Electronic Component Pulp Tray Forming Machine

Electronic component pulp tray forming machines are often used to make pulp packaging for electronic components. However, many electronic components are packed with plastic trays. Which components are more suitable for paper-based packaging? How does an electronic component pulp tray forming machine make paper packaging?

What is an electronic component pulp tray forming machine?

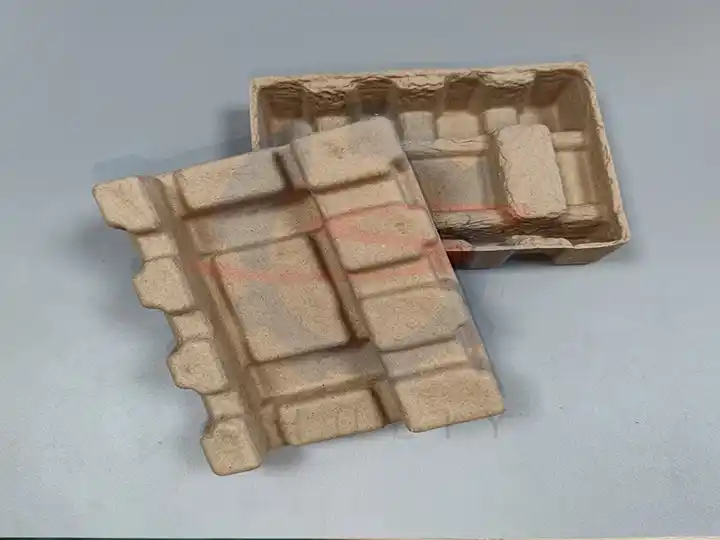

An electronic component pulp tray forming machine is a reciprocating molding device used to make trays for electronic components. It usually uses pulp molding technology to shape raw materials into trays suitable for storing electronic parts. These trays are anti-static, impact-resistant, and eco-friendly, making them ideal for transporting and storing precision electronic components.

Which electronic components are more suitable for paper-based packaging?

- Integrated circuits (ICs) and chips: Small chips, BGA (Ball Grid Array), QFN, and similar components.

- Diodes, transistors: Small semiconductor components, especially in low- to medium-static-sensitive environments. Pulp trays provide effective isolation and protection.

- Capacitors and resistors: Small SMD (surface-mount) components. Pulp trays help prevent scattering.

- Connectors and pins: Small to medium connectors and pin headers. Custom molds can fix the component positions, making assembly easier.

- Electronic modules: Small pre-packaged modules, such as sensor modules, LED modules, and relay modules.

Pulp trays are best for components that are low- to medium-static-sensitive, need impact resistance, and require eco-friendly packaging. Custom tray holes and structures can be designed to fit different types of parts.

Precautions

- Components with high anti-static requirements (e.g., sensitive CMOS chips, high-frequency ICs) may need an anti-static coating on the pulp tray surface or use special anti-static plastic trays.

- Very moisture-sensitive or high-precision components, such as certain MEMS sensors or optical parts, may not be suitable for regular pulp trays and may require moisture-proof bags or desiccants.

Working principle of an electronic component pulp tray forming machine

Like ordinary pulp-molded products, the process starts with making pulp, then forming it with the machine, followed by drying and hot pressing to produce the electronic component trays. The main difference is that this machine uses a reciprocating molding method, while many ordinary pulp-molded products use a drum-type forming process.

Process of making electronic component pulp trays

- Pulping: Waste paper is pulped using a hydraulic method. The pulp concentration can be controlled, and the pulp remains uniform.

- Reciprocating forming: The mold moves back and forth in the pulp slurry. Vacuum suction makes the pulp fibers stick evenly to the mold surface, forming a wet tray blank.

- Drying: Trays can air-dry or be dried in a drying room. For higher efficiency, a multi-layer belt metal dryer can be used for fully automatic processing.

- Hot pressing: Some trays may have small wrinkles after forming. For smooth surfaces and precise dimensions, trays are hot-pressed again.

- Packaging: Trays can be stacked and packed using a packing machine to improve efficiency.

Model recommendation

| Model | SL-R2000 |

| Capacity | 1000-2000pcs/h |

| Power | 55kw |

| Voltage | 380V,50HZ |

| Pulp Usage | 200kg/h |

| Water Usage | 400kg/h |

| Size(mm) | 2900*1800*1800 |

The above are our standard models. We can also customize them according to your requirements, such as power voltage, plug type, molds, and more.

Features of the SL-R2000 electronic component pulp tray making machine

- High capacity: Produces 1,000–2,000 trays per hour, suitable for medium to large electronic component production or packaging, enabling efficient operation.

- Powerful motor: Equipped with a 55 kW motor for stable and reliable forming, maintaining high efficiency even during long continuous operation.

- Energy-saving and eco-friendly: Uses 200 kg of pulp and 400 kg of water per hour. High material utilization reduces production cost and meets environmental standards.

- Precise forming: Advanced mold technology ensures uniform tray size and accurate holes, protecting components during storage and transport.

- Compatible power supply: Designed for 380 V, 50 Hz, suitable for most industrial facilities and easy to install.

- Compact design: Dimensions of 2900×1800×1800 mm; small footprint makes it easy to integrate into production lines.

- Reliable and stable: Fully automatic operation reduces manual intervention, lowers failure risk, and improves production safety.

Services and Support Provided by Shuliy

Precision manufacturing

Processed and welded using high-precision CNC machines.

Excellent after-sales service

Delivery managers promptly address operational issues and maintain active communication. Machines come with a 1-year warranty.

Professional installation support

Our engineers can be sent on-site for installation, debugging, and trial operation.

Strict quality control

Each machine undergoes electrical testing, mold accuracy checks, trial runs, and operational tests before delivery.

Comprehensive solutions

From pre-sale consultation and 3D design to full-process delivery, we provide one-stop service and support.

If you need a professional industrial packaging machine to produce industrial packaging trays, Shuliy’s industrial tray forming machine is your top choice. Our equipment offers high cost performance, helping you achieve business success and a great return on investment.