Pulp Wine Trays VS Foam Inserts: Which Is the Best Choice for Wine Packaging?

In wine packaging, pulp wine trays and foam (EPS) inserts are commonly used to protect glass bottles during transport. Traditionally, foam inserts are widely used, but with stricter environmental regulations, pulp wine trays are quickly replacing foam packaging.

So, which is the best choice for wine packaging? Let’s compare them in terms of environmental friendliness, protection, cost, and storage & transportation efficiency.

Environmental Performance Comparison

Pulp Wine Trays

- Material: 100% recycled paper pulp or plant fiber

- Biodegradable: Breaks down in about 90 days in natural conditions

- Recycling Rate: > 80%

Foam Inserts

- Material: Petrochemical product (EPS)

- Biodegradable: Over 200 years

- Recycling Rate: < 10%, with high recycling costs

Cushioning and Compression Performance

Pulp Wine Trays

- Compression Strength: 20–25 kg

- Shock Resistance: ≥ 80% (bottle intact rate in drop tests)

Foam Inserts

- Compression Strength: 15–18 kg

- Shock Resistance: ~70%

Cost Comparison (Per Wine Tray)

Pulp Wine Trays

- Material: Waste paper, about $0.02 each

- Energy: About $0.01 each

- Total Cost: ≈ $0.04 each

Foam Inserts

- Material: EPS pellets, about $0.05 each

- Energy: ≈ $0.01 each

- Total Cost: ≈ $0.06 each

Storage & Transport Efficiency

- Pulp Wine Trays: Stackable, saves about 40% storage space

- Foam Inserts: Not compressible, bulky, takes more space

Overall Benefits

- Pulp Wine Trays: Eco-friendly, lower cost, better protection

- Foam Inserts: Being phased out; some countries have banned

Pulp Wine Trays vs Foam Inserts

| Category | Pulp Wine Tray | Foam Insert (EPS) | Advantage |

|---|---|---|---|

| Eco-friendliness | Material: Waste paper/ plant fibers Biodegradable: ≈90 days Recycling rate: >80% | Material: Petrochemical EPS Decomposition time: ≈ 200 years Recycling rate: <10% | Pulp Wine Tray |

| Compression Strength | 20–25 kg | 15–18 kg | Pulp Wine Tray |

| Shock Resistance | ≥80% (bottle intact rate in drop test) | ≈70% | Pulp Wine Tray |

| Unit Cost | ≈$0.04/pc (Raw material $0.02 + Energy $0.01 + Labor /Maintenance $0.01) | ≈$0.06/pc (Raw material $0.05 + Energy $0.01) | Pulp Wine Tray (30% lower) |

| Storage & Transport | Stackable, saves about 40% space | Non-compressible, bulky | Pulp Wine Tray |

| Compliance | Meets global plastic ban trends; well accepted in EU & US markets | Banned in many countries; export restricted | Pulp Wine Tray |

| Applications | Red wine, white wine, beer, spirits, craft beer multipacks | Mainly low-end local packaging | Pulp Wine Tray |

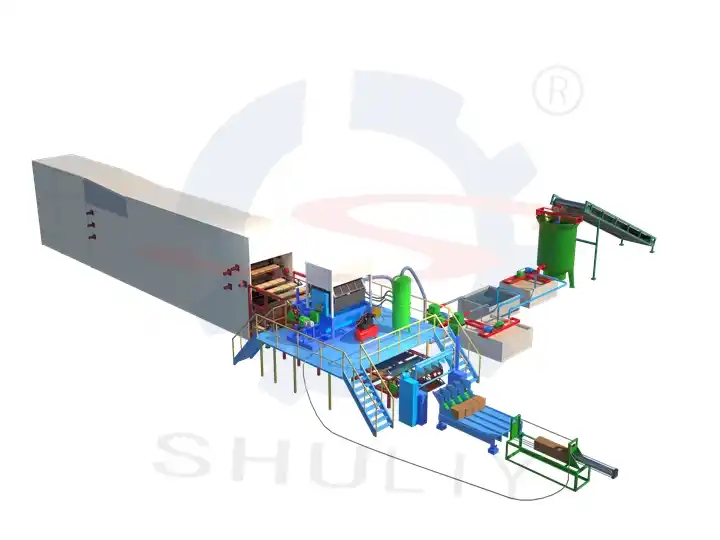

Recommended Wine Tray Production Line Models

Shuliy offers a range of machines for producing pulp wine trays and can provide customized solutions based on your requirements. If you’re interested, leave a message via the website chat popup, and we will contact you within 24 hours.

| Model | Capacity | Power | Voltage | Weight | Pulp Usage | Water Usage | Size(mm) |

| SL-1000-3X1 | 1000pcs/h | 38kw | 380V,50HZ | 2500kg | 80kg/h | 160kg/h | 2600*2200*1900 |

| SL-1500-4X1 | 1500pcs/h | 38kw | 380V,50HZ | 3000kg | 120kg/h | 240kg/h | 2800*2200*1900 |

| SL-2500-3X4 | 2500pcs/h | 55kw | 380V,50HZ | 4000kg | 200kg/h | 400kg/h | 2900*1800*1800 |

| SL-3000-4X4 | 3000pcs/h | 60kw | 380V,50HZ | 4800kg | 240kg/h | 480kg/h | 3250*1800*1800 |

| SL-4000-4X8 | 4000pcs/h | 95kw | 380V,50HZ | 7000kg | 320kg/h | 640kg/h | 3250*2300*2500 |

| SL-5000-5X8 | 5000pcs/h | 95kw | 380V,50HZ | 8000kg | 400kg/h | 800kg/h | 3700*2300*2500 |

| SL-7000-6X8 | 7000pcs/h | 120kw | 380V,50HZ | 10000kg | 480kg/h | 960kg/h | 3200*2300*2500 |