커피 컵 트레이 생산 라인

| 생산 능력 | 1000-7000개/시간 |

| 펄프 재료 로드 | 트레이당 1–1.5kg |

| 진공 압력 | –0.04 ~ –0.06 MPa |

| 열 프레스 온도 | 180–250 °C |

| 건조 방법 | 열풍 순환 건조 또는 벽돌 가마 건조 |

| 전원 공급 | 맞춤형 |

| 금형 유형 | 2컵 트레이, 4컵 트레이, 6컵 트레이, 맞춤 모양 |

| 보증 | 12개월 |

이제 프로젝트 관리자에게 기술 세부 정보를 문의할 수 있습니다.

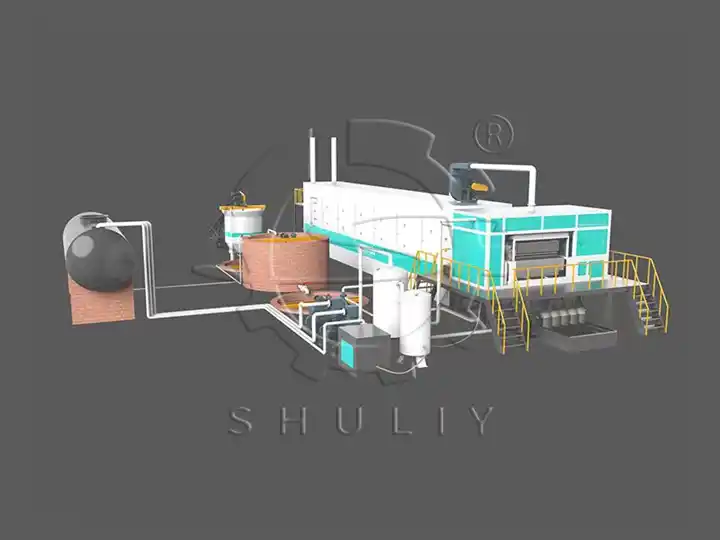

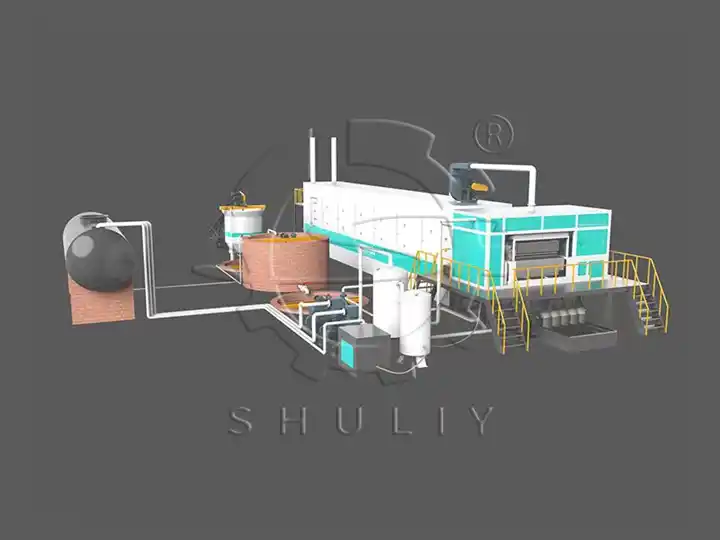

일회용 커피컵 트레이 생산라인은 완전 자동 시스템입니다. 폐지, 낡은 상자, 펄프 보드 등을 원료로 사용하고, 펄핑, 성형, 건조, 열프레스의 네 가지 주요 공정을 거쳐 친환경적이고 생분해성인 펄프 커피컵 트레이를 생산합니다.

생산 라인은 반자동 및 전자동 유형으로 제공되며 7가지 모델 이 있으며, 시간당 생산량은 1,000–7,000개입니다.

Shuliy의 커피컵 캐리어 트레이 생산 라인은 단일, 2컵 또는 4컵 생분해성 펄프 트레이를 한 번의 성형 공정으로 제조할 수 있으며, 테이크아웃 서비스에 널리 사용됩니다.

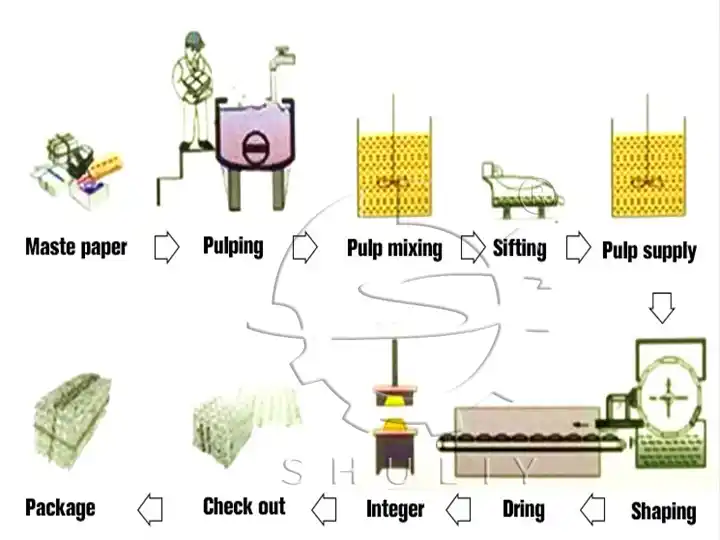

커피컵 트레이 생산 라인의 작동 원리

커피컵 트레이는 일반적으로 펄프 주조 기술로 제작됩니다. 핵심 원리는 폐지나 다른 섬유 재료를 펄프로 만들고, 성형, 건조, 그리고 열프레스로 가공하여 생분해성의 친환경 커피컵 트레이를 생산하는 것입니다.

기술 사양

| 항목 | 사양 |

|---|---|

| 생산 능력 | 1,000–7,000개/시간 |

| 펄프 재료 로드 | 트레이당 1–1.5kg |

| 진공 압력 | –0.04 ~ –0.06 MPa |

| 열 프레스 온도 | 180–250 °C |

| 건조 방법 | 열풍 순환 건조 또는 벽돌 가마 건조 |

| 전원 공급 | 맞춤형 |

| 금형 유형 | 2컵 트레이, 4컵 트레이, 6컵 트레이, 맞춤 모양 |

베스트셀러 커피 컵 트레이 성형기의 기술 파라미터

| 모델 | 용량 | 전력 | 전압 | 무게 | 펄프 사용량 | 물 사용량 | 크기(mm) |

| SL-1000-3X1 | 1000개/시간 | 38kw | 380V, 50HZ | 2500kg | 80kg/시간 | 160kg/h | 2600*2200*1900 |

| SL-1500-4X1 | 1500개/시간 | 38kw | 380V, 50HZ | 3000kg | 120kg/시간 | 240kg/h | 2800*2200*1900 |

| SL-2500-3X4 | 2500개/시간 | 55kw | 380V, 50HZ | 4000kg | 200kg/h | 400kg/h | 2900*1800*1800 |

| SL-3000-4X4 | 3000개/시간 | 60kw | 380V, 50HZ | 4800kg | 240kg/h | 480kg/h | 3250*1800*1800 |

| SL-4000-4X8 | 4000개/시간 | 95kw | 380V, 50HZ | 7000kg | 320kg/시간 | 640kg/시간 | 3250*2300*2500 |

| SL-5000-5X8 | 5000개/h | 95kw | 380V, 50HZ | 8000kg | 400kg/h | 800kg/h | 3700*2300*2500 |

| SL-7000-6X8 | 7000개/h | 120kw | 380V, 50HZ | 10000kg | 480kg/h | 960kg/h | 3200*2300*2500 |

펄프에서 커피컵 트레이를 만드는 방법?

펄핑

- 폐지, 골판지 또는 재생지 펄프를 적당한 양의 물과 함께 펄핑 기계에 공급합니다.

- 원료를 잘게 파쇄하고 저어 균일하고 미세한 펄프 슬러리를 형성합니다.

- 선택적 첨가제를 추가하여 성형 강도나 표면 매끄러움을 개선하고 후속 성형 공정을 위한 펄프를 준비합니다.

주조 성형

펄프 커피컵 트레이 성형기는 진공 흡입으로 젖은 펄프를 금속 또는 실리콘 금형으로 끌어당깁니다. 금형은 2컵 또는 4컵에 맞춰 형성됩니다. 진공으로 펄프가 고르게 퍼져 초기 트레이 모양을 형성합니다.

탈형 및 예건조

젖은 트레이를 금형에서 제거하고 예건조 구역으로 보내 일부 수분을 제거하여 취급을 용이하게 합니다.

건조 및 열프레스

건조 시스템(예: 벨트 건조)가 남아 있는 수분을 제거하여 필요한 경도를 달성합니다. 열프레스 트레이의 표면과 가장자리를 매끈하게 다듬습니다.

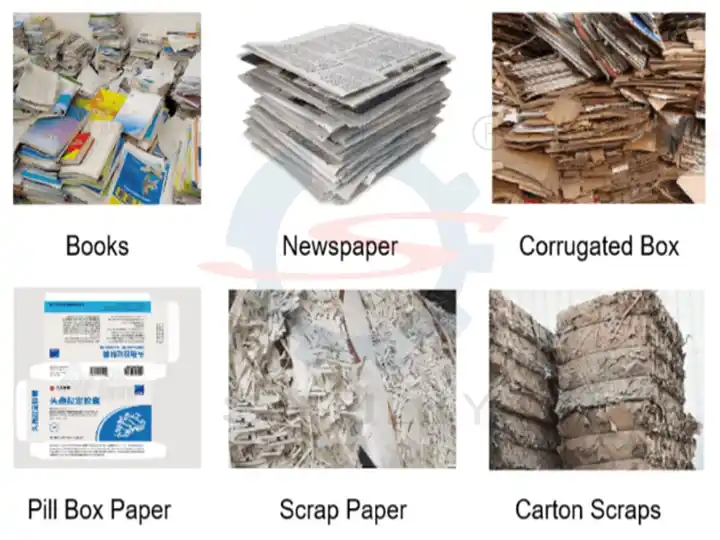

친환경 소재

폐지, 펄프 또는 재생 가능한 재료로 만들어지며 플라스틱이 전혀 포함되지 않습니다. 트레이는 생분해 가능하고 유럽의 EN13432 인증과 같은 글로벌 환경 표준을 충족합니다.

커피 운반용 트레이 생산 라인의 장점

높은 자동화 및 효율성

- 펄핑, 성형, 건조, 열프레스, 포장을 자동으로 완료합니다.

- 연속 생산으로 안정적 출력과 높은 효율을 보장하며 산업용 대규모 생산에 이상적입니다.

- 노동 비용 절감과 사람의 실수 최소화.

에너지 절약 및 저소비

- 낮은 에너지 사용과 높은 효율을 위한 최적화된 건조 시스템 및 성형 공정.

- 에너지 효율적인 사용으로 생산 비용 절감.

다양한 사이즈와 다양성

- 2컵, 4컵, 6컵 및 맞춤형 형태 트레이 생산 가능.

- 로고나 브랜드를 포함하도록 금형을 맞춤화할 수 있습니다.

- 다양한 컵 크기와 시장 수요에 맞춘 설계.

고품질 제품

- 열프레스와 건조로 트레이를 강하고 매끄럽고 내구성 있게 만듭니다.

- 모서리가 깔끔하고 변형 저항이 높은 안정적인 제품 품질.

안정적인 설비 및 쉬운 유지보수

- 디자인이 잘 되어 있고 내구성이 뛰어난 설비로 유지보수가 쉽습니다.

- 가동 안정성 높고 가동 중단이 적어 장기 연속 생산에 적합합니다.

넓은 적용성

- 커피숍, 음료 매장, 포장 배달 공장, 친환경 포장 제조사에 적합합니다.

- 다양한 생산 능력에 맞춰 반자동 또는 전자동 라인을 선택 가능.

커피컵 트레이 생산 라인의 유형들

재료 취급에 따라 전자동 또는 반자동으로 구성 가능.

반자동 커피컵 트레이 생산 라인

작업 흐름:

펄핑 → 성형 → 습식 변 수작업 이송 → 건조 → 열 압착 → 트리밍 → 포장

건조 방식:

벽돌 가마 건조기 또는 열풍 순환 건조기

전자동 커피컵 트레이 생산 라인

작업 흐름:

펄핑 → 성형 → 자동 탈형 → 건조 → 열프레스 → 트리밍 → 자동 적재 및 포장

전체 공정은 수작업이 필요 없음. 라인은 PLC 시스템으로 제어; 작업자는 제어판에서 매개변수만 설정하면 됨

적합한 금형 기계 선택 방법?

- 생산 규모 및 예산: 소규모 공장은 반자동 모델을 선택할 수 있으며; 대기업은 전자동 라인 사용을 권장합니다.

- 원자재 공급: 종이 재료의 안정적인 공급원을 확보하세요.

- 완제품 사양: 다른 트레이 모양과 두께는 다양한 금형 설계를 필요로 합니다.

- 공장 공간 및 에너지 설비: 이러한 요소들은 건조 시스템 선택에 영향을 미칩니다.

맞춤 가능한 커피컵 트레이 타입

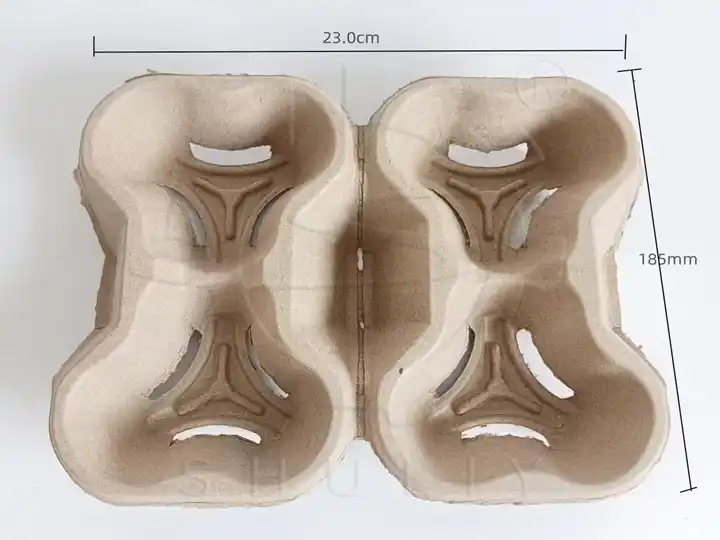

2컵 커피 트레이

4컵 커피 트레이

로고가 있는 맞춤 트레이

왜 슐리야를 선택해야 할까요?

- 펄프 성형 설비 제조 경력 20년 이상

- 원스톱 서비스: 디자인, 생산, 설치

- 해외 종합 지원: 설치, 전체 영상 튜토리얼, 기술 지원

- 전문적 공정 솔루션 및 기술 교육

- 100개국 이상으로 수출, 고객 만족도 95% 이상

- 맞춤형 전자동 및 에너지 절약 생산 라인

- 인증받은 TUV, SGS, CE, 및 ISO9001

- 1년 보증

- 맞춤 가능한 전력, 전압, 플러그 및 금형