What Is the Manufacturing Process of Pulp Seedling Trays?

To provide an eco-friendly and biodegradable seedling solution, pulp seedling trays are gradually replacing traditional plastic trays, becoming a key choice for green development in modern agriculture. This product is mainly produced from waste paper materials and, through a series of processing steps, is ultimately formed into molded pulp trays suitable for vegetable, rice, and flower seedling cultivation.

Raw Material Pretreatment

Before entering the production stage, waste paper must be shredded and soaked.

After being cut into small pieces by shredding equipment, the waste paper is soaked in clean water for a period of time to fully soften the paper fibers and prepare for the pulping process. The goal of this stage is to turn the waste paper into a pulp form that is easy to disperse.

Pulping

The softened paper material is fed into a pulping machine, where high-speed stirring and shearing further separate the fibers to form a uniform pulp slurry.

When producing pulp seedling trays, the pulp concentration is typically controlled between 5% and 8% to ensure even fiber distribution and a dense structure, laying a solid foundation for high-quality molding.

Filtration and Impurity Removal

To ensure stable equipment operation and product quality, the pulp must pass through an impurity filtration system before molding to thoroughly remove any foreign objects such as plastic pieces, glue residues, or metal staples.

Slurry Formulation

Based on usage scenarios, additives like waterproofing agents, strength enhancers, and biodegradable aids can be added to the pulp. These additives improve moisture resistance, compression strength, and eco-friendliness of the trays.

Types of Pulping Equipment

Traditionally, hydrapulpers are used for pulping. These machines mainly consist of a rotor, motor, and cylindrical tank.

Depending on pulp concentration, hydrapulpers are categorized as:

- High-concentration (~19%) and medium-concentration (~12%) pulpers: Usually operate in batch mode.

- Low-concentration pulpers (~6%): Often used in continuous production lines, offering higher efficiency and are better suited for medium to large-scale tray factories.

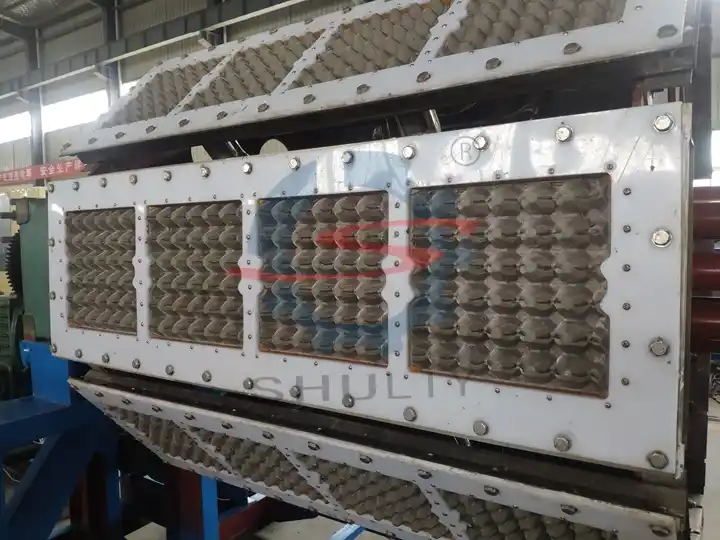

Pulp Seedling Tray Molding and Demolding

In the molding stage, vacuum suction molding technology is typically used.

The mold is submerged in a pulp pool with about 1% slurry concentration. Under vacuum pressure, pulp fibers adhere to the mold surface and gradually accumulate into the desired shape.

Once the preset thickness is reached, a combination of vacuum dewatering and mechanical pressing reduces the moisture content of the wet tray to about 75%–80%. Compressed air is then used to detach the molded tray from the mold, completing the demolding process.

Natural Sun Drying vs. Hot Air Drying

The molded wet trays must be thoroughly dried to enhance structural strength:

- Natural drying: Environmentally friendly and energy-saving but highly weather-dependent, more suitable for small-scale production in regions with stable climates.

- Hot air drying: Ideal for large-scale, continuous production. This often involves using brick drying chambers or metal drying boxes with good insulation.

Hot air temperature is typically maintained between 130°C and 200°C, with air speed around 5 m/s. Proper humidity and airflow control greatly improve drying efficiency and product consistency.

Hot Pressing

Dried seedling trays are then placed in a hot pressing machine, where they are heated and compressed in molds to adjust flatness and density further. This enhances the tray’s compression strength and prolongs service life.

Hot pressing duration depends on the shape and thickness of the product and typically ranges from 30 to 50 seconds. This process not only improves surface consistency but also ensures every tray meets high-quality standards.

Conclusion

As investment in eco-friendly agriculture continues to grow, pulp seedling trays—with advantages such as biodegradability, environmental friendliness, low cost, and broad applicability—are becoming the preferred choice for nurseries growing vegetables, rice, and herbaceous flowers.

Shuliy Machinery offers complete production line solutions, including pulpers, forming machines, hot press machines, and drying equipment. We support custom mold designs with various cavity options (such as 32-cell, 50-cell, and 72-cell), helping customers improve productivity and efficiency.