コーヒーカップトレイ生産ライン

| 生産能力 | 1000-7000個/時 |

| パルプ材料の負荷 | 1〜1.5 kg/トレイ |

| 真空圧力 | –0.04 〜 –0.06 MPa |

| 熱プレス温度 | 180–250 °C |

| 乾燥方法 | 熱風循環またはレンガ窯乾燥 |

| 電源 | カスタマイズ可能 |

| 型の種類 | 2カップトレイ、4カップトレイ、6カップトレイ、カスタム形状 |

| 保証 | 12ヶ月 |

今、私たちのプロジェクトマネージャーに技術的な詳細を尋ねることができます

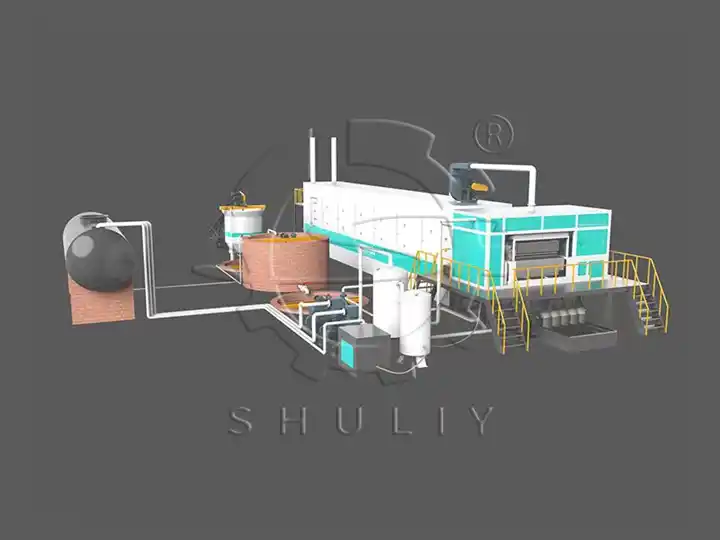

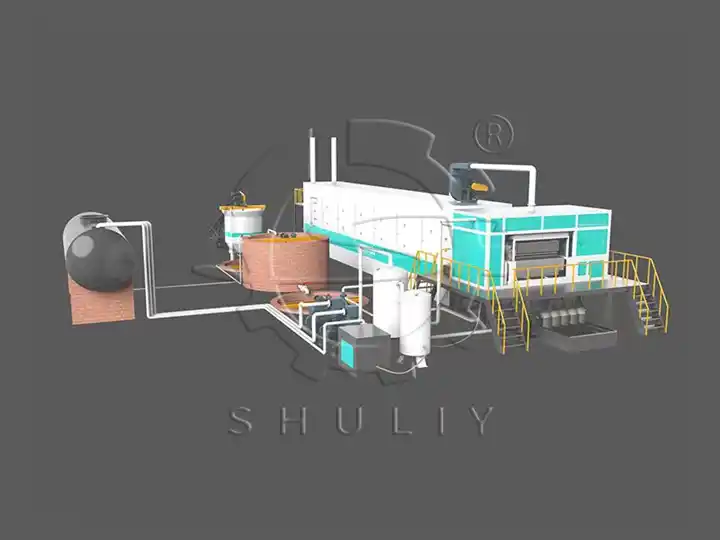

使い捨てコーヒーカップトレイ生産ラインは、完全自動システムです。廃紙、古い段ボール、パルプ板を原料とし、パルプ化、成形、乾燥、熱プレスの4つの主要段階を経て、環境に優しい生分解性のパルプコーヒーカップトレイを製造します。

この生産ラインは、セミオートとフルオートのタイプがあり、 7モデル 利用可能で、容量は 1,000–7,000個/時間です。

Shuliyのコーヒーカップキャリアトレイ生産ラインは、単一、2カップ、または4カップ の生分解性パルプトレイを一つの成形工程で製造でき、テイクアウトサービスに広く利用されています。

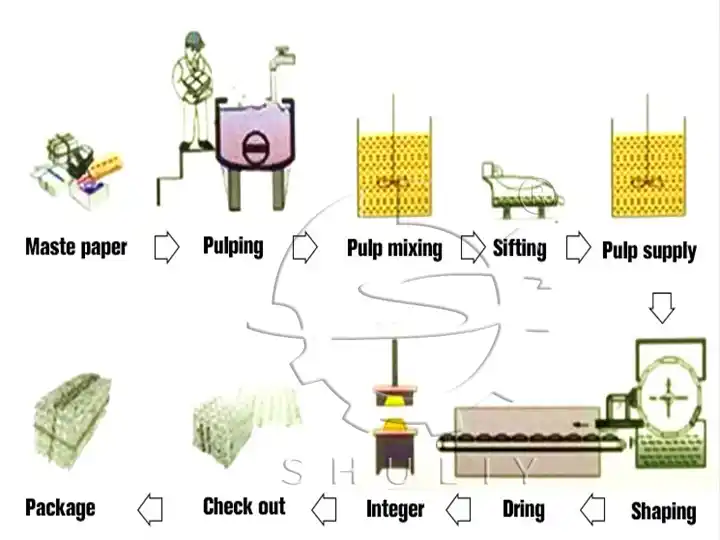

コーヒーカップトレイ生産ラインの動作原理

コーヒーカップトレイは、通常、パルプ成形技術を用いて作られます。基本原理は、廃紙や他の繊維材料をパルプに変え、その後成形、乾燥、熱プレスして、生分解性で環境に優しいコーヒーカップトレイを製造することです。

技術的パラメータ

| アイテム | 仕様 |

|---|---|

| 生産能力 | 1,000–7,000個/時間 |

| パルプ材料の負荷 | 1〜1.5 kg/トレイ |

| 真空圧力 | –0.04 〜 –0.06 MPa |

| 熱プレス温度 | 180–250 °C |

| 乾燥方法 | 熱風循環またはレンガ窯乾燥 |

| 電源 | カスタマイズ可能 |

| 型の種類 | 2カップトレイ、4カップトレイ、6カップトレイ、カスタム形状 |

ベストセラーコーヒーカップトレイ成形機の技術パラメータ

| モデル | 容量 | パワー | 電圧 | 重量 | パルプ使用量 | 水の使用量 | サイズ(mm) |

| SL-1000-3X1 | 1000個/時 | 38kw | 380V、50HZ | 2500kg | 80kg/時 | 160kg/時 | 2600*2200*1900 |

| SL-1500-4X1 | 1500個/時 | 38kw | 380V、50HZ | 3000kg | 120kg/時 | 240kg/時 | 2800*2200*1900 |

| SL-2500-3X4 | 2500個/時 | 55kw | 380V、50HZ | 4000kg | 200kg/h | 400kg/時 | 2900*1800*1800 |

| SL-3000-4X4 | 3000個/時 | 60キロワット | 380V、50HZ | 4800キログラム | 240kg/時 | 480kg/h | 3250*1800*1800 |

| SL-4000-4X8 | 4000個/時 | 95kw | 380V、50HZ | 7000kg | 320kg/時 | 640kg/h | 3250*2300*2500 |

| SL-5000-5X8 | 5000個/時 | 95kw | 380V、50HZ | 8000kg | 400kg/時 | 800kg/h | 3700*2300*2500 |

| SL-7000-6X8 | 7000個/時 | 120kw | 380V、50HZ | 10000kg | 480kg/h | 960kg/h | 3200*2300*2500 |

パルプからコーヒーカップトレイを作る方法は?

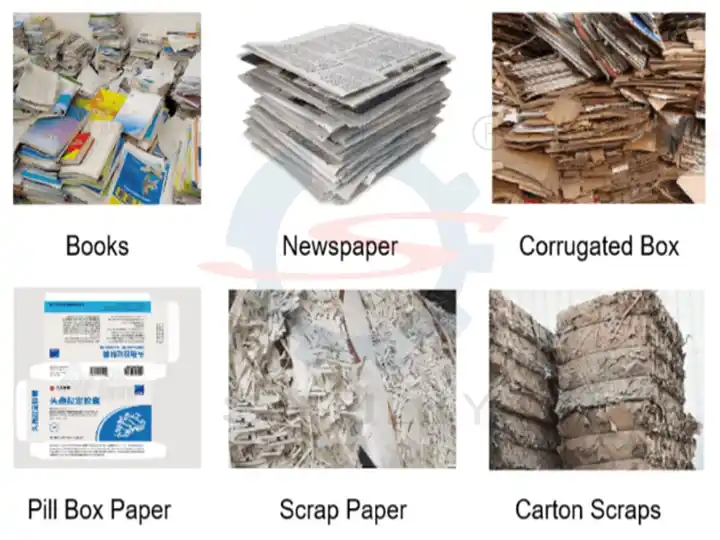

パルプ化

- 廃紙、段ボール、またはリサイクル紙パルプを適量の水とともにパルプ化機に投入します。

- 原材料は細断され、攪拌されて均一で細かいパルプスラリーを形成します。

- オプションの添加剤を加えることで、成形強度や表面の滑らかさを向上させ、次の成形工程に備えます。

成形

パルプコーヒーカップトレイ成形機は、真空吸引を利用して湿ったパルプを金属またはシリコン型に引き寄せます。型は2カップまたは4カップ用に成形されており、真空によりパルプが均一に広がり、初期のトレイ形状を形成します。

脱型と前乾燥

湿ったトレイは型から取り出され、前乾燥エリアに送られ、湿気を除去し、取り扱いを容易にします。

乾燥と熱プレス

乾燥システム(例:ベルト乾燥機)は、残留水分を除去して必要な硬度に達させます。 熱プレスは、トレイの表面とエッジを滑らかにします。

環境に優しい素材

廃紙、パルプ、再生可能素材から作られ、プラスチックは使用していません。トレイは生分解性で、ヨーロッパのEN13432認証などの世界的な環境基準を満たしています。

コーヒーカップキャリアトレイ生産ラインの利点

高い自動化と効率性

- 自動的にパルプ化、成形、乾燥、熱プレス、梱包を完了します。

- 連続生産により安定した出力と高効率を実現し、工業規模の生産に最適です。

- 労働コストを削減し、人為的ミスを最小限に抑えます。

省エネルギーと低消費

- 省エネルギーと高効率のための最適化された乾燥システムと成形プロセス。

- 効率的なエネルギー使用により、生産コストを削減します。

多様なサイズとバリエーション

- 2カップ、4カップ、6カップ、カスタム形状のトレイを製造可能。

- ロゴやブランドを含めるように型をカスタマイズできます。

- さまざまなカップサイズと市場の需要に対応します。

高品質な製品

- 熱プレスと乾燥により、トレイは強く、滑らかで耐久性があります。

- きれいなエッジと変形しにくい安定した製品品質

安定した設備と簡単なメンテナンス

- 設計が良く、耐久性のある設備で、メンテナンスも容易です。

- 低ダウンタイムで安定した運転、長時間の連続生産に適しています。

幅広い用途

- コーヒーショップ、飲料店、テイクアウト包装工場、エコパッケージングメーカーに適しています。

- 異なる生産能力に合わせて、半自動または完全自動ラインが利用可能です。

コーヒーカップトレイ生産ラインの種類

材料取り扱いに応じて、ラインは完全自動または半自動にできます。

セミオートコーヒーカップトレイ生産ライン

ワークフロー:

パルプ化 → 成形 → 湿床皿を手作業で移動 → 乾燥 → ホットプレス → トリミング → 梱包

乾燥方法:

レンガ窯乾燥機または熱風循環乾燥機

完全自動コーヒーカップトレイ生産ライン

ワークフロー:

パルプ化 → 成形 → 自動脱型 → 乾燥 → 熱プレス → トリミング → 自動積み重ね&梱包

全工程は手動作業を要しません。ラインはPLC制御; 操作者はコントロールパネルでパラメータを設定するだけです。

適切な成形コーヒーカップトレイ機械の選び方は?

- 生産規模と予算: 小規模工場は半自動モデルを選択できます。大規模企業には全自動ラインの使用を推奨します。

- 原材料供給: 紙材料の安定した供給源を確保してください。

- 完成品の仕様: トレイの形状や厚さによって異なる金型設計が必要です。

- 工場のスペースとエネルギー設定: これらの要素は乾燥システムの選択に影響します。

カスタマイズ可能なコーヒーカップトレイの種類

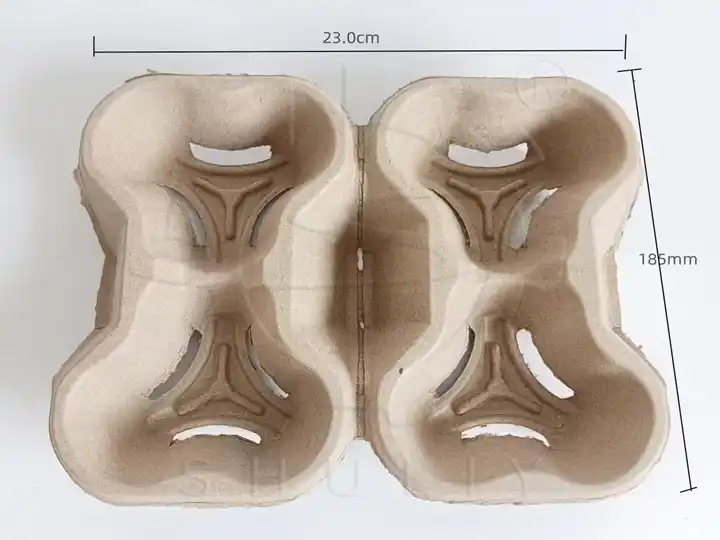

2カップコーヒートレイ

4カップコーヒートレイ

ロゴ入りカスタムトレイ

なぜシュリを選ぶのか?

- 20年以上のパルプ成形機器製造経験

- ワンストップサービス:設計、製造、設置

- 海外サポートも充実:設置、完全ビデオチュートリアル、技術支援

- 専門的な工程ソリューションと技術研修

- 100以上の国に輸出され、顧客満足度は95%以上

- カスタマイズ可能な完全自動および省エネ生産ライン

- 認証済み TUV、SGS、CE、ISO9001

- 1年間の保証

- カスタマイズ可能な電力、電圧、プラグ、型