パルプワイントレイ製造機 | ワイン包装トレイ製造機

| ブランド | シュリ機械 |

| モデル | SLシリーズ |

| 容量 | 1000-7000個/時 |

| パワー | 38-120キロワット |

| 電圧 | 380V、50HZ |

| サイズ | 参考技術パラメータ表 |

| 保証 | 12ヶ月 |

今、私たちのプロジェクトマネージャーに技術的な詳細を尋ねることができます

パルプワイントレイ製造機は、成形されたパルプワイントレイを生産するために設計された産業用機器です。真空成形、プレス、乾燥などのプロセスを使用して、パルプをさまざまなトレイデザインに成形します。

パルプワイントレイは、廃紙、カートン、同様の材料から作られたエコフレンドリーな包装材料で、パルプ成形技術を使用しています。従来のフォーム包装と比較して、パルプワイントレイはより環境に優しく、生分解性があり、優れたクッション性を提供するため、現代のグリーン包装ニーズにより適しています。

This Wine Packaging Tray Making machine plays an important role in modern green packaging production lines, and is especially suitable for making trays for glass bottles such as wine, champagne, and liquor.

Shuliy offers 7 models of pulp molding machines with a capacity of 1,000 to 7,000 pcs/h, exporting over 50 units per year.

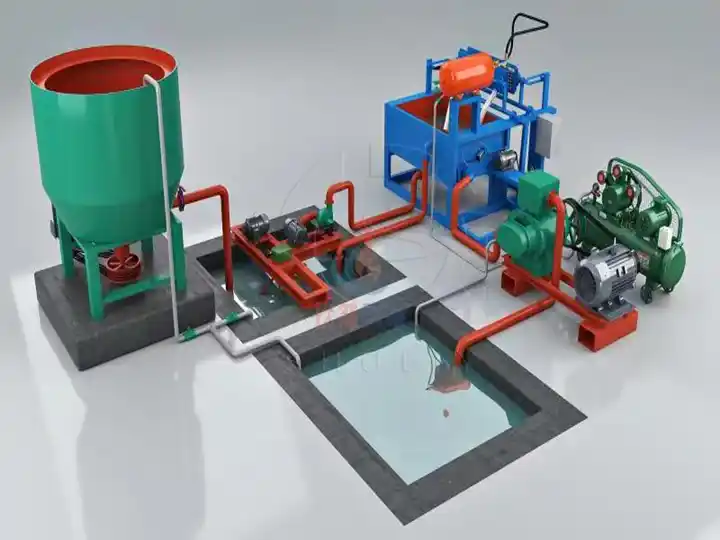

パルプワイントレイ製造機の主構造

The pulp wine tray making machine mainly includes the pulping system, forming system, drying system, and packing system.

- パルピングシステム: これにはパルパー、水タンク、ミキサーが含まれています。廃紙を水と混ぜて滑らかなパルプを作ります。これはパルプ濃度制御装置に接続されています。

- 成形システム: これは、負圧下でパルプを成形するために吸引型の型を使用します。型は上下の部分で構成されており、異なるワインボトルトレイに合わせて迅速に交換できます。成形駆動は油圧式または空気圧式のいずれかです。

- 乾燥システム: 成形後、湿ったトレイは高温で乾燥されます。選択できる乾燥方法は6つあり、自然乾燥、乾燥オーブン、レンガ造りの乾燥室、または多層金属乾燥があります。これにより、トレイのサイズが安定し、表面が滑らかになります。

- 梱包システム: トレイはスタッカーを使用してカウントおよび積み重ねることができ、その後、出荷のために梱包されます。

Shuliyパルプワイントレイ製造機の技術パラメータ

| モデル | 容量 | パワー | 電圧 | 重量 | パルプ使用量 | 水の使用量 | サイズ(mm) |

| SL-1000-3X1 | 1000個/時 | 38kw | 380V、50HZ | 2500kg | 80kg/時 | 160kg/時 | 2600*2200*1900 |

| SL-1500-4X1 | 1500個/時 | 38kw | 380V、50HZ | 3000kg | 120kg/時 | 240kg/時 | 2800*2200*1900 |

| SL-2500-3X4 | 2500個/時 | 55kw | 380V、50HZ | 4000kg | 200kg/h | 400kg/時 | 2900*1800*1800 |

| SL-3000-4X4 | 3000個/時 | 60キロワット | 380V、50HZ | 4800キログラム | 240kg/時 | 480kg/h | 3250*1800*1800 |

| SL-4000-4X8 | 4000個/時 | 95kw | 380V、50HZ | 7000kg | 320kg/時 | 640kg/h | 3250*2300*2500 |

| SL-5000-5X8 | 5000個/時 | 95kw | 380V、50HZ | 8000kg | 400kg/時 | 800kg/h | 3700*2300*2500 |

| SL-7000-6X8 | 7000個/時 | 120kw | 380V、50HZ | 10000kg | 480kg/h | 960kg/h | 3200*2300*2500 |

上記は参考のための標準モデルです。より具体的な要件がある場合は、お客様のニーズに応じて機械をカスタマイズすることもできます。

パルプワイントレイ成形機はどのように機能しますか?

Similar to the egg tray making machine, the pulp wine tray forming machine adopts pulp forming technology. It follows a pulp forming process where the pulp is injected into a mold. Then, the tray is formed by vacuum suction, heat dried, and formed into a tray of special strength and design.

主な作業手順は次のとおりです:パルピング → 成形 → 乾燥 → 梱包。

Shuliyワイン包装トレイ製造機の利点

- 高い自動化パルピングから成形、トリミング、梱包までのプロセスは自動化されており、労働コストを削減します。

- 環境に優しい生産廃水やガスの排出はありません。原材料は再利用可能で、地元の環境政策に適合しています。

- カスタム型: ボルドー、シャンパン、リキュールボトルなど、さまざまなボトルサイズやタイプに適しています。また、送っていただいたボトルに基づいて型をカスタマイズすることも可能です。

- 良好な表面仕上げ: トレイは滑らかで清潔に見え、高級ワインギフトボックスやショールームディスプレイに最適です。色、ロゴのエンボス加工、またはパターンをカスタマイズして、パッケージをアップグレードできます。

- 複数のトレイオプション: 1、2、6、または12本のボトル用のトレイを製造できます。

- 安定した性能: 成形圧力、時間、型のフィットを正確に制御し、一貫した品質を確保します。通常の機械と比較して、2.5倍長く稼働できます。

- 高精度金型システムトレイをより強く、安定させ、良好な重量支持と歪みのないエッジを実現します。トレイには、パフォーマンスを向上させるための対称的な支持点があります。

- カスタムサービスが利用可能です: 私たちは、サンプルベースのデザイン、ボトルサイズのマッチング、ロゴのエンボス加工、色のカスタマイズなどを提供し、あなたのブランドを際立たせるお手伝いをします。トレイ成形機を使用したワンストップのパッケージングソリューションを提供できます。

- フル生産ラインとソリューションが利用可能です: 直接の製造業者として、パルピング機械、エアコンプレッサー、乾燥機、その他の設備を提供できます。また、労働コストを削減するための合理的な土地レイアウト計画も提供しています。

パルプワイントレイの種類は何ですか?

| カテゴリ | タイプ |

| ボトルの容量別 | 187ml、375ml、500ml、700ml、750ml、1L、1.5L、3L / 5L |

| ボトルの数量別 | 1本用、2本用、4本用、6本用、12本用 |

| 構造別 | 一体型、上下分離型、挿入型 |

| 成形プロセス別 | 乾式プレス成形、湿式プレス成形 |

| 使用による | 輸送保護型、ギフトボックスディスプレイ型、輸出型 |

ワイン包装トレイ製造機を選ぶ理由

幅広い用途があります:

- ワイン製造業者: ボトル入りワイン製品の内包装に使用されます。

- Eコマースプラットフォーム: 単一または複数のワインボトルの安全な配送に最適です。

- ギフト包装会社ギフトワインボックスやプレミアムワインセットの内部トレイに使用されます。

- 輸出業者: EU、米国、その他の国のエコ包装規制に準拠しています。

- スーパーマーケットと小売店: コンボパックに使用され、ディスプレイと販売がより便利になります。

他の包装材料に対する利点:

| アイテム | パルプワイントレイ | プラスチックフォームトレイ | 段ボール紙インサート |

| 環境に優しい | 生分解性、エコフレンドリー | 非生分解性 | リサイクル可能 |

| 保護 | 強い | 非常に強い | 中 |

| コスト | 中 | 高い | 低い |

| カスタマイズ | 高い | 中 | 中 |

| 外観 | 良い(湿式圧縮でより良い) | 悪い | 中 |

パルプワイントレイ製造機からの完成品

私たちがよく生産するパルプワイントレイは以下に示されています。しかし、他にも多くの型のオプションがあります。興味があれば、いつでもお気軽にお問い合わせください!

パルプワイントレイ製造機の出荷表示

こちらは私たちの出荷写真のいくつかです。私たちの包装を見てみてください。