ギニアのお客様が注文したSL-4*1小さな卵トレイ機械は出荷されました

2025年10月、シュリはギニアの顧客にSL-4*1小卵トレイ機を成功裏に納品しました。注文前に顧客は工場を訪れ、卵トレイの生産工程を検査しました。現場でのテスト、騒音比較、金型の品質検査の後、顧客はその場で注文を確定しました。現在、機械は生産され、梱包され、ギニアへ出荷されています。

顧客背景

ギニアの顧客は、小卵トレイ機のために地元の卵包装工場を建設しています。近隣に住民がいるため、特に4つの重要な問題に関心を持っています:

- エアコンプレッサーの騒音が周囲環境に影響を与えるかどうか。

- 全成形機がスムーズかつ静かに動作するかどうか。

- 型のカスタマイズはサポートされていますか。

- 実際の生産における卵トレイのサイズの正確さ。

したがって、顧客は現地検査のために中国の工場を訪問することを決定しました。シュリは顧客を温かく迎え、全生産ラインの見学と機械のテストを手配しました。

シャリーソリューション

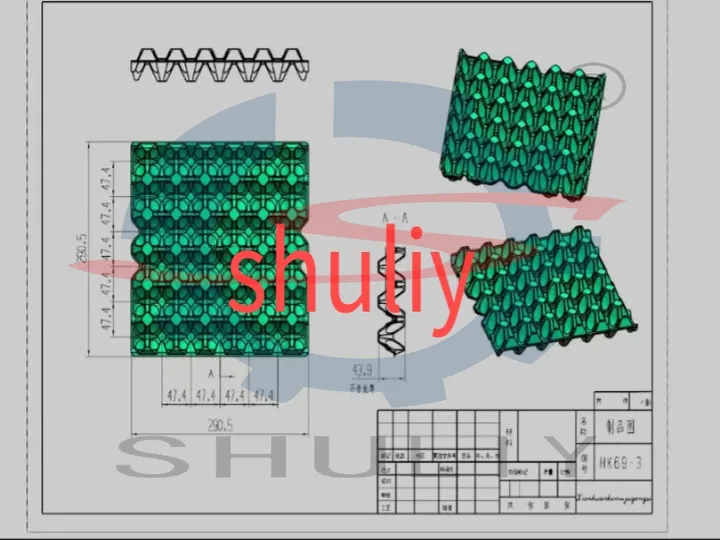

- 顧客のために3D図面を使用したカスタマイズされた成形金型。

- 顧客検査のために同様のサイズのサンプル卵トレイを現場で製造しました。

- 卵トレイ全体とエアコンプレッサーの騒音テストを実施しました。

工場現地検査

全機騒音テスト

SL-4*1小卵トレイ成形機のライブデモンストレーションが工場内で行われました。

- 金型の吸引、材料の落下、転送動作はスムーズでした。

- 空気排出は均一で、異常な振動はありませんでした。

- 顧客は低騒音レベルに非常に満足し、室内生産工場に完全に適していると考えました。

エアコンプレッサー騒音デモンストレーション

顧客はエアコンプレッサーの動作に注目しました:

- 安定した音、普通の工場設備より騒音が低い。

- 目立った振動はありません。

- 空気圧出力が滑らかで、成形システムと完全に一致しています。

顧客のコメント:「この騒音レベルは私たちの工場では完全に許容範囲です。」

プラスチック金型の品質検査

顧客は金型を一つずつ取り外して検査しました:

- 軽量で取り付けやメンテナンスが容易。

- 表面が滑らかで、成形穴が均一です。

- 錆びにくく、ギニアの湿気の多い環境に理想的です。

顧客は特にプラスチック金型を評価しました。地元の金属金型は腐食しやすいためです。プラスチック金型は将来のメンテナンスコストを大幅に削減します。

制御キャビネットと電気システムのデモンストレーション

エンジニアがSL-4*1小卵トレイ機の電気構造を説明しました:

- タイムリレー

- 中間リレー

- 交流接触器

- エアスイッチ

- ノブスイッチ、非常停止、安全表示灯

顧客は配線が整然としており、構造が明確で、将来のメンテナンスが容易であると指摘しました。

SL-4*1小卵トレイ製造機の技術パラメータ

- モデル:SL-4*1

- 電力:3 kW

- 寸法:3.1 × 1.7 × 1.8 m

- 作業速度:6–14サイクル/分

- テンプレート:2個

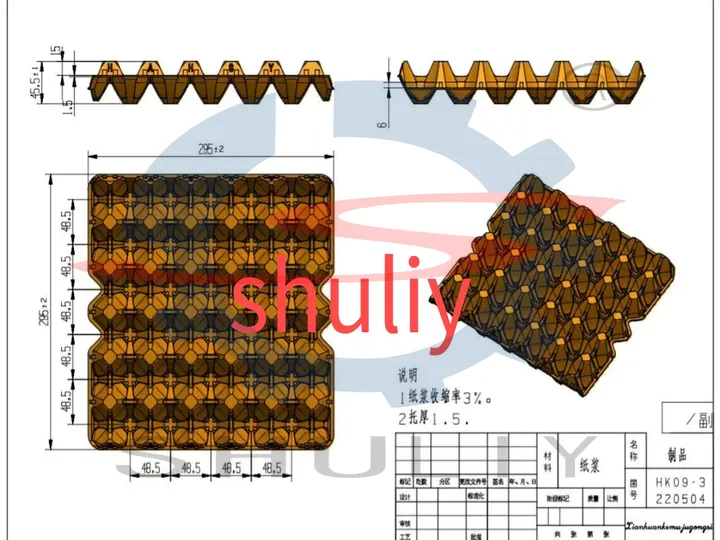

金型構成(プラスチック金型)

- 成形金型:4個(295 × 295 mm)

- 転送金型:4個(295 × 295 mm)

アクセサリーと空気圧システムの構成

| アイテム | 仕様 | 数量 |

|---|---|---|

| 近接スイッチ | 金属誘導タイプ | 4個 |

| 電磁弁 | 電気制御タイプ | 2個 |

| 空気蝶番弁 | DN100 | 1個 |

| 2位置5通弁 | 220V、50Hz、10 mm口径 | 1個 |

| 手動弁 | 10 mm口径 | 1個 |

| エアシリンダー | SC100 × 250(2つの調整弁付き) | 1個 |

| ステンレス鋼ボールバルブ | DN16、ステンレス鋼素材 | 3個 |

| 高圧ホース | 1.5 m(1台)、1 m(1台) | 2個 |

すべての空気圧コンポーネントはエアコンプレッサーと一致してテストされており、納品時にすぐ使用できる状態です。

設備の梱包と出荷

小卵トレイ機、金型、制御キャビネット、すべての空気圧アクセサリーは、輸出基準に従って木箱に強化梱包されています。商品はすでに積み込み、港に送られ、間もなくギニアの顧客の工場に到着します。

結論

この工場見学を通じて、顧客はシュリの生産能力、設備の品質、騒音制御性能を高く評価しました。

SL-4*1 小卵トレイ機 はギニアの顧客が地元の卵トレイ生産を成功させるのに役立ち、生産能力と製品品質の両方を向上させます。

パルプ卵トレイ、フルーツトレイ、またはパッケージトレイの生産ラインを構築する予定があれば、右側のいずれかの窓からお気軽にお問い合わせください。無料の設計ソリューションと技術サポートを提供します。