How to start a paper egg tray making plant?

Recycling waste paper processing paper egg trays is an important and profitable industry. Moreover, the paper egg tray processing business is currently very popular in many African countries. So, how do we start a paper egg tray making plant? And how to make egg trays with the paper pulp processing line?

What is the paper egg tray making plant?

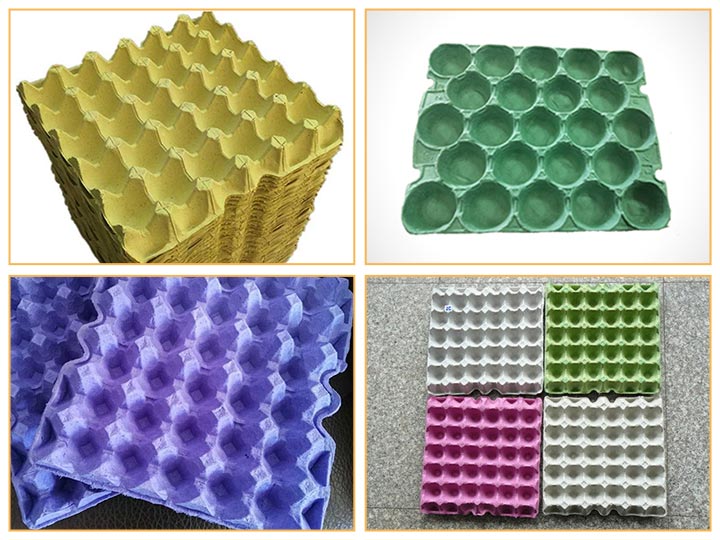

Paper egg tray making plant is usually a complete production line, mainly used for processing various specifications of egg trays, fruit trays, and coffee cup trays, etc. The egg tray processing line is mainly composed of three parts: pulping system, forming system, and drying system.

- Pulp system

Put waste newspapers, cartons, and other raw materials into the pulping machine, add an appropriate amount of water, and then after a long time of stirring, the waste paper will become pulp and put in the pulp storage tank for storage.

Put the pulp in the storage tank into the mixing tank. The pulp concentration is adjusted in the slurry tank, and the thick slurry in the return tank and storage tank is further stirred by a homogenizer, adjusted to a moderate proportion of pulp, and then put into the slurry supply tank for use in the forming system.

The pulping system mainly includes equipment: pulping machine, homogenizer, pulp supply pump, vibrating screen, pulp decomposer.

- Forming system

The evenly stirred pulp in the pulp supply tank is pumped into the forming machine. After being absorbed by the vacuum system, the pulp will remain on the surface of the mold on the equipment and be quickly pressed into shape. The squeezed water will be absorbed by the vacuum pump and flow back into the pool again.

The formed egg tray will be positively pressured out by the transfer mold through an air compressor, and the molded product will be blown from the forming mold to the transfer mold, and some will be sent by the transfer mold.

Commonly used equipment in the egg tray forming stage are: forming machines, molds, vacuum pumps, negative pressure tanks, water pumps, air compressors, mold cleaning machines, etc.

- Drying system

There are many ways to dry egg trays, mainly natural drying, kiln drying, and drying with a dryer. Many African users who bought our egg tray processing line basically choose to dry the egg trays naturally. Users in some countries can choose to buy a multi-layer dryer machine for drying because they do not have better weather conditions.

How to start a paper egg tray making plant?

Starting a small and medium-sized paper egg tray making plant usually requires consulting a professional egg tray machine manufacturer. Because egg tray machine manufacturers can not only provide high-quality egg tray making machines, but also provide detailed egg tray processing solutions.

Generally, in order to save production costs, we will recommend that customers build three tanks for paper pulp making. Then we recommend customers to buy egg tray forming machine and egg trays drying machine. We can also design the processing plant according to the output demand of the customer.