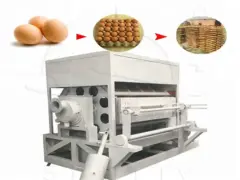

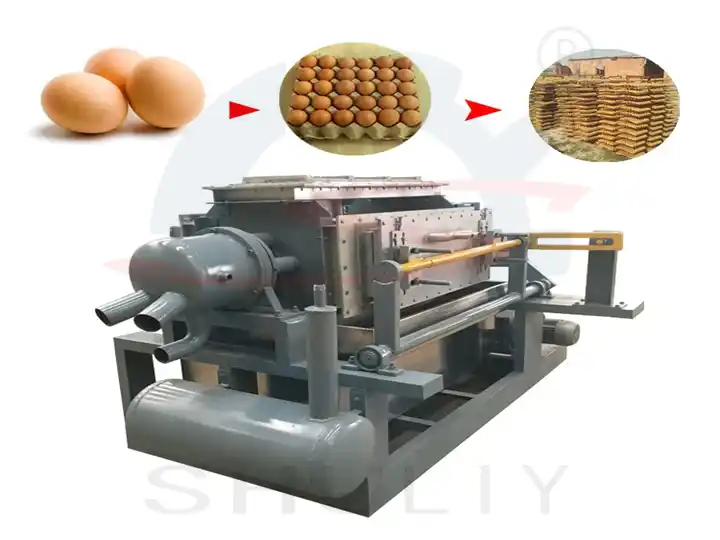

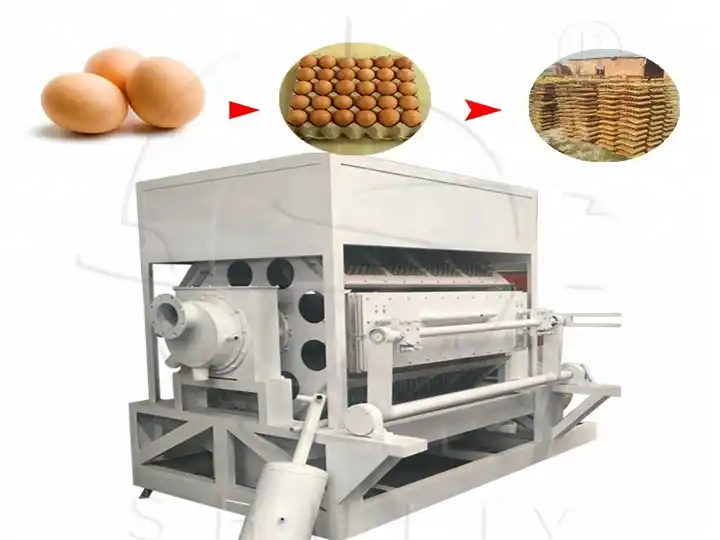

Egg carton making machine

| Model | SL Series |

| Capacity | 1000-7000pcs/h |

| Power | 38-120kw |

| Voltage | 380V,50HZ |

| Size | Reference Technical Parameter Table |

| Warranty period | 12 Months |

You can now ask our project managers for technical details

The egg carton making machine is the most important machine in the egg tray production line. This machine adopts the principle of hot press forming. The paper pulp transformed into fiber suspension is evenly coated on the surface of the mold, and then it is pressed to form the egg tray.

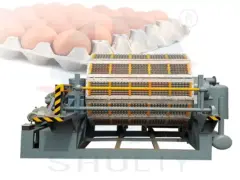

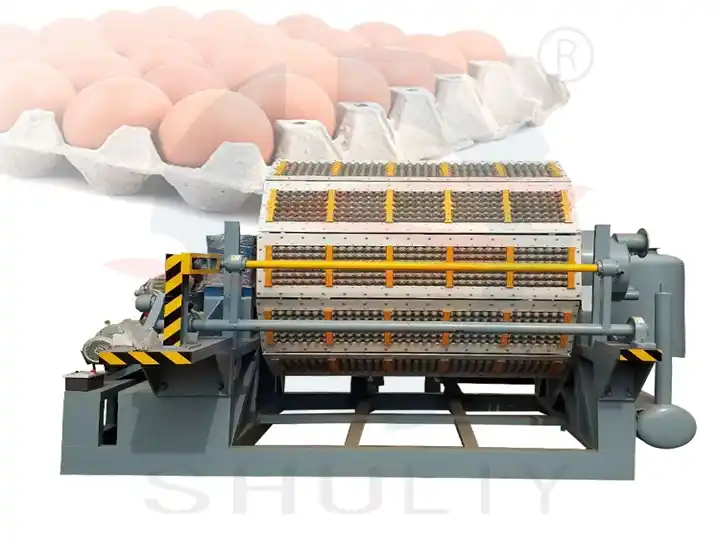

The egg carton making machine can be divided into single-sided egg tray machines and multi-sided egg tray machines. The multi-sided egg carrier can also be divided into the 4-sided egg carton making machine, the 8-sided egg tray machine, and the 12-sided egg tray machine.

Shuliy egg tray machines have a production capacity of 1,000–7,000 pcs/h, meeting the needs of both small and large businesses. According to your requirements, we can provide either semi-automatic or fully automatic production line configurations.

So far, we have supplied egg tray machines to more than 50 countries and regions, including Tanzania, Saudi Arabia, Mexico, Chad, Uzbekistan, Cameroon, Zambia, and the Philippines. Our products have been highly praised by customers worldwide.

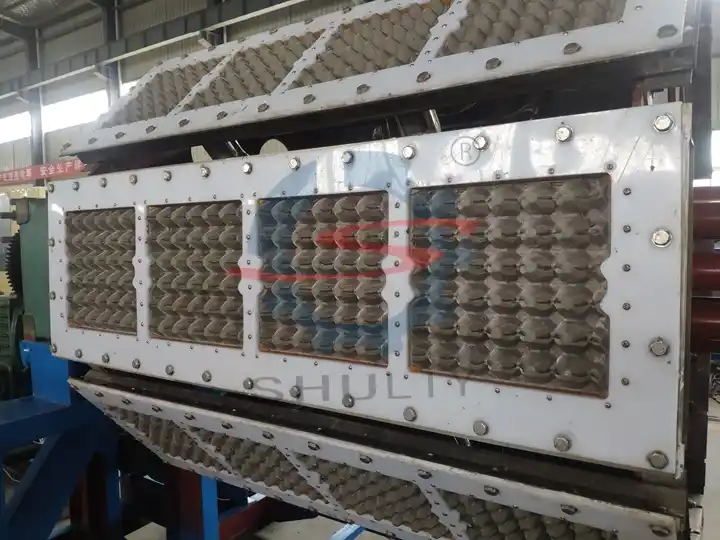

The structure of the egg carton making machine

The egg carton making machine is mainly composed of the drum-type molding motor, forming mold plate, transfer mold plate, vacuum pump, air compressor, storage tank, fuselage, and some other parts.

Drum-type molding motor

- Function: Provides stable power to drive the molding drum, ensuring uniform pulp adsorption on the mold.

- Data: Power range 7.5–15 kW, speed up to 1440 rpm, supporting a production capacity of 1000–7000 pcs/h.

- Key point: Motor power and speed directly determine production output and tray uniformity.

Forming a mold plate

- Function: Contacts the pulp and uses vacuum suction to form the initial shape of fruit trays.

- Data: Mold accuracy within ±0.05 mm; tray thickness 1.0–3.0 mm; one mold plate can form 2–12 trays per cycle.

- Key point: Surface precision affects tray smoothness and load capacity. High-quality stainless-steel molds last over 1,000,000 forming cycles.

Pulping Machine

- Function: Breaks down waste paper or plant fibers into pulp by dispersing, separating, and homogenizing fibers, providing uniform raw material for tray forming.

- Data: Pulp concentration 3–5%; fiber separation efficiency ≥ 95%; impurity removal rate up to 90%; suitable fiber length 0.2–1.5 mm.

- Key point: Ensures high pulp uniformity, improving tray strength by 20–30% and reducing thickness errors to within ±0.2 mm.

Vacuum pump

- Function: Provides negative pressure to吸 pull pulp fibers onto the mold surface.

- Data: Pumping capacity 100–300 m³/h; vacuum degree -0.06 to -0.09 MPa.

- Key point: Higher vacuum levels improve fiber density and tray strength.

Air compressor

- Function: Supplies compressed air for mold release, ensuring trays detach quickly and completely.

- Data: Operating pressure 0.6–0.8 MPa; air output 1–3 m³/min.

- Key point: Stable air pressure reduces breakage rates and increases efficiency.

Storage tank

- Function: Stores compressed air and stabilizes air pressure for continuous operation.

- Data: Tank volume 0.3–1.0 m³; stable output pressure 0.6–0.8 MPa.

- Key point: Prevents frequent compressor starts and prolongs system life.

Fuselage

- Function: Houses the motor, molds, pipelines, and control systems, ensuring overall machine stability.

- Data: Constructed from carbon steel or stainless steel; designed for continuous 24/7 operation.

- Key point: Strong structure ensures long service life (≥10 years).

Other auxiliary parts

- Pipeline system: Connects the vacuum pump, compressor, and molds; pipe diameter Φ25–Φ50 mm, ensuring fast air circulation.

- Electrical control system: PLC automation with timing precision ±0.5 seconds, offering one-button start/stop, production counting, and fault alarms.

How does the egg carton making machine work?

- Put the raw material into the pulper, add an appropriate amount of water, and make a fiber suspension after a long time of stirring.

- The water pump will suck the adjusted pulp into the water storage tank of the fruit tray forming machine.

- The pulp is adsorbed onto the forming mold by a vacuum system, and excess water slurry is transferred back to the storage tank via the vacuum adsorption system for reuse.

- Under the action of the air compressor, the molding die and the transfer mold are combined to press the pulp into the egg carton.

- The pressed egg tray will be sent out by the transfer mold to enter the next drying process.

The naming of egg tray making machines

Model introduction of the egg carton machine (taking SL-5 * 8 as an example)

- SL: Abbreviation of our company name

- 5: Number of dies on the die plate

- 8: 8 mold plates

Classification of egg carton making machines

Next, I will introduce the egg tray machines as single-side egg tray machines and multi-side egg tray machines in sequence, along with their technical parameters.

Single-sided egg carton forming machine

Introduction

The single-sided egg tray machine is also called a single-sided fruit carton forming machine, and the output is about 1000-2000 per hour. This machine has only one forming die plate, so it is also called a flap-type egg carton making machine. This model is currently one of the most popular models and is ideal for small and medium investors and novices.

Parameters

| Model | Capacity | Water paper | Water consumption | Electricity consumption | Worker |

| SL-3*1 | 1000-1500pcs/h | 120kg/h | 300kg/h | 32kw/h | 3-4 |

| SL-4*1 | 1500-2000PCS/h | 160kg/h | 380kg/h | 45kw/h | 3-4 |

4-sided egg carton making machine

Introduction

he four-sided egg tray forming machine is mainly composed of four mold plates with an angle of 90 degrees. Form a rotating cube. Due to the machine’s rotatable production, it saves waiting time and increases work efficiency. The machine can produce 2000-3500 egg trays per hour.

| Model | Capacity | Water paper | Water consumption | Electricity consumption | Worker |

| SL-3*4 | 2000-2500pcs/h | 200kg/h | 450kg/h | 58kw/h | 4-5 |

| SL-4*4 | 3000-3500pcs/h | 280kg/h | 560kg/h | 78kw/h | 4-5 |

8-sided egg carton making machine

Introduction

This egg carton making machine has eight mold plates with an angle of 45 degrees for continuous operation. The machine’s transfer arm can perform 90-degree reciprocating work with high efficiency. This machine is a large-volume machine. The output can reach 4000-5000 egg trays per hour.

Parameters

| Model | Capacity | Water paper | Water consumption | Electricity consumption | Worker |

| SL-4*8 | 4000pcs/h | 320kg/h | 600kg/h | 80kw/h | 5-6 |

| SL-5*8 | 5000pcs/h | 400kg/h | 750kg/h | 85kw/h | 3-4 |

12-sided egg carton making machine

Introduction

The productivity of the fruit tray making machine is currently the highest. There are 12 mold plates that are constantly rotating to make egg trays.

Parameters

| Model | Capacity | Water paper | Water consumption | Electricity consumption | Worker |

| SL-5*12 | 6000pcs/h | 480kg/h | 900kg/h | 90kw/h | 3-4 |

| SL-6*12 | 8000pcs/h | 640kg/h | 1040kg/h | 100kw/h | 3-4 |

Application market of egg carton machine

The final product of the egg carton making machine is mainly related to the mold, and different products can be produced by replacing different molds. At present, this machine is mainly used in the production of egg trays, wine trays, apple trays, toy mold holders, electronic component packaging and so on. It has good shock-proof and buffer function, and can avoid collision during transportation.

Egg Carton making machine production line

As a factory that manufactures egg tray machines, we provide complete egg tray production lines, including semi-automatic and fully automatic options. We can also design the machine layout and installation according to your factory plan.

Why choose Shuliy egg carton forming machine?

- Save labor costs. Mechanized production instead of manual labor can save a lot of labor costs.

- Wide application and simple mold replacement. Different products can be produced by simply changing the mold, which can be widely used in the packaging of fruits, alcohol, medical equipment, electronic components and the like.

- Well-made. The gap between the molds can affect the tightness of the final product. The egg carton making machine is equipped with stainless steel, the gap between the molds does not exceed 2mm.

- Environmentally friendly. The raw material is waste paper, and the water in the production process can be recycled, so almost no waste-water is generated and no burden is placed on the environment.

- Good pre-sales and after-sales service. the long warranty period of the fruit tray making machine.