How to Choose the Right Pulp Fruit Tray Production Line?

Pulp fruit tray production line has become an ideal solution to meet the growing demand for eco-friendly packaging. It is gradually replacing plastic trays and becoming the main packaging choice for fruits such as apples, pears, oranges, and kiwis.

For manufacturers planning to enter this field, choosing the right fruit tray production line is a crucial step toward a successful investment. In the following, we will analyze the key selection points in detail, including production capacity, automation level, mold design, energy consumption, and after-sales service.

Determine Your Production Capacity

Before choosing a machine, it’s important to define your daily or hourly output requirements.

Here’s a reference to common models:

| Model | Capacity (pcs/h) | Power | Suitable For |

|---|---|---|---|

| SL-1000-3X1 | 1000 pcs/h | 38 kW | Small workshops or startups |

| SL-2500-3X4 | 2500 pcs/h | 55 kW | Medium-sized packaging factories |

| SL-4000-4X8 | 4000 pcs/h | 75 kW | Large-scale production or export projects |

If your goal is to produce 20,000–30,000 trays per day, the SL-4000 automatic line is recommended for higher efficiency and reduced labor costs.

Choose the Right Automation Level

Currently, there are two main types of pulp fruit tray production lines:

- Semi-automatic line: Requires manual transfer to the drying area; low investment, suitable for small factories.

- Fully automatic line: Includes automatic forming, drying, and stacking; higher efficiency, lower labor cost, ideal for mass production.

If your budget allows and you have large orders, the fully automatic line will be more cost-effective in the long run.

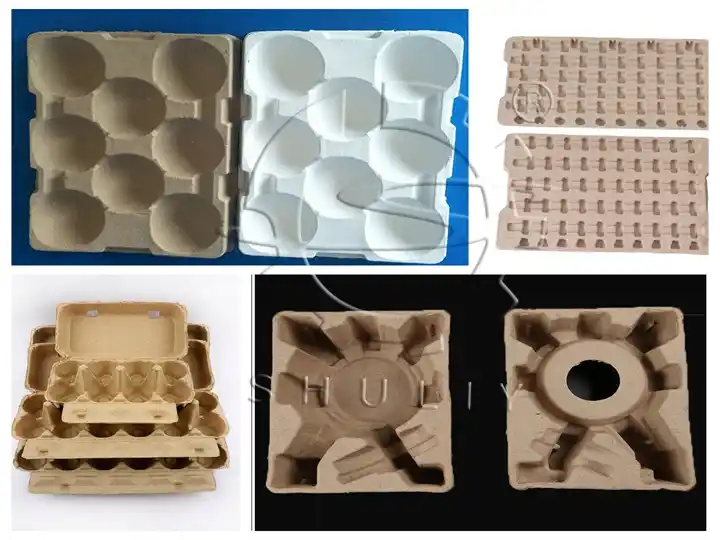

Focus on Mold Design and Tray Quality

Molds determine the shape, size, and strength of the fruit trays.

- Aluminum molds ensure smooth surfaces and precise dimensions.

- Proper air vents and suction holes help achieve uniform pulp distribution.

- Molds can be customized for different fruits such as apples, oranges, or kiwis.

High-quality molds not only improve tray appearance but also extend service life.

Consider Energy Efficiency

Energy consumption directly affects your production cost.

- Choose machines with a heat recycling system to improve drying efficiency.

- Stainless steel inner chambers help retain heat and extend durability.

- Depending on your energy resources, gas or steam heating systems may offer lower running costs.

Evaluate Manufacturer Service and Support

A reliable manufacturer is just as important as a good machine.

An experienced supplier should provide:

- Installation and commissioning guidance (onsite or online)

- One-year warranty and lifelong technical support

- Spare parts and operator training

Shuliy Machinery provides complete fruit tray production solutions and has exported equipment to Chile, Mexico, and Egypt, earning excellent customer feedback.

Related Machine Recommendations

| Model | Capacity | Power | Voltage | Weight | Pulp Usage | Water Usage | Size(mm) |

| SL-1000-3X1 | 1000pcs/h | 38kw | 380V,50HZ | 2500kg | 80kg/h | 160kg/h | 2600*2200*1900 |

| SL-1500-4X1 | 1500pcs/h | 38kw | 380V,50HZ | 3000kg | 120kg/h | 240kg/h | 2800*2200*1900 |

| SL-2500-3X4 | 2500pcs/h | 55kw | 380V,50HZ | 4000kg | 200kg/h | 400kg/h | 2900*1800*1800 |

| SL-3000-4X4 | 3000pcs/h | 60kw | 380V,50HZ | 4800kg | 240kg/h | 480kg/h | 3250*1800*1800 |

| SL-4000-4X8 | 4000pcs/h | 95kw | 380V,50HZ | 7000kg | 320kg/h | 640kg/h | 3250*2300*2500 |

| SL-5000-5X8 | 5000pcs/h | 95kw | 380V,50HZ | 8000kg | 400kg/h | 800kg/h | 3700*2300*2500 |

| SL-7000-6X8 | 7000pcs/h | 120kw | 380V,50HZ | 10000kg | 480kg/h | 960kg/h | 3200*2300*2500 |

Choosing the right fruit tray production line requires a comprehensive evaluation of production capacity, automation level, mold quality, energy consumption, and after-sales service.

Only a solution that matches your production scale and market demand can help you achieve higher profits and stronger competitiveness in the eco-friendly packaging industry.

If you are interested in our fruit tray production line, please leave a message through the pop-up window on the right — we will contact you within 24 hours.