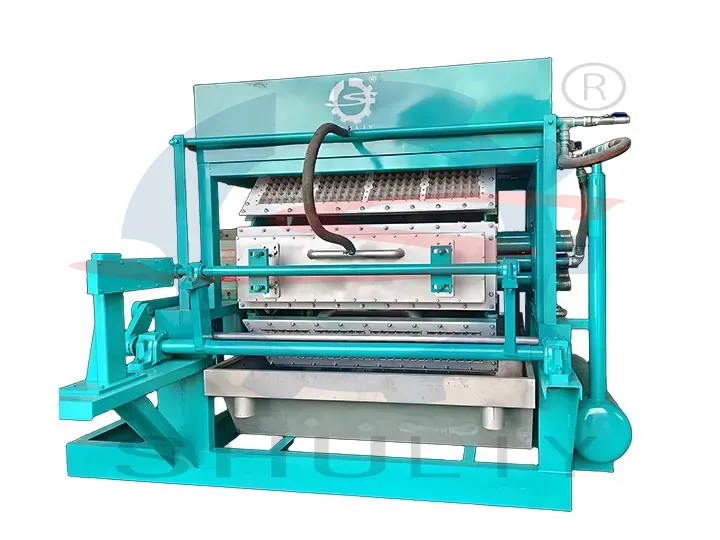

8面蛋托机

| 品牌 | 树立机械 |

| 型号 | SL-4000-4X8;SL-5000-5X8;SL-7000-6X8 |

| 容量 | 4000-7000件/小时 |

| 功率 | 95千瓦;120千瓦 |

| 电压 | 380V, 50HZ |

| 尺寸 | 参考技术参数表 |

| 保修 | 12个月 |

您现在可以向我们的项目经理询问技术细节

8面蛋托机,又称大型蛋托成型机,配备8面转鼓。它能够实现高速、连续生产,特别适合中大型产量需求的工厂。

SL-4000-4*8每小时可生产约4000个蛋托。蛋盘模具可根据买家要求定制。该设备可连续生产,确保产量。此外,由于整个生产过程是回收废纸,没有污染源,因此被称为绿色环保机械。

型号SL-5000-5*8蛋托机每小时可生产约5000个蛋托。它是一款45度角、八盘转盘机。八个盘组成一块板,所有系统都可以连接。该传送臂做90度往复运动。工作效率非常高。

SL-7000-6*8是我们公司产量最高的蛋托成型机,每小时产量高达7,000件。它采用8面转鼓,每面有6个蛋托模具,非常适合大型工厂高效、大规模生产。

8边蛋托机的优势是什么?

- 制作材料 加厚碳钢 耐用且承载能力强

- 铝合金模具(可选不锈钢),轻便,易于干燥和更换

- 可选不粘、高温特氟龙涂层

- 高强度钢传动系统,配有耐磨轴承

- 不锈钢液压管和铜阀,耐腐蚀

- 防水防尘的不锈钢控制柜

- 8边旋转设计使得连续操作,无需频繁停机

- 兼容自动干燥和堆叠系统

- 工业级材料确保超过 10 多年的持续使用

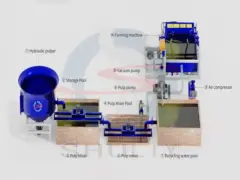

8边旋转鼓蛋托机的结构与生产过程

8面蛋托机主要由制浆系统、成型系统、干燥系统和包装系统组成。

8侧蛋托机的参数

| 型号 | SL-4000-4X8 | SL-5000-5X8 | SL-7000-6X8 |

| 容量 | 4000件/小时 | 5000件/小时 | 7000件/小时 |

| 功率 | 95千瓦 | 95千瓦 | 120千瓦 |

| 电压 | 380V, 50HZ | 380V, 50HZ | 380V, 50HZ |

| 重量 | 7000千克 | 8000千克 | 10000千克 |

| 浆料使用 | 320千克/小时 | 400千克/小时 | 480千克/小时 |

| 水使用 | 640千克/小时 | 800千克/小时 | 960千克/小时 |

| 尺寸(毫米) | 3250*2300*2500 | 3700*2300*2500 | 3200*2300*2500 |

8面 蛋托生产线

作为一家直接制造商,我们可以提供制浆机、空气压缩机、干燥机及其他设备。我们还提供合理的土地布局规划,以帮助降低您的劳动力成本。

太阳干燥

| 项目 | 区域 |

| 机器占地面积 | 30–50 平方米 |

| 干燥场地面积 | 1000 平方米 |

民用建筑干燥机

| 型号 | 长度 (米) | 宽度 (米) | 高度 (米) |

| SL-4×8 | >65 | >15 | >3 |

| SL-5×8 | >65 | >15 | >3 |

| SL-6×8 | = 80 | >15 | >3 |

| SL-8×8 | = 80 | >15 | >3 |

多层干燥机

| 型号 | 长度 (米) | 宽度 (米) | 高度 (米) |

| SL-4×8 | 27.5 | 6 | 3.6 |

| SL-5×8 | 27.5 | 6 | 3.6 |

| SL-6×8 | 33.5 | 6 | 3.6 |

如何制作蛋托?

原材料主要为草浆、纸浆、竹浆、木浆、废纸板、废纸箱纸、废白纸、纸厂尾浆废料等。原材料来源广泛,易于收集。蛋托机是蛋托生产线的主要设备。

将浆料池中的浆料喂入成型机。浆料被真空系统吸收,浆料通过设备上的模具成型。水通过真空泵被吸收并运输回浆料池。水可以被回收利用。

在模具吸附水泥浆后,通过空气压缩机排出转移模具。成品从成型模具吹出到转移模具,然后通过转移模具送出。

蛋托成本分析表

| 成本项目 | 描述 | 每托盘单位成本(人民币) |

| 原材料 | 1吨废纸可以生产 12,000–15,000个托盘 (基于托盘重量)。 基于每个托盘80克:1,000,000克 ÷ 80克 = 12,500个托盘 废纸价格:¥1500/吨 → 1500 ÷ 12,500 = ¥0.12 每个托盘 | ¥0.12 |

| 劳动力 | 阳光干燥:6名工人; 机器干燥:4名工人。 在中国, 劳动通常按件计酬: 每托盘约 ¥0.02。 | ¥0.02 |

| 电力 | 根据容量和功耗而有所不同。 更高的产出意味着每托盘的成本更低。 | ¥0.02 |

| 干燥燃料 | 煤(5000 千卡/千克) 木材(4000 千卡/千克) 天然气 (8900 千卡/立方米) 柴油 (11,900 千卡/升) | ¥0.03/个 ¥0.03/个 ¥0.06/个 ¥0.08/个 |

| 颜料(可选) | ¥12/千克颜料; 1千克可生产 大约3000–4000个托盘 | 大约¥0.003–0.004 |

货币换算:$1(美元)=¥7.2(人民币)

为什么蛋托设备在市场上如此受欢迎?

环保朋友:随着社会的发展,越来越多的人开始关注环境保护问题。环境是人类生存的依赖。因此,我们必须通过各种渠道来保护环境。废纸的回收是保护环境的一种方式。在生产过程中不会产生污染。

功能:蛋托的主要功能是减震。将物品分开,例如易碎物品,以减少在运输或存储过程中物品的破损率。

价格:蛋托机有多种型号可供选择。如果你想从小规模开始创业,这是一个不错的选择。投资不高,机器开始生产后可以收回投资。郑州树立机械提供合理价格的蛋托机出售。

我们合作的客户

运输箱