Shoe Tray Production Line

| Brand | Shuliy Machinery |

| Model | SL Series |

| Capacity | 1000-7000pcs/h |

| Power | 38-120kw |

| Voltage | 380V,50HZ |

| Size | Reference Technical Parameter Table |

| Warranty | 12 Months |

You can now ask our project managers for technical details

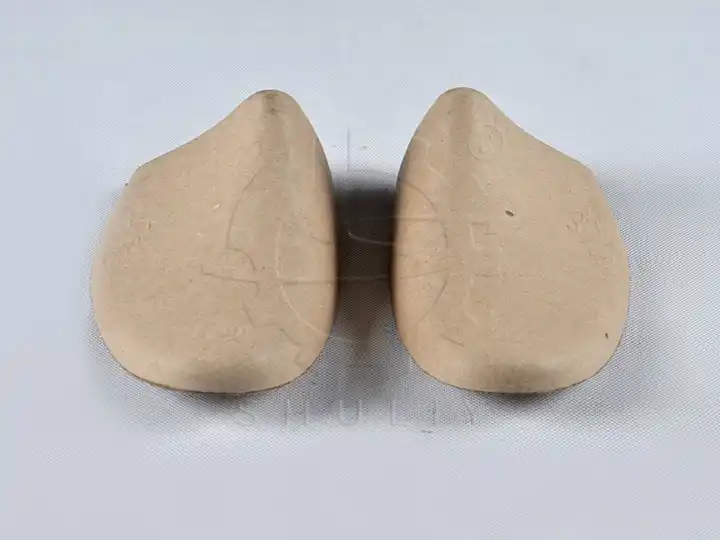

The shoe tray production line uses waste paper pulp as raw material. It produces eco-friendly pulp packaging products such as shoe trays, insoles, shoe bases, and shoe box liners through pulping, molding, demolding, drying, and trimming processes.

This production line is available in both fully automatic and semi-automatic types. Shuliy can design the most suitable production plan according to your needs and budget.

Depending on the machine model, the output can reach 1,000–7,000 pairs per hour. The molds can also be customized to add text or other surface designs to the shoe trays.

Our production line can produce trays for different types of shoes, such as leather shoes, sports shoes, casual shoes, and children’s shoes—simply by changing the forming molds.

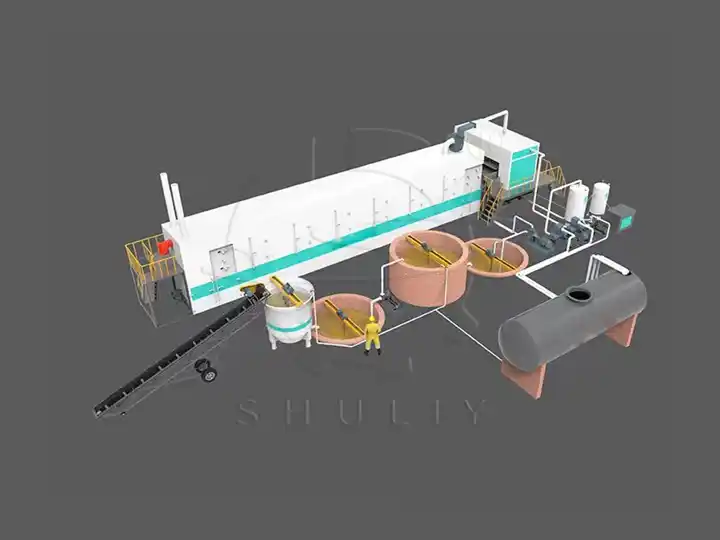

Main Equipment of the Shoe Tray Production Line

A standard shoe tray production line usually includes the following main parts:

- Pulp tank and pulp pump: used for storing and transferring pulp.

- Forming machine: the core molding unit, equipped with replaceable molds.

- Vacuum pump and air compressor system: responsible for pulp suction and demolding.

- Drying equipment: available with electric heating or hot air drying options.

- Control system: PLC touchscreen control, easy and intuitive to operate.

- Pulper and pulping equipment: used to process waste paper into pulp.

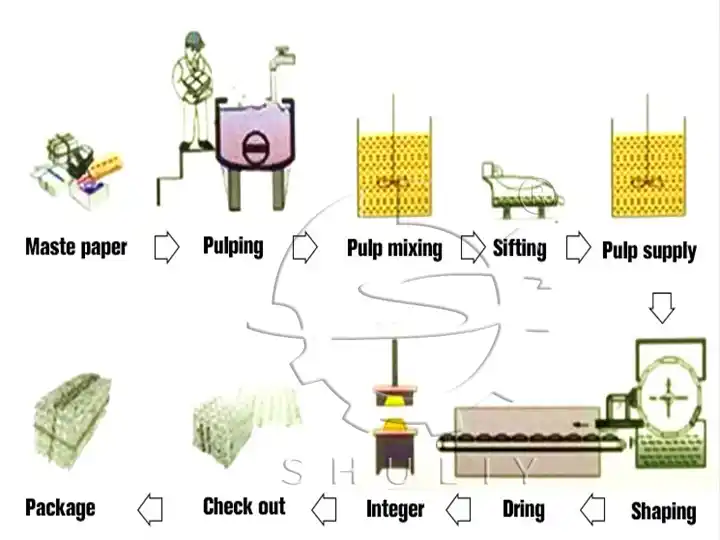

Production Process

The main process of the shoe tray production line includes:

Pulping → Forming → Drying → Trimming & Packaging

Pulping System

Waste paper (such as newspapers, corrugated paper, or old books) is crushed by a pulper and mixed with water to form uniform pulp.

The pulp concentration is usually 3%–5%, depending on the raw materials used.

Forming System

During forming, the pulp concentration is kept at 0.8%–1.2% to ensure even pulp absorption and accurate molding.

The mold is dipped into the pulp tank, and the vacuum pump sucks the pulp onto the mold surface to form a wet tray.

Drying System

The trays are dried and shaped by hot air, electric heating drying chambers, or continuous mesh belt dryers. Natural drying can also be used to reduce costs.

Trimming & Packaging

The edges of the trays are trimmed, and the finished products are packed and stored using a packing machine.

Models and Capacity

| Model | Capacity | Power | Voltage | Weight | Pulp Usage | Water Usage | Size(mm) |

| SL-1000-3X1 | 1000pcs/h | 38kw | 380V,50HZ | 2500kg | 80kg/h | 160kg/h | 2600*2200*1900 |

| SL-1500-4X1 | 1500pcs/h | 38kw | 380V,50HZ | 3000kg | 120kg/h | 240kg/h | 2800*2200*1900 |

| SL-2500-3X4 | 2500pcs/h | 55kw | 380V,50HZ | 4000kg | 200kg/h | 400kg/h | 2900*1800*1800 |

| SL-3000-4X4 | 3000pcs/h | 60kw | 380V,50HZ | 4800kg | 240kg/h | 480kg/h | 3250*1800*1800 |

| SL-4000-4X8 | 4000pcs/h | 95kw | 380V,50HZ | 7000kg | 320kg/h | 640kg/h | 3250*2300*2500 |

| SL-5000-5X8 | 5000pcs/h | 95kw | 380V,50HZ | 8000kg | 400kg/h | 800kg/h | 3700*2300*2500 |

| SL-7000-6X8 | 7000pcs/h | 120kw | 380V,50HZ | 10000kg | 480kg/h | 960kg/h | 3200*2300*2500 |

Shuliy offers various models of shoe tray forming machines, with a production capacity of 1,000 to 7,000 pairs per hour, suitable for different production scales.

Buying Guide

- SL-1000 Series (1,000–2,000 pairs/hour)

- Suitable for small shoe factories, packaging workshops, or startups.

- Typical models: SL-1000, SL-1500

- SL-3000 Series (2,500–4,000 pairs/hour)

- For medium-sized production lines, ideal for medium-scale shoe manufacturers or professional packaging companies.

- Typical models: SL-2500, SL-3000, SL-4000

- SL-7000 Series (5,000–7,000 pairs/hour)

- Typical models: SL-5000, SL-7000

- Suitable for large shoe factories, packaging enterprises, or export-oriented factories.

All models can be customized according to customer requirements, including mold size, drying system type, and automation level. For any specific needs, feel free to contact us.

Types of Shoe Tray Production Lines

Pulp shoe tray production lines are mainly divided into fully automatic and semi-automatic types, based on their level of automation.

The two types differ in structure, operation, and production efficiency.

Semi-Automatic Shoe Tray Production Line

Workflow:

Pulping → Forming → Manual transfer of wet trays → Drying → Trimming → Packaging

In this type, pulping and forming are usually done by machines, while demolding, transferring, and drying require manual work or simple mechanical assistance.

Features & Advantages:

- Low investment: fewer machines, lower energy consumption

- Easy operation: short training time, simple maintenance

- Small footprint: ideal for limited space

- Flexible for small batches and multiple varieties: easy mold changes for different shoe types and sizes

Suitable for:

- Small shoe factories or packaging workshops

- Start-up eco-friendly packaging businesses

- Pilot production lines or sample development

Typical Capacity:

Approximately 1,000–2,500 pairs per hour

Fully Automatic Shoe Tray Production Line

Workflow:

Automatic pulping → Automatic forming → Automatic demolding → Automatic drying → Automatic stacking & packaging

The entire line is controlled by a PLC system. Operators only need to set parameters on the control panel to complete the full process.

Features & Advantages:

- High efficiency: continuous operation with output of 3,000–7,000 pairs per hour

- Labor saving: fully automated control greatly reduces labor costs

- Consistent quality: automatic pulp application and vacuum forming ensure uniform thickness and smooth appearance

- Energy-efficient: equipped with automatic hot air drying and vacuum water recycling systems to reduce energy consumption

- Highly expandable: supports multi-station and multi-mold production, suitable for large orders

Suitable for:

- Large shoe manufacturers

- Export-oriented packaging factories

- E-commerce shoe brands and OEM factories

Why Choose Shuliy Shoe Tray Forming Machines?

Eco-friendly materials

Made from 100% recycled pulp, fully biodegradable and pollution-free, meeting international environmental standards.

High flexibility

Molds can be customized for different shoe types and sizes, supporting single trays, double trays, insoles, and liners. Molds can also be engraved with logos or textures to enhance product appearance.

Cost and space saving

Low raw material cost; products can be stacked and compressed for efficient transportation.

Stable performance and easy operation

Compact structure with PLC intelligent control system, simple operation, easy maintenance, and quick mold change.

Multi-purpose design

Can also produce cosmetic liners, electronics trays, wine box liners, small appliance packaging, and more.

Scalable and customizable

Suitable for small, medium, and large production scales, with adjustable automation, mold sizes, and production speed to meet diverse business needs.

Mold Design Recommendations

A good mold is key to product quality. Shuliy offers professional mold customization services, focusing on:

- Good ventilation: ensures smooth pulp absorption

- Smooth edges: reduces trimming work

- Surface finish: sandblasting or polishing to enhance texture

- Quick-change design: improves production efficiency

- Anti-corrosion treatment: extends mold lifespan