4000-7000pcs/hr Egg Carton Machine

| Model | SL-4*8, SL-5*8, and SL-6*8 |

| Capacity | 4000-7000pcs/hr |

| Water consumption | 640-960kg/h |

| Pulp consumption | 320-480kg/h |

| Warranty | 12 months |

| Brand | Shuliy Machinery |

You can now ask our project managers for technical details

Shuliy offers large egg carton machines in three models: SL-4*8, SL-5*8, and SL-6*8. Their capacity ranges from 4,000 to 7,000 pcs/hr. Customers can choose based on actual production needs and factory conditions. For machines above 10,000 pcs/hr, we also offer custom solutions.

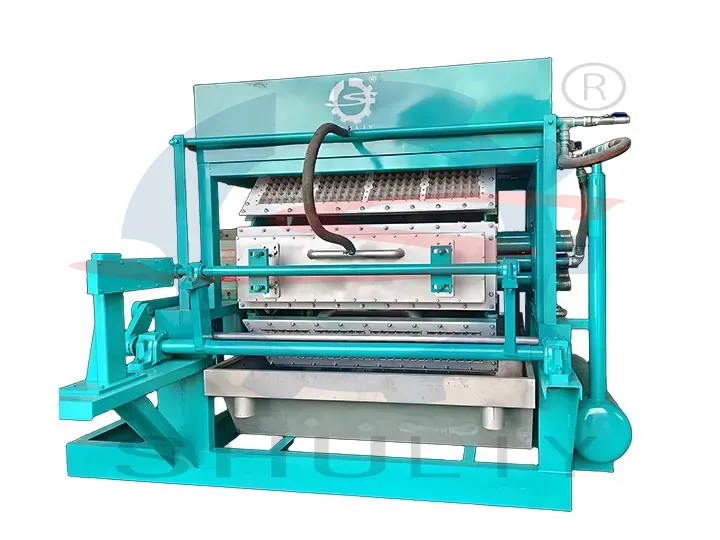

This 4,000–7,000 pcs/hr large egg carton machine is designed for medium to large egg carton factories. It is a fully automatic pulp molding machine that combines high efficiency, stable operation, and large-scale production. The series uses an 8-face rotary molding structure to produce standard pulp egg cartons continuously and reliably. It is widely used in egg packaging, logistics, and export packaging.

Shuliy is committed to providing these egg carton machines worldwide. Whether you are new to pulp egg carton production or looking to upgrade your equipment, we can offer tailored solutions, help design your factory layout, and plan your production process.

Large Egg Carton Machine Models

Type 1: SL-4*8

The SL-4*8 has 8 rotary faces and 1 conveyor face. Each rotary face has 4 forming molds. All four molds shape wet pulp trays at the same time, producing 32 egg cartons per full rotation.

Technical Specifications

| Item | Specification |

|---|---|

| Model | SL-4*8 |

| Capacity | 4000–5000 pcs/h |

| Power | 95 kW |

| Voltage | 380V, 50Hz |

| Weight | 7000 kg |

| Size (Molding Machine) | 3250 × 2300 × 2500 mm |

| Paper Consumption | 320 kg/h |

| Water Consumption | 640 kg/h |

| Drying Method | Brick kiln drying or multi-layer dryer |

Type 2: SL-5*8

The SL-5*8 has 8 rotary faces and 1 conveyor face. Each rotary face has 5 forming molds. All five molds shape wet pulp trays at the same time, producing 40 egg cartons per full rotation.

Technical Specifications

| Item | Specification |

|---|---|

| Model | SL-5*8 |

| Capacity | 5000–6000 pcs/h |

| Power | 95 kW |

| Voltage | 380V, 50Hz |

| Weight | 8000 kg |

| Size (Molding Machine) | 3700 × 2300 × 2500 mm |

| Paper Consumption | 400 kg/h |

| Water Consumption | 800 kg/h |

| Drying Method | Brick kiln drying or multi-layer dryer |

Type 3: SL-6*8

The SL-6*8 has 8 rotary faces and 1 conveyor face. Each rotary face has 6 forming molds. All six molds shape wet pulp trays at the same time, producing 48 egg cartons per full rotation.

Technical Specifications

| Item | Specification |

|---|---|

| Model | SL-6*8 |

| Capacity | 6000–7000 pcs/h |

| Power | 120 kW |

| Voltage | 380V, 50Hz |

| Weight | 10000 kg |

| Size (Molding Machine) | 3200 × 2300 × 2500 mm |

| Paper Consumption | 480 kg/h |

| Water Consumption | 960 kg/h |

| Drying Method | Brick kiln drying or multi-layer dryer |

Comparison of Three Models

| Model | Capacity (pcs/h) | Power (kW) | Pulp Consumption (kg/h) | Water Consumption (kg/h) |

|---|---|---|---|---|

| SL-4×8 | 4,000–5,000 | 95 | 320 | 640 |

| SL-5×8 | 5,000–6,000 | 95 | 400 | 800 |

| SL-6×8 | 6,000–7,000 | 120 | 480 | 960 |

Key Advantages

Stable Medium-to-High Capacity

- SL-4×8: 4,000–5,000 pcs/hr

- SL-5×8: 5,000–6,000 pcs/hr

- SL-6×8: 6,000–7,000 pcs/hr

Meets mainstream production needs for medium to large egg carton factories, balancing efficiency and stability.

Higher Output Efficiency

- SL-4×8: 95 kW

- SL-5×8: 95 kW

- SL-6×8: 120 kW

Production increases by 20–40% while power growth remains reasonable. Low energy consumption per unit, cost-effective.

High-Strength Steel Frame

The main machine uses a high-strength welded steel structure with fatigue resistance and corrosion resistance. Suitable for long-term continuous production, ensuring stable operation and low maintenance costs.

Compact Structure, High Space Utilization

- SL-4×8: 3250×2300×2500 mm

- SL-5×8: 3700×2300×2500 mm

- SL-6×8: 3200×2300×2500 mm

Delivers high output in limited factory space with flexible layout.

Efficient Multi-Face Rotary Molding

The 8-face rotary molding structure enables pulp suction, forming, and dewatering continuously. Increases production efficiency, reduces labor, and ensures uniform wall thickness and consistent size of egg cartons.

Flexible Drying Options

Formed egg cartons can use brick kiln drying, multi-layer dryers, or drying rooms. Configurable based on local energy conditions and investment budget.

Highlights of Large Egg Carton Making Machines

- The machine is made of thick carbon steel, offering high strength, stability, excellent load capacity, and long-term reliability.

- Standard aluminum molds are lightweight, heat quickly, and dry efficiently. Stainless steel or plastic molds can also be customized for different production needs.

- Mold surfaces can have high-temperature, non-stick Teflon coating to reduce sticking, improve demolding, and ensure consistent product quality.

- High-strength steel transmission system with wear-resistant bearings ensures smooth operation and low maintenance, suitable for long continuous production.

- Stainless steel hydraulic pipelines and copper valves provide excellent corrosion resistance for stable long-term hydraulic performance.

- Waterproof and dustproof stainless steel control cabinet ensures electrical safety and reliability in harsh industrial environments.

- Eight-face rotary molding design allows continuous operation without frequent stops, greatly improving production efficiency.

- Can seamlessly integrate with automatic drying and stacking systems for a fully automated egg carton production line.

- Industrial-grade durable materials throughout support over 10 years of continuous, stable use with proper maintenance.

How to Make Egg Cartons?

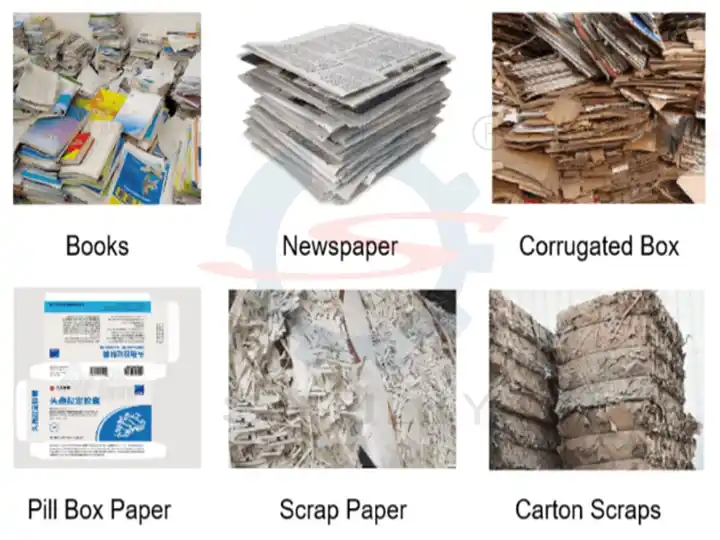

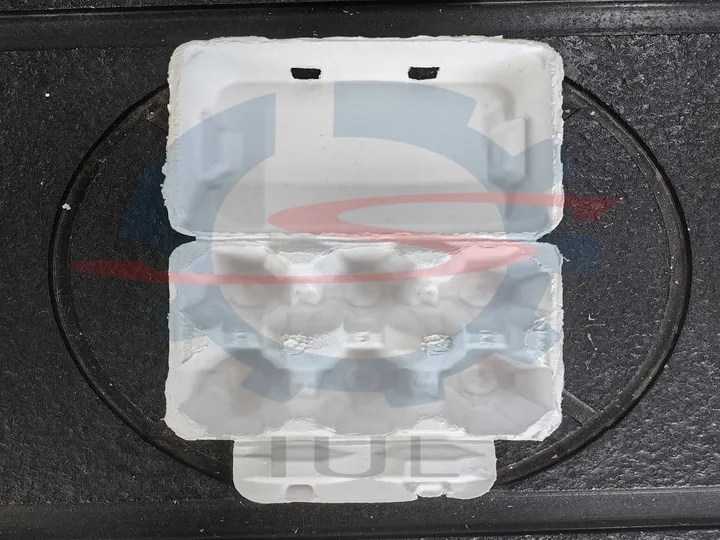

Large egg carton machines use waste paper, cardboard, old books and newspapers, paper mill pulp, bamboo pulp, or wood pulp as raw materials. The pulp is processed into a uniform slurry. The slurry is vacuum-formed on molds to quickly shape wet egg carton blanks. The wet blanks are then automatically demolded and sent to a drying line or air-drying area, producing strong, uniform egg cartons. The machine runs continuously and stably, suitable for 24-hour uninterrupted production.

Applications

- Packaging for eggs, duck eggs, and other poultry eggs

- Supporting egg processing factories and farms

- Pulp molding product factories

- Export-oriented eco-friendly packaging production lines

What Are the Costs of Using a Large Egg Carton Machine?

Besides the equipment purchase, daily production of egg cartons also involves the following expenses:

| Cost Item | Description | Unit Cost per Tray (RMB) |

| Raw Material | 1 ton of waste paper can produce 12,000–15,000 trays (based on tray weight). Based on 80g per tray: 1,000,000g ÷ 80g = 12,500 trays Waste paper price: ¥1500/ton → 1500 ÷ 12,500 = ¥0.12 per tray | ¥0.12 |

| Labor | Sun drying: 6 workers; drying by machine: 4 workers. In China, Labor is often calculated by piecework: approx. ¥0.02 per tray. | ¥0.02 |

| Electricity | Varies with capacity and power consumption. Higher output means lower cost per tray. | ¥0.02 |

| Drying Fuel | Coal (5000 kcal/kg) Wood (4000 kcal/kg) Natural Gas (8900 kcal/m³) Diesel (11,900 kcal/liter) | ¥0.03/pc ¥0.03/pc ¥0.06/pc ¥0.08/pc |

| Pigment (optional) | ¥12/kg pigment; 1 kg can produce approx. 3000–4000 trays | Approx. ¥0.003–0.004 |

$1(USD)=¥7.2(RMB)

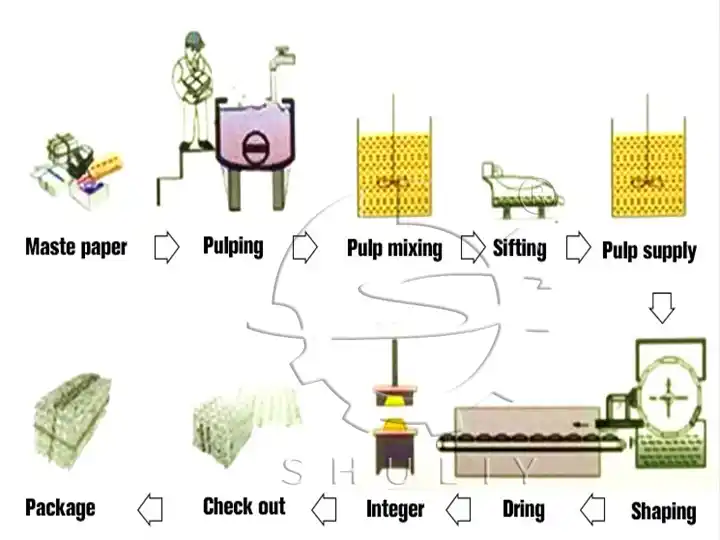

What Is the Process of Producing Egg Cartons?

Process Flow

Raw Material Preparation

Select eco-friendly materials such as waste paper and cardboard. Remove impurities to ensure stable pulp processing at 320–480 kg/h (SL-4×8–SL-6×8).

Pulping

Soak and beat the materials into uniform pulp. This ensures smooth molding and provides stable slurry for producing 4,000–7,000 egg cartons per hour.

Forming

The 8-face rotary molding structure sucks, dewaters, and demolds the pulp. It ensures consistent wall thickness and uniform size, allowing high-efficiency continuous production.

Drying

Remove moisture using brick kilns or multi-layer dryers. Egg cartons become strong and stackable, processing 640–960 kg of water per hour.

Inspection and Packaging

Check dimensions and mold quality, then neatly stack and package the cartons to ensure safe transport and efficient delivery.

Can Egg Carton Molds Be Customized?

Yes, Shuliy supports custom egg cartons, including printing your company logo or creating unique shapes. We first provide design drawings for approval, then produce the molds.

- Size and Specifications: Molds can be customized for egg carton capacity (e.g., 6, 10, 12 eggs), egg spacing, tray thickness, and more.

- Special Shapes: Molds for irregular egg cartons or specific eggs such as duck or goose eggs can be made.

- Material Options: Aluminum alloy, plastic, or stainless steel molds can be chosen based on production volume, durability, and demolding needs.

Can One Egg Carton Machine Use Different Molds?

- Standard Design: SL series large egg carton machines use a modular mold structure for quick installation and removal.

- Multiple Sizes: By changing molds, the machine can produce different carton sizes, such as 6, 10, 12 eggs, or custom dimensions.

- Material Options: Molds are usually aluminum alloy, plastic, or stainless steel, chosen based on production volume, durability, and demolding needs.

Notes for Custom Molds

- Provide egg carton dimensions, tray quantity, and thickness requirements in advance.

- Different mold materials vary in wear resistance and lifespan; select according to production volume and drying method.

- Custom molds require a production period but offer long-term use and stable returns.

Why Choose Shuliy?

- High Capacity: SL series egg tray machines produce 4,000–7,000 pcs/hr, ideal for medium to large factories. In addition, we can also produce special-shaped trays, such as shoe tray molding machines, fruit tray molding machines, electronic packaging tray molding machines, and coffee tray molding machines, etc.

- Stable and Durable: Thick carbon steel frame and industrial-grade materials ensure over 10 years of continuous operation.

- Flexible Molds: Supports mold replacement or customization in different sizes and materials to meet diverse market needs.

- Efficient Design: Eight-face rotary molding allows continuous pulp suction, forming, dewatering, and demolding.

- Energy Efficient: Balanced output and power, low energy consumption per carton, with controllable pulp and water use.

- Compatible with Drying Systems: Works with brick kilns or multi-layer dryers for fully automated production lines.

- International Certifications: ISO 9001, CE, SGS, and TUV certified, ensuring quality and export safety.