Hot-pressing

To improve appearance, trays are shaped under high temperature with a hot-press machine, making edges smooth, surfaces flat, and strength higher.

Step 5: Packing

Dried fruit trays are counted and packed for easy transportation.

Technical parameters

| Model | Capacity | Power | Voltage | Weight | Pulp Usage | Water Usage | Size(mm) |

| SL-1000-3X1 | 1000pcs/h | 38kw | 380V,50HZ | 2500kg | 80kg/h | 160kg/h | 2600*2200*1900 |

| SL-1500-4X1 | 1500pcs/h | 38kw | 380V,50HZ | 3000kg | 120kg/h | 240kg/h | 2800*2200*1900 |

| SL-2500-3X4 | 2500pcs/h | 55kw | 380V,50HZ | 4000kg | 200kg/h | 400kg/h | 2900*1800*1800 |

| SL-3000-4X4 | 3000pcs/h | 60kw | 380V,50HZ | 4800kg | 240kg/h | 480kg/h | 3250*1800*1800 |

| SL-4000-4X8 | 4000pcs/h | 95kw | 380V,50HZ | 7000kg | 320kg/h | 640kg/h | 3250*2300*2500 |

| SL-5000-5X8 | 5000pcs/h | 95kw | 380V,50HZ | 8000kg | 400kg/h | 800kg/h | 3700*2300*2500 |

| SL-7000-6X8 | 7000pcs/h | 120kw | 380V,50HZ | 10000kg | 480kg/h | 960kg/h | 3200*2300*2500 |

Advantages of a molded pulp fruit tray production line

Wide capacity range

Produces 1,000–7,000 trays per hour. Multiple models available to meet small to large factory needs.

Advanced drying system

Hot-air or multi-layer mesh drying ensures fast speed and high yield.

Reasonable energy consumption

Total power ranges from 38 kW to 120 kW, using high-efficiency motors to reduce running costs by 15%. The drying system supports hot-air circulation, increasing heat utilization to over 85%. Energy consumption is about 5–8 kWh per 1,000 trays, much lower than similar equipment.

Stable process

Uses vacuum suction + air-pressure demolding. Forming precision error ≤ ±0.3 mm, finished product rate ≥ 98%. Pulp concentration, vacuum time, and mold temperature are precisely controlled for uniform thickness, smooth edges, and flat surfaces.

Sturdy structure

The machine is made of carbon steel or stainless steel. Molds are made of aluminum or copper alloy, wear-resistant and heat-resistant, ensuring long life and stable operation.

Pulp and water recycling

Pulp usage is 80–480 kg/h, water consumption 160–960 L/h. Water is recycled with an average rate of over 85%, saving resources and protecting the environment.

Intelligent control

PLC system monitors pulp level, temperature, and vacuum. Features one-touch start/stop, automatic alarm, and counting for easy operation.

Customizable molds

Quick mold changes for apples, oranges, pears, etc., allowing one machine for multiple fruit types.

High automation

An optional stacking and packing system increases production efficiency by 30% and reduces labor by ~40%.

Global compatibility

Voltage can be customized for export to different countries.

Applications

- Fruit Trays: Apple tray, orange tray, pear tray, kiwi tray, mango tray, and other fruit or vegetable packaging trays.

- Extended Uses: Egg trays, wine bottle trays, cup trays, electronic product trays, and other pulp-molded packaging.

Installation drawing example

Below is a sample drawing we made for a customer, for your reference. For more details, please contact us.

Export case

In April 2024, an SL-4000 fruit tray production line was exported to Chile for apple tray production, with a daily output of about 30,000 trays.