Why More Poultry Farms Are Making Their Own Pulp Egg Trays?

In recent years, a clear trend has emerged in the poultry industry: more and more farms are choosing to produce their own pulp egg trays instead of relying entirely on purchased ones. With feed and labor costs becoming more transparent, the profit margin for eggs has been steadily squeezed, while the price of egg trays rises year by year.

Any shortage in egg tray supply directly affects packaging, turnover, and shipping efficiency, having a noticeable impact on farm operations. Producing trays in-house gives farms full control, allowing flexible scheduling based on daily egg production rather than being dependent on suppliers.

Why Poultry Farms Are Obsessed with Making Their Own Pulp Egg Trays?

More and more poultry farms are choosing to produce their own pulp egg trays. The main reasons are cost savings, stable supply, quality control, environmental benefits, and added value.

Lower Costs

- Buying trays involves high procurement and transport costs. Making them in-house allows farms to use low-cost raw materials like waste paper or straw, reducing long-term expenses.

Stable Supply

- Egg trays are a high-frequency consumable. Relying on suppliers can lead to shortages during peak seasons or logistics delays. Producing in-house ensures a steady supply at the farm’s own pace.

Better Match for Egg Needs

- In-house trays can be customized in size and strength to fit different egg sizes and transport methods, reducing breakage.

Environmental and Recycling Benefits

- Using recycled materials aligns with environmental policies and the circular economy, helping to minimize resource waste.

Extend the Value Chain

- Custom tray sizes or branded printing allow farms to integrate “farming—packaging—sales,” increasing market competitiveness.

Consider Practicality

- In-house production is more suitable for larger farms with stable output. Small-scale farmers should carefully evaluate equipment investment and payback time.

Limitations of Standardized Egg Trays

Most commercial egg trays are made with uniform molds and fixed specifications. In practice, however, each poultry farm has different conditions:

- Egg sizes vary between farms

- Sales channels have different strength requirements for trays

- Transport distances and stacking methods differ

As a result, purchased trays often face issues:

- Egg compartments are too loose or too tight

- Higher breakage rates during transport

- Deformation when stacked in multiple layers

In contrast, farms producing their own egg trays can adjust the size, depth, and thickness to match egg dimensions and transport needs. This ensures a better fit, providing more effective protection for eggs.

How Poultry Farms Can Increase Brand Value Through Egg Trays?

With eggs becoming increasingly similar in the market, egg trays are no longer just packaging—they are part of brand presentation.

- Enhance Brand Recognition: Printing the farm’s name or logo on trays helps build consistent recognition throughout the supply chain.

- Show Professionalism and Reliability: Uniform and high-quality trays convey a well-managed farm and stable supply.

- Improve Retail Display: Custom-fit trays reduce breakage and present eggs neatly, enhancing perceived value.

- Highlight Environmental Advantages: Using recycled pulp or agricultural waste trays reinforces a green and sustainable brand image.

Can Extra Pulp Egg Cartons Be Sold?

Yes. In-house production not only meets a farm’s own needs but can also become a side business. For medium to large farms, selling extra trays can reduce overall costs while generating additional income. Quality, specifications, and cost control are key to making this profitable.

How to Find the Right Egg Tray Production Solution for Your Farm?

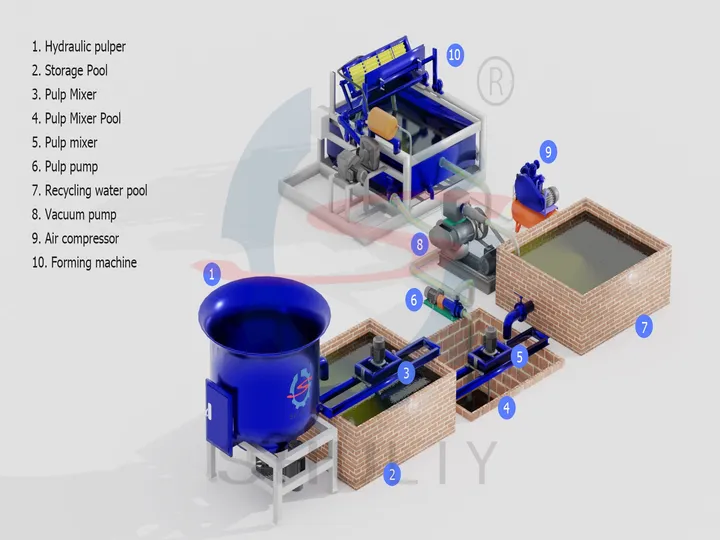

If your farm has a stable daily output or easy access to waste paper, investing in a small egg tray making machine can be a good option. Shuliy offers solutions tailored for small-scale farms. A small tray machine produces 1,000–1,500 trays per hour, keeping initial investment low. Shuliy also provides the most suitable equipment configuration, ensuring you can buy with confidence and operate with ease.

Technical Specifications of Small Egg Tray Making Machines

| Comparison Item | SL-3*1 | SL-4*1 |

|---|---|---|

| Mold Positions | 3 | 4 |

| Output | 1,000 trays/hour | 1,500 trays/hour |

| Total Power | 38 kW | 38 kW |

| Main Machine Weight | 2,500 kg | 3,000 kg (more stable) |

| Paper Consumption | 80 kg/hour | 120 kg/hour |

| Water Consumption | 160 kg/hour | 240 kg/hour |

| Drying Configuration | Air drying / Drying box | Air drying / Drying room (for higher output) |

| Suitable For | Small farms / Startups | Small to medium egg tray factories / Capacity expansion |

If you are interested in investing in egg tray production, feel free to contact us for consultation.

Advantages of Small Egg Tray Machines

- Simple and Stable Structure: The machines use single-sided 3×1 or 4×1 forming systems with fewer moving parts, ensuring reliable and easy maintenance.

- High Efficiency and Low Energy Use: Both models have 38 kW power, producing 1,000–1,500 trays per hour efficiently.

- High Pulp Utilization: Vacuum forming distributes pulp evenly, maximizing material use and reducing waste.

- Durable Materials: Thick Q235 steel frames and corrosion-resistant molds ensure long-lasting stability and quality trays.

- Flexible Drying Options: Air drying, drying box, or drying room can be chosen to match production and climate needs.

- Stable and Reliable Output: Precision forming delivers consistent tray quantity and quality, reducing rework and improving efficiency.

Conclusion

Moving from purchased to in-house trays reflects just one aspect of a poultry farm’s management upgrade.

Essentially, it shows how many farms are moving toward cost control, stable supply, and refined management.

When egg trays become an essential daily consumable, using the right small egg tray machine allows farms to reduce costs and take control of their supply. For poultry farms, the key is no longer whether to produce in-house, but when to start.