Pulp Bedpan Making Machine

| Brand | Shuliy Machinery |

| Model | SL Series |

| Capacity | 1000-7000pcs/h |

| Power | 38-120kw |

| Voltage | 380V,50HZ |

| Size | Reference Technical Parameter Table |

| Warranty | 12 Months |

You can now ask our project managers for technical details

The pulp bedpan making machine uses pulp molding technology to produce disposable bedpans, commonly used in hospitals, nursing homes, and care facilities.

Disposable bedpans are made from waste paper, wood pulp, bagasse, bamboo pulp, grass pulp, and recycled cardboard or paper boxes. They are low-cost, clean, easy to handle, and biodegradable, making them environmentally friendly.

Bedpans produced by Shuliy machines have a tight structure and can support 1–1.5 kg of waste. They can hold liquids for 4–6 hours without leaking or collapsing.

This machine has a production capacity of 1,000–7,000 pcs/hour and can be integrated into a full bedpan production line. If you are interested in this business, you can consult Shuliy for a production plan. We can provide bedpans in the size and shape you need.

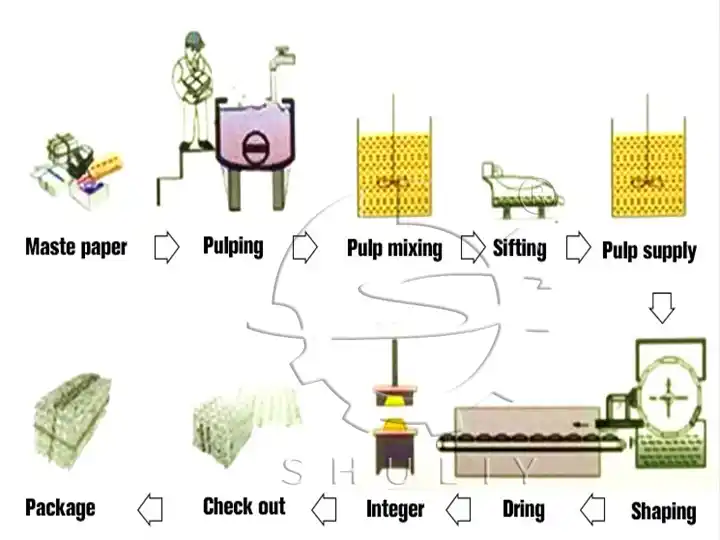

Working Principle of the Disposable Bedpan Making Machine

The disposable bedpan making machine first processes waste paper or cardboard through a pulping system to create a uniform pulp slurry. The slurry is then formed on molds by vacuum suction and pressing, producing wet bedpan blanks.

Next, the machine automatically demolds the blanks and removes moisture through a drying system. Finally, the bedpans undergo hot pressing and trimming to achieve the standard size and smooth surfaces, resulting in finished disposable bedpans.

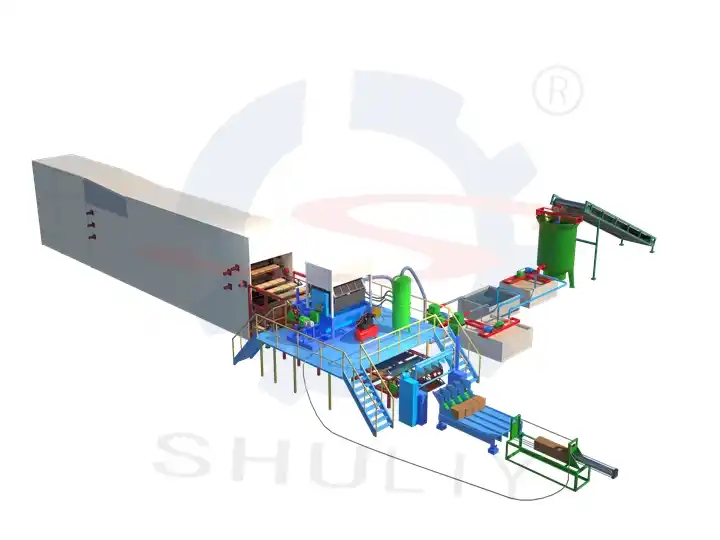

Main Structure of Disposable Bedpan Forming Machine

The disposable bedpan forming machine mainly consists of a pulping system, forming system, vacuum suction system, electrical control system, and molds.

Machine Features

- High automation, capable of continuous production at 1,000–7,000 pcs/hour

- Uses pulp as raw material; biodegradable and environmentally friendly

- Disposable, preventing cross-infection

- Interchangeable molds for producing different sizes of disposable care products (e.g., urinal trays, nursing bedpans)

- Made entirely of high-quality steel for long-lasting use

- PLC-controlled and easy to operate

- Can be paired with a dryer to form a complete production line

- High forming precision, with product size deviation within ±1 mm and uniform thickness

Application Industries

- Hospitals, clinics, and rehabilitation centers

- Elderly care facilities and nursing homes

- Home care and short-term care centers

- Emergency and temporary medical facilities

Target Users

- Bedridden patients, elderly, pregnant and postpartum women, people with disabilities

- Patients in hospitals and care institutions

- People with emergency or temporary needs

Machine Specifications of Pulp Bedpan Making Machine

| Model | Capacity | Power | Voltage | Weight | Pulp Usage | Water Usage | Size(mm) |

| SL-1000-3X1 | 1000pcs/h | 38kw | 380V,50HZ | 2500kg | 80kg/h | 160kg/h | 2600*2200*1900 |

| SL-1500-4X1 | 1500pcs/h | 38kw | 380V,50HZ | 3000kg | 120kg/h | 240kg/h | 2800*2200*1900 |

| SL-2500-3X4 | 2500pcs/h | 55kw | 380V,50HZ | 4000kg | 200kg/h | 400kg/h | 2900*1800*1800 |

| SL-3000-4X4 | 3000pcs/h | 60kw | 380V,50HZ | 4800kg | 240kg/h | 480kg/h | 3250*1800*1800 |

| SL-4000-4X8 | 4000pcs/h | 95kw | 380V,50HZ | 7000kg | 320kg/h | 640kg/h | 3250*2300*2500 |

| SL-5000-5X8 | 5000pcs/h | 95kw | 380V,50HZ | 8000kg | 400kg/h | 800kg/h | 3700*2300*2500 |

| SL-7000-6X8 | 7000pcs/h | 120kw | 380V,50HZ | 10000kg | 480kg/h | 960kg/h | 3200*2300*2500 |

The above are our standard models. For additional requirements, please contact us.

Disposable Bedpan Production Line

The disposable bedpan production line uses waste paper or cardboard as raw material. Through pulping, forming, drying, and shaping processes, it mass-produces eco-friendly disposable pulp bedpans.

The production line typically includes a pulping system, forming system, drying system, and automatic control system.

Features of Best-Selling Disposable Bedpans

- Sturdy and Durable: Made from high-density pulp, tightly structured, resistant to deformation, and can support 1–1.5 kg

- Liquid-Resistant: Can hold liquids (e.g., urine, disinfectant) for 4–6 hours without leaking or collapsing

- Hygienic and Safe: Meets medical hygiene standards; widely used in hospitals, nursing homes, and care centers

- Eco-Friendly and Biodegradable: Naturally decomposes after use or can be disposed of as combustible waste, causing no secondary pollution

- Lightweight and Comfortable: Ergonomic design with smooth edges; easy to handle and operate for caregivers

- Highly Compatible: Can be used with disposable care trays, urinal trays, and other related products

- Shelf Life: Can be stored 1–2 years in a dry environment

Why Hospitals Are Using Disposable Bedpans?

- With the improvement of healthcare standards, more hospitals are replacing traditional plastic or metal bedpans with disposable pulp bedpans.

- Prevent Cross-Infection: Traditional bedpans require cleaning and disinfection, but bacterial residue and cross-infection risks remain.

- Save Labor and Time: Disposable bedpans significantly reduce nursing workload and improve efficiency.

- Improve Patient Comfort: Lightweight and smooth-edged pulp bedpans are especially friendly for bedridden patients and the elderly.

- Environmentally Friendly and Compliant: Made from biodegradable materials; can be incinerated or naturally decomposed without long-term medical waste pollution, meeting modern medical waste and environmental regulations.

- Convenient for Emergency and Large-Scale Use: Ideal for rapid, large-scale deployment during pandemics, disaster relief, or mass medical treatment.

Why Choose Shuliy?

- Advanced Technology: Uses hot-press forming technology to efficiently and stably produce bedpans in various sizes and shapes.

- Durable Materials: Machine frame made of Q345 carbon steel – strong, weldable, and cost-effective.

- High-Quality Molds: Molds available in 45# steel or aluminum (aluminum is more affordable).

- Reliable Transmission: Key moving parts made of high-strength 40Cr steel for long-term stable operation.

- Corrosion-Resistant Components: Feeding chute and pulp outlet generally made of SS304 stainless steel.

- Full Overseas Support: Includes installation, full video tutorials, and technical assistance.

- Experience and Recognition: Over 10 years of R&D experience, supported by the government and hospitals.

- Certifications: TUV, SGS, CE, ISO9001

- Warranty: 12 months

- Customizable: Power supply, voltage, plugs, and molds can be customized.

- Versatile Production: Can also produce complementary items such as emesis basins, patient pans, and urinals.

If you are interested in our machines, please contact us through the pop-up window for consultation.