Pulping Equipment

| Brand | Shuliy Machinery |

| Model | SL Series |

| Capacity | 1.2 m³, 2.5 m³, 4 m³, 5 m³, 6 m³, 8 m³ |

| Power | 7.5kw-45kw |

| Warranty | 12 Months |

You can now ask our project managers for technical details

Pulping equipment, including the hydra pulper, pulp pump, and other parts. The equipment is mainly used to process the waste into paper pulp.

In pulping equipment, the core machine is the hydra pulper. Shuliy offers hydra pulpers with capacities of 1.2 m³, 2.5 m³, 4 m³, 5 m³, 6 m³, and 8 m³. They can be matched with all egg tray machines produced by our company, as well as all common types on the market. If you only need pulping equipment, we can also recommend suitable models based on your machine type.

The pulping machine mainly works by using the built-in impeller to rotate the water. With centrifugal force, the waste paper and water hit the baffle plates on the cylinder, which completes the pulping process. Normally, it takes about 20–40 minutes to make one batch of pulp, but the time may vary depending on the toughness of the waste paper. Our pulping machine is suitable for many raw materials. If your pulp material is special, feel free to contact us through the pop-up window for consultation.

This is the first step for egg tray making, which is also an essential machine for the egg tray production line. Zhengzhou Shuliy Machinery has a professional technology that the pulp equipment can improve the efficiency and the finished product. The more broken the pulp, the better the effect of the egg tray.

Functions of the pulping equipment

Pulping equipment is a necessary machine in the entire production line for making a high-quality egg tray. The better the effect of the pulp is disintegrated, the higher the quality of the finished product.

- Soaking and softening: Mix waste paper with water to fully expand and soften the fibers.

- Fiber dispersion: Use the impeller to stir and impact, evenly separating fibers in the pulp.

- Impurity removal: Centrifugal force and baffle plates separate large impurities and insoluble materials.

- Pulp consistency adjustment: Control the thickness of the pulp.

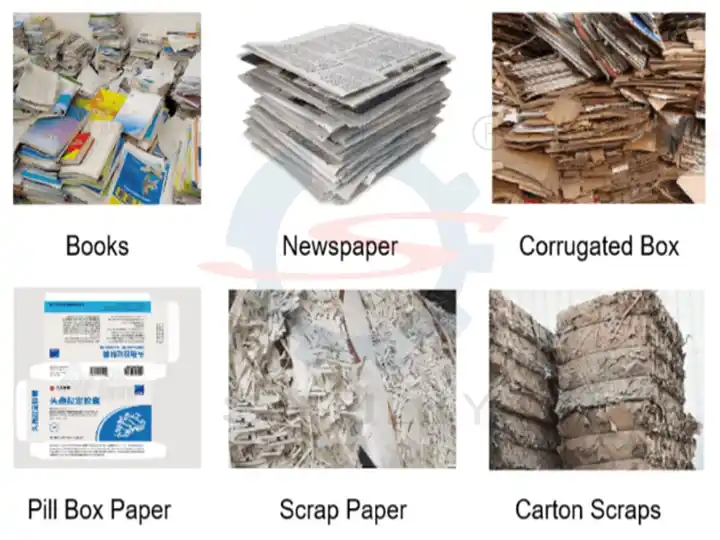

- Suitable for various materials: Can process corrugated paper, cardboard, old newspapers and books, crop straw, and industrial paper.

What raw materials can pulping equipment process?

Waste paper

- Old newspapers (ONP)

- Cardboard (OCC)

- Corrugated paper

- Books or printing paper

Crop straw

- Corn stalks

- Rice straw

- Wheat straw

Industrial or household waste paper

- Cardboard pieces

- Paper bags

- Paper cups, paperboard packaging, etc.

Other fibrous materials

- Wood pulp

- Cotton fibers or textile waste

- PE-coated waste paper

- Paper mill residues and other scraps

Advantages of the pulping equipment

- Multiple capacities available: offered in 1.2 m³, 2.5 m³, 4 m³, 5 m³, 6 m³, and 8 m³ to meet different production needs.

- Flexible power options: from 7.5 kW to 45 kW, compatible with various egg tray machines, including common models on the market.

- High-efficiency pulping: high-speed impeller design enables rapid stirring and impact, ensuring uniform fiber dispersion and high pulping efficiency.

- Durable materials: body made of high-quality carbon steel or stainless steel, with wear-resistant and corrosion-resistant parts for long service life.

- Compatible with various raw materials: can process waste paper, crop straw, wood pulp, cotton fibers, and other fibrous materials, including PE-coated waste paper and paper mill residues.

- Easy to operate: PLC controls the on/off function, compact design, easy to feed and clean, and low maintenance.

- Pulp consistency is controllable: concentration is adjustable to meet different production needs.

- High efficiency and energy-saving: low power consumption, stable operation, and low noise.

- Special shape design: Higher degree of fragmentation and higher efficiency.

Main parts of the pulping equipment

Pulping equipment mainly consists of a hydra pulper and a pulping pump.

Hydra pulper

The pulper consists of a machine body, impeller, baffle plates, feeding system, discharge outlet, transmission system, and control system.

Working principle

The hydra pulper is a circular tank hydraulic pulping machine, which is a special equipment for dismantling various waste papers. The special design shape changes the flow path of the slurry in the tank, which moves the vortex generated by the water from the center to the side so that the slurry is submerged as soon as possible. Therefore, the number of times the impeller in the tank is in contact with the slurry is rapidly increased to improve the efficiency of disintegration.

| Capacity | Power | Applicable Machines |

|---|---|---|

| 1.2 m³ | 7.5 kW | SL-3*1, SL-4*1 |

| 2.5 m³ | 11 kW | SL-3*1, SL-4*4 |

| 4 m³ | 18.5 kW | SL-4*8 |

| 5 m³ | 22 kW | SL-5*8 |

| 6 m³ | 30 kW | SL-6*8 |

| 8 m³ | 45 kW | SL-6*8 |

Pulp pump

The pulping pump consists of a pump body, impeller, shaft, pump cover, bearings, sealing device, and drive unit.

Working principle

Pulp pump is used for sending the paper pulp. At first, the pump sends the paper pulp into a pulp pool after the paper is crushed by the hydrapulper. Then the water from another pool is also sent to the pulp pool. The water and the paper pulp are mixed in the pulp pool. The ratio of pulp to water is 1:10. All the steps need a pump to deliver. The pump connects the all production system, which can ensure the production of normally.

| Size | Power | Applicable Machines |

|---|---|---|

| 3-inch pump | 3 kW | SL-3*1, SL-4*1, SL-3*4 |

| 4-inch pump | 4 kW | SL-4*4, SL-4*8 |

| 5-inch pump | 5.5 kW | SL-5*8, SL-6*8 |

| 6-inch pump | 7.5 kW | SL-6*8, SL-8*8 |

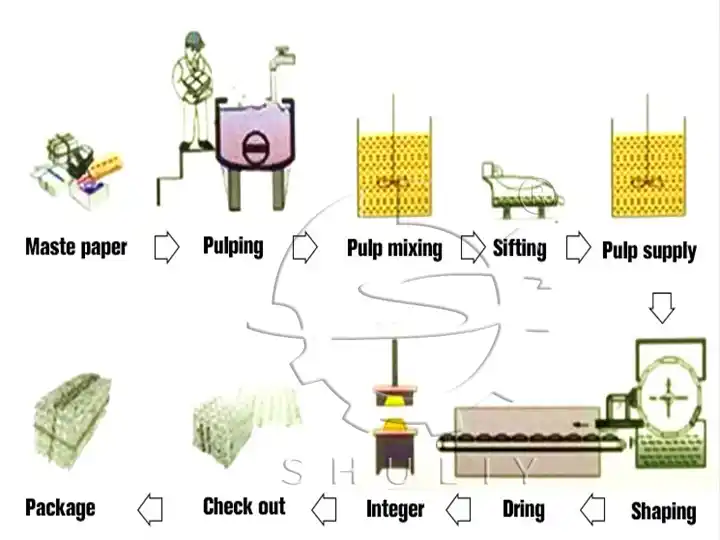

Pulping production process

When pulping, there are three pools. One is a pulping pool, one is a water pool, and the other one is a pulp supply pool.

The pulp and water are delivered to the pulp supply pool by the pulping equipment according to a certain proportion. Then, processed paper pulp is sent to the egg tray mold machine by the pulp pump. Every step of the process is inseparable from the pulp pump.

Finally, if you have any questions about this machine, pls contact us now! We will provide our professional service and technology.

Recommended pulp concentration

The pulp concentration in a pulper is usually adjusted according to the raw material and product requirements. Typical ranges are:

- Pulp concentration: about 2%–8% (suitable for standard egg trays and molded pulp products)

- Hard or special products: can be increased to 8%–12%

- Soft materials or recycled paper: usually kept at 2%–5% to ensure uniform fiber dispersion

Application of the pulping equipment in egg Tray production line

In the egg tray production line, the pulping machine plays a crucial role. Its process steps are summarized as follows:

- Feeding: Waste paper or other raw materials are fed into the pulping machine.

- Soaking: The raw materials are mixed with water to soften the fibers.

- Pulping & Stirring: The impeller rotates at high speed, breaking down the materials into a pulp of a certain consistency.

- Impact & Dispersion: The pulp hits the deflector plates, ensuring fibers are evenly dispersed and large impurities are removed.

- Pulp consistency adjustment: The pulp’s concentration is adjusted according to molding requirements, typically 6%–8%; pigments can also be added to produce colored egg trays.

- Discharging: The prepared pulp is sent through the outlet to the molding machine or storage tank.

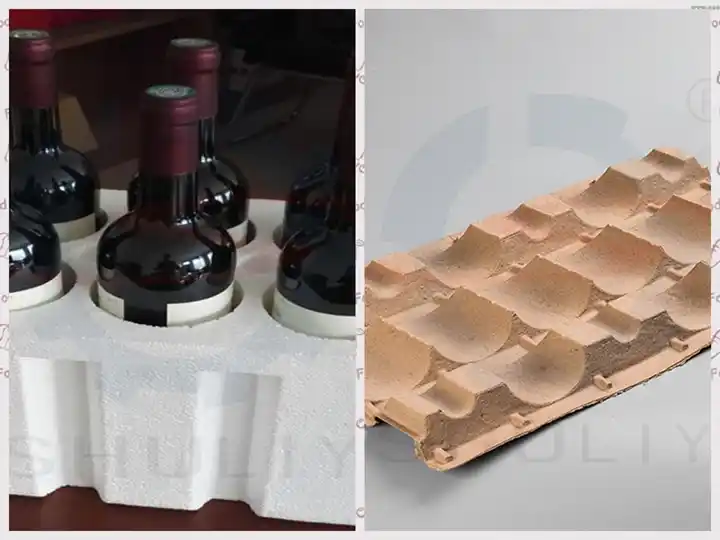

We can provide the complete egg tray production line, including everything from small accessories to full machines, all manufactured in our factory. Whether you want to produce egg trays, wine trays, coffee cup trays, fruit trays, plant pot trays, or fast food trays, we can make it possible. Inquiries are welcome.