Hot Press Forming Machine

| Model | SLZ-150 |

| Overall Size | 1200 × 800 × 1800 mm |

| Working Pressure | 15 tons |

| Working Temperature | 160–200 °C |

| Cycle Time | 6–10 seconds/time |

| Compressed Air Requirement | 0.5–0.6 MPa |

| Certification | TUV、SGS、CE、ISO9001 |

| Warranty | 12 Months |

You can now ask our project managers for technical details

In the pulp molding industry, the hot press forming machine heats the press plates to a set temperature while the hydraulic system applies strong pressure, shaping pulp molded products and giving them a smoother, more attractive appearance.

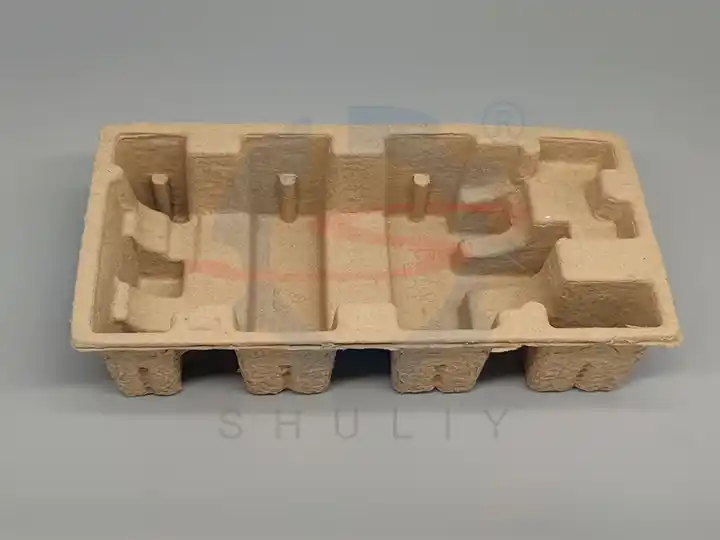

Paper trays shaped by the hot press forming machine have a smooth, dense surface, are less likely to deform, and improve the product’s quality.

This machine uses PLC control, applies 15 tons of pressure with high-temperature forming, and completes each cycle in just 6–10 seconds, quickly shaping various paper trays.

Functions of the Hot Press Forming Machine

The hot press forming machine is the core equipment in high-quality egg tray and paper tray production lines. Its forming effect directly affects the product’s structural stability and surface smoothness.

- High-Temperature Heating: Heats the mold and material so that pulp or fibers soften fully, improving forming quality.

- High-Pressure Forming: Uses hydraulic or mechanical pressure to compress the material, ensuring uniform density, strong structure, and stable dimensions.

- Fast Cycle: Sets forming time to complete pressing, cooling, and demolding in a continuous operation, increasing production efficiency.

- Automatic Control: PLC or touchscreen control allows precise adjustment of temperature, pressure, and time, with built-in safety features.

- Multi-Material Compatibility: Can handle pulp, wood chips, fiberboard, plastic sheets, and other materials, flexibly meeting different product needs.

Applications of the Hot Press Machine

The hot press machine is widely used in producing various pulp molded products. Its high temperature and pressure ensure a strong structure and attractive appearance for paper trays.

Shoe Trays

Shapes pulp into shoe trays with precise form, strong structure, and smooth surface.

Seedling Trays

Forms seedling trays with even holes and good load-bearing, supporting plant growth.

Industrial Packaging Trays

Produces trays for industrial or electronic products, improving strength and protection.

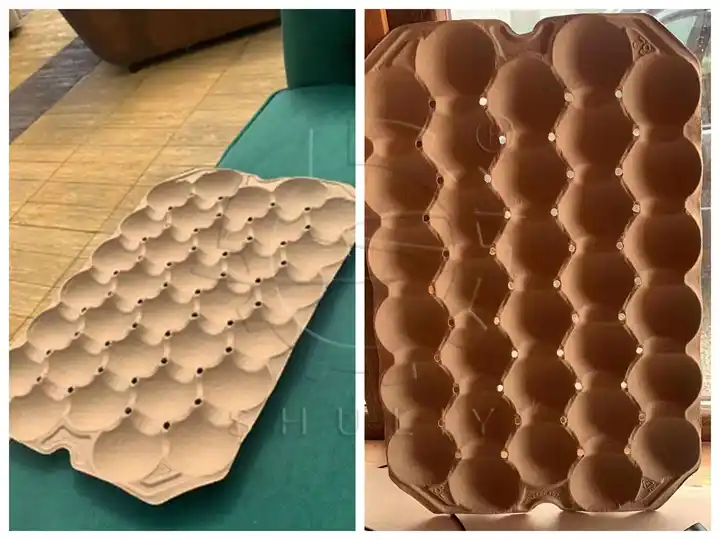

Egg Trays

Shapes egg trays with uniform cells, preventing breakage and ensuring safe transport.

Disposable Food Trays

Produces sturdy disposable trays, easy to carry and use.

Fruit Trays

Form fruit trays with stable support, preventing bruising and squeezing.

Quail Egg Trays

Makes lightweight and sturdy trays for quail eggs, protecting them during transport.

Coffee Cup Trays

Shapes trays with evenly supported cup positions, convenient for carrying.

Working Principle of the Hot Press Forming Machine

The hot press forming machine quickly shapes and dehydrates semi-wet pulp products using high temperature and hydraulic pressure. Heat evaporates moisture in the pulp, while pressure flattens the surface, ensures even thickness, and strengthens the product with stable dimensions. The entire process is managed by a PLC intelligent control system, making operation simple, efficient, and stable. It is a key machine in producing paper trays, egg trays, pulp lunch boxes, and other pulp molded products.

Structure of the Hot Press Machine

The hot press machine consists of cylinders, guide rods, frame, adjustment plate, upper mold, lower mold, pressure regulating valve, and a hydraulic manifold (three-in-one unit).

- Adjustment Plate: Adjusts mold distance or pressure height to fit different pulp thicknesses.

- Upper Mold: Shapes the top surface of the product and applies pressure for hot pressing.

- Lower Mold: Supports the bottom of the product and works with the upper mold to complete forming.

- Hydraulic Manifold (Three-in-One Unit): Controls oil flow, supplying, releasing, and regulating hydraulic pressure.

- Pressure Regulating Valve: Adjusts hydraulic pressure to ensure stable and safe forming.

- Guide Rods: Keep upper and lower molds moving parallel during pressing, improving forming accuracy.

Features of the Hot Press Forming Machine

High Efficiency and Speed

Each cycle takes only 6–10 seconds, enabling mass production.

High Pressure and Temperature

15 tons of pressure combined with 160–200°C heat ensures fast dehydration and forming of paper trays.

Sturdy Structure and Reliable Materials

Frame is made of high-quality welded steel for strong support and durability. Upper and lower molds use high-strength steel plates, and guide rods ensure parallel pressing and product accuracy.

Intelligent Control System

PLC automatically controls temperature, pressure, and time for simple operation and high stability. Pressure is precisely managed via the regulating valve, and the hydraulic system is safe and reliable.

Energy Saving and Environmentally Friendly

Only 6.5 kW power, low energy consumption, high efficiency. Water evaporates evenly during pressing with no pollution, suitable for eco-friendly pulp products.

Precise Adjustment

The adjustment plate allows flexible pressure and mold distance for different product thicknesses. Guide rods and hydraulic manifold ensure even pressure, producing smooth, uniform-thickness products.

Technical Parameters

| Model | SLZ-150 |

|---|---|

| Overall Size | 1200 × 800 × 1800 mm |

| Working Pressure | 15 tons |

| Power | 6.5 kW |

| Working Temperature | 160–200 °C |

| Cycle Time | 6–10 seconds/time |

| Compressed Air Requirement | 0.5–0.6 MPa |

Why Choose Shuliy?

- High Quality and Certification: TUV and SGS supplier evaluation certificates, CE certificate, ISO9001.

- Customized Solutions: Shuliy provides tailored equipment solutions, designing and manufacturing machines to meet different production needs.

- Advanced Production Facilities: A large-scale manufacturing plant with modern equipment and precise production processes ensures high quality and efficiency.

- Professional After-Sales Service: Includes installation, debugging, operation training, and technical support, with a 1-year warranty for worry-free use.

- Rich Experience: Over 20 years of manufacturing and exporting experience, trusted by government and university institutions.

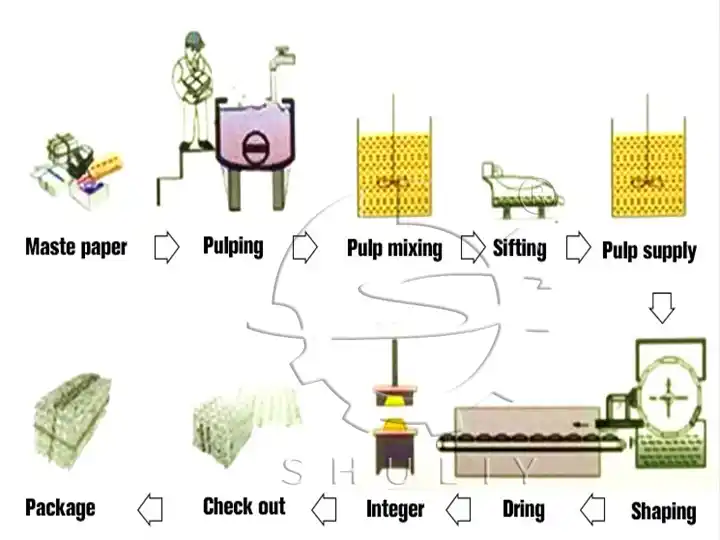

Position in the Workflow

Typical egg tray production line:

Pulping → Forming → Hot Press Forming → Trimming → Drying → Packaging

The hot press molding machine is located after the forming machine and before the trimming machine. It presses the semi-formed egg trays under high temperature and pressure.