Welcome Turkish Customers to Visit Our Factory and Learn About the Pulp Egg Tray Making Machine Production Process

On July 14, 2025, we received customers from Turkey. The main purpose of their visit was to inspect our pulp egg tray making machine and the complete egg tray production line. Through the factory tour, equipment demonstration, and technical discussions, the customers highly recognised our production strength, manufacturing process, and technical support. This visit laid a solid foundation for future cooperation between both sides.

Customer Visit Background

Turkey, as an important hub between the Middle East and Europe, has seen rapid growth in the pulp-moulded packaging industry in recent years. The demand for eco-friendly packaging, such as egg trays and fruit trays, continues to rise.

The visiting customer hopes to find a reliable, stable, and cost-effective supplier of egg tray equipment to build a fully automatic egg tray production line suitable for the local market.

After several rounds of communication online, the customer decided to come to China for an on-site visit to learn more about our production capabilities.

Visit to the Pulp Egg Tray Making Machine Workshop

Parts Processing Area

The customer observed processes such as laser cutting, welding, and CNC machining, and was impressed by our strict quality standards.

Molding Machine Assembly Area

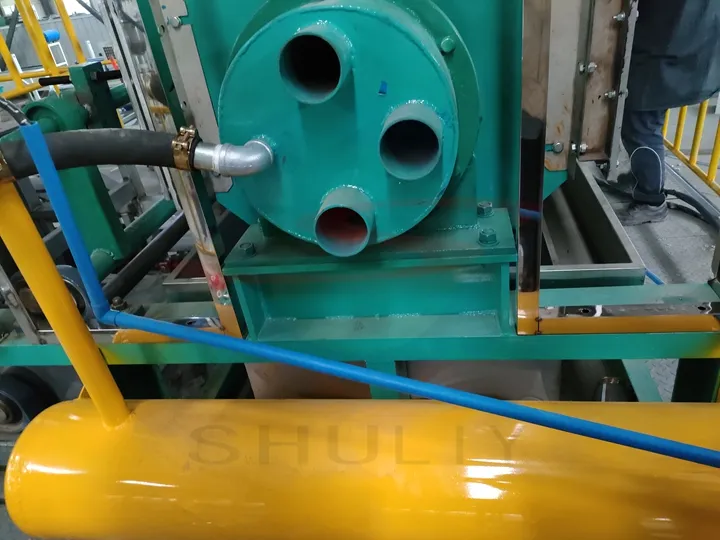

Our engineers demonstrated the core structure of the fully automatic pulp egg tray making machine, including the vacuum system, forming molds, electrical cabinet, and control system.

Drying System Display

We highlighted the multi-layer metal belt drying solution and provided energy-saving design suggestions based on Turkey’s fuel costs. The customer paid special attention to production capacity, mold lifespan, and energy efficiency, and our technical team explained each point in detail.

On-Site Test of the Egg Tray Making Machine

To give the customer a direct understanding of the equipment, we arranged an on-site test run of the pulp egg tray machine.

The customer focused on:

- Forming speed

- Vacuum pump suction and energy consumption

- Uniformity and strength of the egg trays

- Automatic stacking and conveying performance

During the test, the machine ran smoothly, molds flipped without issues, and the finished egg trays were uniform in shape and weight. The customer gave high praise for the performance.

Discussion on Customised Solution for the Turkish Market

After the factory tour, we held a detailed technical discussion with the customer and proposed a production line configuration suitable for the local Turkish market.

Our designed solution includes:

- Fully automatic egg tray production line with 2,500–3,500 pcs/h output

- Multi-layer metal drying line to improve energy efficiency and save space

- Natural gas hot air furnace recommended based on local biomass fuel prices

- Replaceable molds to produce various trays, including egg trays, fruit trays, and cup trays

The customer was very satisfied with this solution and said they will further advance the procurement process after returning home.

Customer Feedback

During the discussion, the customer gave several positive comments about our company:

- Large factory with standardised production processes

- A professional technical team capable of providing customised services

- High-quality core components with reliable delivery times

- Comprehensive after-sales support, including installation, commissioning, and operator training

Parameter Display

| Model | Capacity | Power | Voltage | Weight | Pulp Usage | Water Usage | Size(mm) |

| SL-1000-3X1 | 1000pcs/h | 38kw | 380V,50HZ | 2500kg | 80kg/h | 160kg/h | 2600*2200*1900 |

| SL-1500-4X1 | 1500pcs/h | 38kw | 380V,50HZ | 3000kg | 120kg/h | 240kg/h | 2800*2200*1900 |

| SL-2500-3X4 | 2500pcs/h | 55kw | 380V,50HZ | 4000kg | 200kg/h | 400kg/h | 2900*1800*1800 |

| SL-3000-4X4 | 3000pcs/h | 60kw | 380V,50HZ | 4800kg | 240kg/h | 480kg/h | 3250*1800*1800 |

| SL-4000-4X8 | 4000pcs/h | 95kw | 380V,50HZ | 7000kg | 320kg/h | 640kg/h | 3250*2300*2500 |

| SL-5000-5X8 | 5000pcs/h | 95kw | 380V,50HZ | 8000kg | 400kg/h | 800kg/h | 3700*2300*2500 |

| SL-7000-6X8 | 7000pcs/h | 120kw | 380V,50HZ | 10000kg | 480kg/h | 960kg/h | 3200*2300*2500 |

Looking Forward to Future Cooperation

The visit from the Turkish customer not only gave them a direct understanding of our technical strength but also further strengthened mutual trust. In the future, we will continue to provide high-performance equipment and comprehensive services to help them expand in Turkey’s eco-friendly pulp-moulded packaging market.

We believe that, with joint efforts, this visit marks the beginning of future cooperation. We also welcome customers from around the world to visit our factory and look forward to working with you.