Seedling Tray Making Machine

| Brand | Shuliy Machinery |

| Model | SL Series |

| Capacity | 1000-7000pcs/h |

| Power | 38-120kw |

| Voltage | 380V,50HZ |

| Size | Reference Technical Parameter Table |

| Warranty | 12 Months |

You can now ask our project managers for technical details

A seedling tray making machine is an essential agricultural machine that uses waste paper pulp or plant fibers to produce high-quality seedling trays. Through a special pulp molding process, the machine shapes the material into durable and eco-friendly trays, perfect for various seedling applications.

This seedling tray making machine is widely used in large-scale farms, small nurseries, and factory seedling production. It is ideal for growing vegetables, flowers, rice, tobacco, fruit trees, landscaping plants, lawns, and more.

The trays made by the machine are 100% biodegradable, non-polluting, and rich in organic matter. After the seedlings grow, the trays can be directly transplanted into the soil along with the plants. This not only saves time by avoiding cleaning and recycling but also acts as an organic fertilizer to improve soil quality.

Shuliy offers a seedling tray machine in different models with capacities from 1,000 to 7,000 pieces per hour. We also provide custom mold design and complete seedling tray production line solutions to help you increase production efficiency and reduce costs.

If you are looking for a reliable seedling tray making machine manufacturer, Shuliy can provide high-quality machines and professional support for your seedling tray business.

Features of Shuliy Seedling Tray Making Machine

Eco-friendly and biodegradable

Made from safe, non-polluting materials that naturally decompose, reducing environmental impact.

Wide range of raw materials

Can use various easily available materials such as waste paper, cardboard, wood pulp, as well as agricultural wastes like rice husk powder, coconut coir, corn stalk powder, and bamboo powder.

Reduces pests and weeds

Using seedling trays helps effectively lower pest occurrence and suppress weed growth.

Saves fertilizer

Reduces fertilizer use by 20%–50% and decreases the number of fertilizations needed; no fertilization is required in later stages.

High survival rate

Rich in nutrients, it causes no root damage during transplanting, with survival rates close to 100%.

Uniform seedling emergence

Guarantees consistent growth of seedlings, improving crop quality.

Speeds up maturity

No re-greening period, allowing crops to mature 15–30 days earlier.

Strong compatibility

Compatible with various manual and automatic seeders.

Application of the Seedling Tray Making Machine

The seedling tray machine is widely used in agricultural seedling production, suitable for various crops such as flowers, rice, tobacco, and vegetables.

Application Range

- Vegetables: Tomato, chili, cucumber, eggplant, melon, cabbage, lettuce, and more.

- Flowers: Rose, carnation, chrysanthemum, succulent plants, and other flower seedlings.

- Rice: Indica rice, japonica rice, glutinous rice, etc.

- Tobacco: Flue-cured tobacco, air-cured tobacco, sun-cured tobacco, oriental tobacco, and others.

Advantages

- Wide applicability: Suitable for greenhouse seedling production, open-field seedling, and vertical seedling methods.

- Strong compatibility: Compatible with manual, semi-automatic, and fully automatic seeders, facilitating mechanized production.

- Cost-saving: Saves seeds, reduces fertilizer use by 20%–50%, lowers labor costs by 30%–60%, and decreases pesticide use.

- Eco-friendly and sustainable: Produces environmentally safe seedling trays that do not pollute soil or the environment; some trays are biodegradable.

- Improves seedling quality: Provides a stable nutrient environment for seeds, and causes no root damage during transplanting with survival rates close to 100%.

Technical Parameters of Nursery Tray Forming Machine

| Model | Capacity | Power | Voltage | Weight | Pulp Usage | Water Usage | Size(mm) |

| SL-1000-3X1 | 1000pcs/h | 38kw | 380V,50HZ | 2500kg | 80kg/h | 160kg/h | 2600*2200*1900 |

| SL-1500-4X1 | 1500pcs/h | 38kw | 380V,50HZ | 3000kg | 120kg/h | 240kg/h | 2800*2200*1900 |

| SL-2500-3X4 | 2500pcs/h | 55kw | 380V,50HZ | 4000kg | 200kg/h | 400kg/h | 2900*1800*1800 |

| SL-3000-4X4 | 3000pcs/h | 60kw | 380V,50HZ | 4800kg | 240kg/h | 480kg/h | 3250*1800*1800 |

| SL-4000-4X8 | 4000pcs/h | 95kw | 380V,50HZ | 7000kg | 320kg/h | 640kg/h | 3250*2300*2500 |

| SL-5000-5X8 | 5000pcs/h | 95kw | 380V,50HZ | 8000kg | 400kg/h | 800kg/h | 3700*2300*2500 |

| SL-7000-6X8 | 7000pcs/h | 120kw | 380V,50HZ | 10000kg | 480kg/h | 960kg/h | 3200*2300*2500 |

Shuliy offers various models of nursery tray forming machines and can customize molds according to your requirements. Welcome to contact us for more information.

What is the Working Principle of the Seedling Tray Making machine?

The seedling tray machine works by mixing waste paper pulp or plant fibers with water to form a uniform slurry. This slurry is then vacuum-pressed onto the surface of a mold to shape the tray. Excess water is removed through a pressing and filtering process.

Finally, the formed trays are dried and solidified using hot air or steam, producing eco-friendly, biodegradable seedling trays ready for direct use in seedling cultivation.

Main Structural Components

Pulping System (hopper, pulper, pipelines) — Responsible for delivering the prepared pulp slurry to the forming molds.

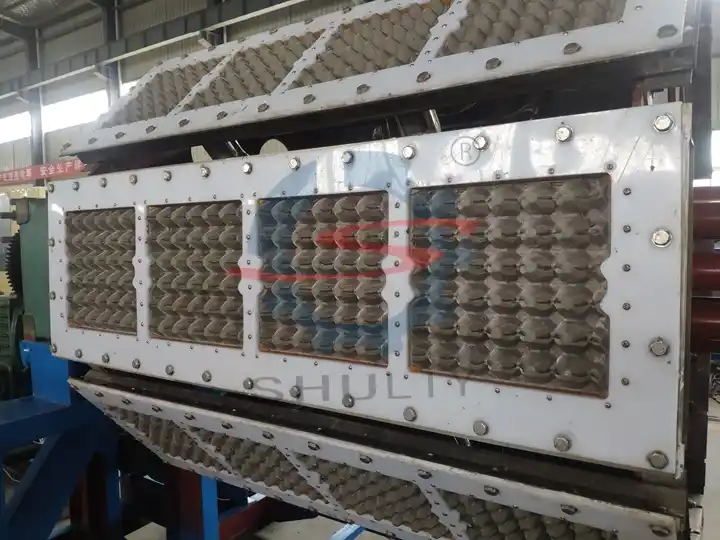

Forming System (molds, vacuum suction device) — Uses vacuum suction to attach the pulp slurry onto the mold surface, shaping it into trays.

Pressing and Filtering System — Removes excess water from the formed trays, increasing product density and strength.

Drying System (belt dryer or drying room) — Quickly dries the wet trays to the required moisture content.

Vacuum System (vacuum pump, water tank) — Provides the negative pressure environment needed for vacuum molding.

Control System (PLC control cabinet) — Centrally controls the operation of the entire machine.

Production Process of Seedling Tray Machine

Raw material preparation → Crushing → Pulping → Forming → Pressing and filtering → Drying → Finished product inspection → Packaging and shipment

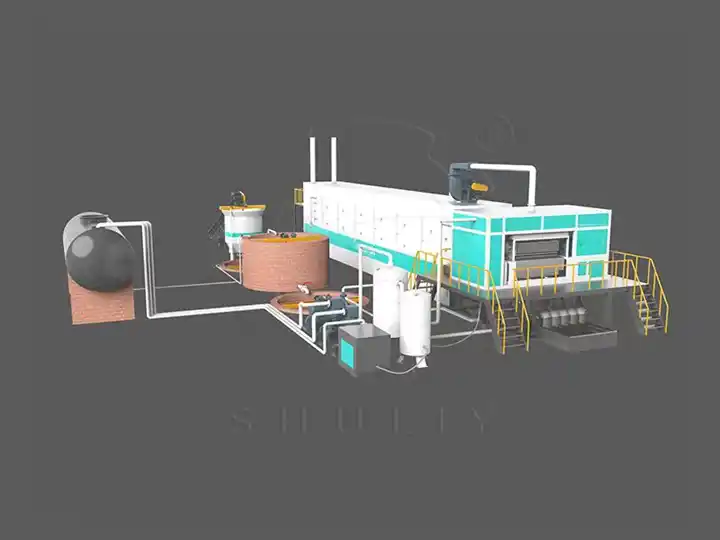

Seedling Tray Production Line Process

The production line achieves efficient continuous manufacturing of seedling trays through raw material pulping, vacuum molding, pressing and dehydration, drying and curing, cooling and inspection, and automatic packaging.

- Raw Material Preprocessing — Crush and screen raw materials like straw, waste paper, and plant fibers to ensure the slurry is uniform and fine.

- Pulping System — Fully mix the raw materials with water using a pulper to create a suitable pulp slurry for forming.

- Forming System — Use vacuum suction molds to form the pulp into the shape of seedling trays evenly.

- Pressing and Filtering System — Press the formed seedling trays to remove excess water and increase their strength.

- Drying System — Dry the wet seedling trays using a belt dryer or box dryer.

- Cooling and Inspection — Cool the dried products and perform quality checks to ensure no damage and correct dimensions.

- Automatic Packaging System — Automatically count, stack, and package qualified seedling trays for easy storage and transportation.

Flowchart

Waste paper → Pulping → Forming → Drying → Hot Pressing → Packing

Features of the Production Line

- High automation level, saving labor costs.

- High production efficiency, meeting large-scale demand.

- Eco-friendly products; seedling trays are biodegradable and comply with green agriculture standards.

- Adjustable specifications based on requirements (e.g., 32-cell, 50-cell, 72-cell seedling.

Why Use Pulp Seedling Trays?

Plastic Seedling Trays VS Pulp Seedling Trays

Plastic Seedling Trays

- Environmental Impact: Not easy to degrade, may cause pollution.

- Breathability: Poor air permeability affects root respiration.

- Nutrient Release: No nutrients, serves only as a container.

- Convenience: Sturdy structure, suitable for repeated use.

- Cost: Low initial purchase cost but higher cleaning and maintenance costs over time.

- Durability: Strong, pressure, and impact resistant.

- Seedling Effect: Good for repeated use, but poor breathability and drainage may affect seedling health.

Pulp Seedling Trays

- Environmental Impact: Biodegradable; can be transplanted directly with seedlings, reducing pollution.

- Breathability: Good air permeability promotes healthy root growth.

- Nutrient Release: Contains organic matter and trace elements, gradually releasing nutrients to support seedling growth.

- Convenience: Lightweight, disposable; no cleaning or recycling needed after use.

- Cost: Low raw material cost and simple production process, offering high cost-effectiveness.

- Durability: Relatively lower strength, easily broken, not suitable for repeated use.

- Seedling Effect: Helps root development and improves survival rate and seedling quality.

Classification of Seedling Trays

By Cell Number

- Small-Cell Seedling Trays: Have many cells, such as 72-cell or 104-cell trays, suitable for planting small seeds like flowers and herbaceous plants.

- Medium-Cell Seedling Trays: Common sizes include 32-cell and 50-cell trays, ideal for vegetables and fruits with medium-sized seeds.

- Large-Cell Seedling Trays: Have fewer cells, such as 24-cell or 18-cell trays, suitable for large seeds or crops that need more root space, like tomatoes and chili peppers.

By Shape

- Square Seedling Trays

- Round Seedling Trays

- Seedling Trays with Bottom Trays

- Pulp Seedling Trays with Drainage Holes

Popular Seedling Tray Machines for Sale

Fully Automatic Pulp Seedling Tray Machine

- Capacity: 4,000–5,000 pieces/hour, suitable for large-scale seedling farms.

Semi-Automatic Seedling Tray Machine

- Capacity: 1,000–3,000 pieces/hour, ideal for small to medium businesses; easy to operate with lower investment cost.

Multi-Specification Switchable Seedling Tray Machine

- Allows quick switching between different mold specifications to meet diverse production needs.

Welcome to contact us for any inquiries or more information.