Mesin Pembuat Baki Cangkir Kopi

| Merek | Mesin Shuliy |

| Model | Seri SL |

| Kapasitas | 1000-7000pcs/jam |

| Daya | 38-120kw |

| Tegangan | 380V,50HZ |

| Ukuran | Tabel Parameter Teknis Referensi |

| Garansi | 12 bulan |

Anda sekarang dapat meminta detail teknis kepada manajer proyek kami

Mesin pembuat nampan cangkir kopi, juga dikenal sebagai mesin pembentuk nampan cangkir cetakan pulp, dirancang untuk menghasilkan nampan ramah lingkungan yang menampung 2 atau 4 cangkir kopi. Nampan ini dibentuk dalam satu siklus dan banyak digunakan dalam layanan pesan antar.

Mesin ini menawarkan kinerja yang stabil dengan 7 model yang tersedia, menghasilkan hingga 1.000–7.000 pcs/jam. Mesin ini juga dapat dipasangkan dengan sistem pengeringan logam otomatis penuh untuk jalur produksi yang lengkap dan efisiensi yang lebih tinggi.

Mesin pembentuk nampan cangkir cetakan pulp banyak digunakan di kedai kopi, layanan bawa pulang, dan rantai minuman, memastikan transportasi minuman yang aman dan nyaman.

Sejak 2011, kami telah menyediakan mesin pembentuk nampan cangkir ke lebih dari 30 negara, dengan 50+ unit terjual setiap tahunnya.

Apa Itu Piring Kopi Terbuat Dari?

Nampan cangkir kopi adalah produk cetakan pulp yang khas, dibuat terutama dari bahan kertas daur ulang. Bahan baku ini memiliki biaya rendah, ramah lingkungan, dan mendukung pembangunan berkelanjutan.

Bahan utama termasuk:

- Koran lama

- Kardus bergelombang

- Kertas buku dan majalah

- Sampah kertas kantor

- Papan pulp

- Sisa pabrik kertas, dll.

Mesin Pembuat Piring Kopi Bernilai Tinggi

Mesin pembentuk nampan cangkir kopi kami menggabungkan material berkekuatan tinggi, teknologi canggih, dan sistem kontrol cerdas untuk memberikan solusi yang efisien, stabil, dan tahan lama untuk memproduksi kemasan pulp cetakan ramah lingkungan dalam jumlah besar.

Bahan Premium untuk Daya Tahan Jangka Panjang

Komponen utama terbuat dari baja 40Cr dan baja tahan karat 304:

- 40Cr menawarkan kekuatan dan ketahanan yang sangat baik, ideal untuk bagian bergerak yang mengalami stres tinggi.

- 304 stainless steel memberikan ketahanan korosi yang superior, menjadikannya sempurna untuk lingkungan pulp yang lembab dan sangat memperpanjang umur mesin.

Kontrol Kualitas yang Ketat

Setiap mesin melalui proses inspeksi penuh sebelum pengiriman, termasuk:

- Pengujian kontrol listrik

- Pemeriksaan presisi cetakan

- Uji coba dan pengujian operasional

Setelah pemasangan, insinyur kami mengumpulkan data langsung untuk memastikan kinerja yang stabil dan efisien di lokasi.

Lini Produksi yang Sepenuhnya Otomatis

Seluruh proses — pulping, pembentukan, pelepasan cetakan, pengangkutan, pengeringan, dan penumpukan — dapat sepenuhnya otomatis.

Ini secara signifikan mengurangi biaya tenaga kerja dan sangat cocok untuk produksi bervolume tinggi, terutama pesanan ekspor dan proyek OEM/ODM kustom.

Struktur Diperkuat untuk Penggunaan Jangka Panjang

Semua komponen yang mengalami stres tinggi dioptimalkan dalam desain dan dibuat dengan bahan berkualitas tinggi untuk menahan kelelahan dan deformasi — ideal untuk operasi berkelanjutan dengan frekuensi tinggi.

Kompatibel dengan Jalur Pengeringan

Mesin kami terintegrasi dengan pengering kontinu 6-lapis kami, memungkinkan pengeringan cetakan tray yang cepat dan merata. Ini mengurangi waktu pengeringan dan meningkatkan output harian — sempurna untuk produksi skala besar.

Teknologi Pencetakan Rotary

Dilengkapi dengan sistem pencetakan pulp putar terbaru kami, mesin ini memastikan pemberian pulp yang terus menerus, pembentukan, dan pelepasan, memberikan kecepatan yang lebih tinggi dan konsistensi dalam kualitas baki.

Kustomisasi Tersedia

Kami mendukung ukiran logo, bentuk kustom, kustomisasi cetakan, dan peningkatan atau modifikasi mesin untuk memenuhi kebutuhan merek dan produksi Anda.

Keahlian Pengelasan yang Unggul

Kami menggunakan teknik pengelasan standar tinggi untuk memastikan kekuatan struktural dan penyegelan yang kedap udara, mengurangi risiko deformasi atau pelonggaran selama operasi jangka panjang.

Spesifikasi Teknis

| Model | Kapasitas | Daya | Tegangan | Berat | Penggunaan Pulp | Penggunaan Air | Ukuran(mm) |

| SL-1000-3X1 | 1000pcs/jam | 38kw | 380V,50HZ | 2500kg | 80kg/jam | 160kg/jam | 2600*2200*1900 |

| SL-1500-4X1 | 1500pcs/jam | 38kw | 380V,50HZ | 3000kg | 120kg/jam | 240kg/jam | 2800*2200*1900 |

| SL-2500-3X4 | 2500pcs/jam | 55kw | 380V,50HZ | 4000kg | 200kg/jam | 400kg/jam | 2900*1800*1800 |

| SL-3000-4X4 | 3000pcs/jam | 60kw | 380V,50HZ | 4800kg | 240kg/jam | 480kg/jam | 3250*1800*1800 |

| SL-4000-4X8 | 4000pcs/jam | 95kw | 380V,50HZ | 7000kg | 320kg/jam | 640kg/jam | 3250*2300*2500 |

| SL-5000-5X8 | 5000pcs/jam | 95kw | 380V,50HZ | 8000kg | 400kg/jam | 800kg/jam | 3700*2300*2500 |

| SL-7000-6X8 | 7000pcs/jam | 120kw | 380V,50HZ | 10000kg | 480kg/jam | 960kg/jam | 3200*2300*2500 |

Catatan: Spesifikasi dapat bervariasi tergantung pada ukuran nampan dan metode pengeringan.

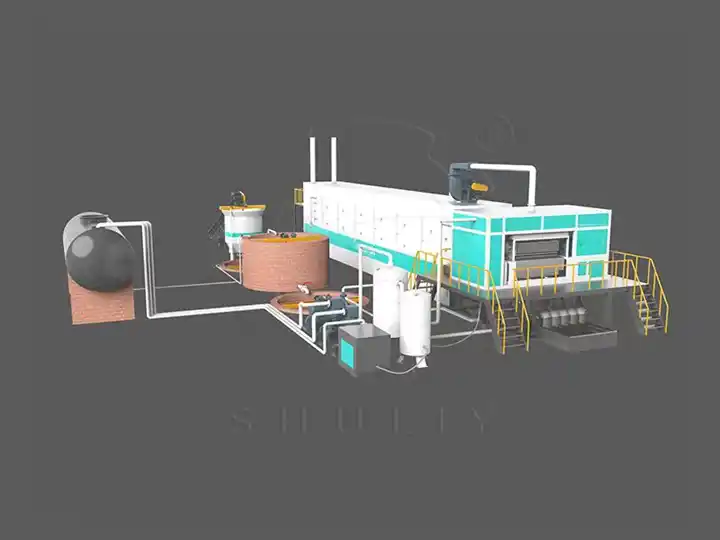

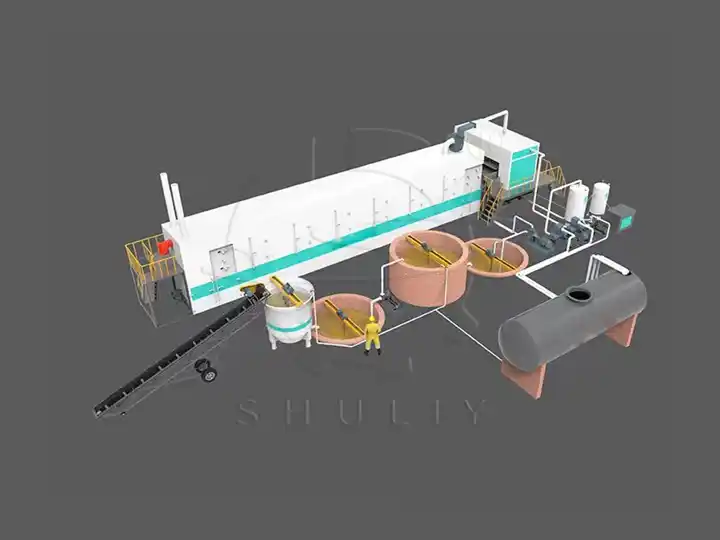

Lini Produksi Tray Cangkir Kopi

Kami juga menawarkan jalur produksi nampan kopi otomatis penuh, biasanya terdiri dari sistem berikut:

Sistem pulping, sistem pembentukan, sistem pengeringan, sistem pengepresan panas, dan sistem penumpukan & pengemasan.

Perusahaan penyedia kopi, pabrik kemasan cetakan pulp, dan perusahaan kemasan ramah lingkungan secara luas menggunakan jenis jalur produksi ini. Piring yang dihasilkan dapat terurai secara hayati dan ramah lingkungan, menjadikannya pengganti yang ideal untuk pemegang cangkir plastik tradisional.

Proses Produksi Mesin Tray Cangkir Kopi

Proses produksi umumnya mencakup lima langkah utama:

Pengolahan

Kertas bekas dicampur dengan air dan dihancurkan menjadi pulp. Setelah kotoran disaring, pulp disimpan dalam kolam pulp untuk digunakan.

Pembentukan

Pulp dibentuk dengan vakum ke dalam cetakan untuk membentuk nampan kopi (seperti tempat untuk 2 cangkir atau 4 cangkir), kemudian secara otomatis dicabut dari cetakan.

Pengeringan

Nampan basah diangkut ke dalam pengering multi-lapis untuk dikeringkan dan dibentuk dengan cepat.

Tekan Panas (Opsional)

Mesin pemanasan panas meningkatkan kekuatan dan kehalusan nampan, memperbaiki penampilan dan integritas strukturnya.

Penumpukan & Pengemasan

Nampan yang sudah jadi secara otomatis atau manual ditumpuk, dihitung, dan dikemas untuk pengiriman.

Diagram Alir

Kertas bekas → Pulping → Pembentukan → Pengeringan → Pengepresan Panas → Pengemasan

Mesin pemanas panas bersifat opsional dan dapat ditambahkan tergantung pada kebutuhan kualitas produk Anda.

Setiap mesin dalam jalur produksi juga dapat dijual secara terpisah.

Kami menawarkan konsultasi gratis dan solusi yang disesuaikan berdasarkan anggaran dan kebutuhan produksi Anda yang sebenarnya.

Layanan Kustomisasi Cetakan

Untuk memenuhi berbagai kebutuhan pelanggan terkait ukuran produk, desain, dan personalisasi merek, kami menawarkan layanan cetakan khusus untuk nampan cangkir kopi. Berikut adalah proses dan poin-poin penting yang perlu diperhatikan:

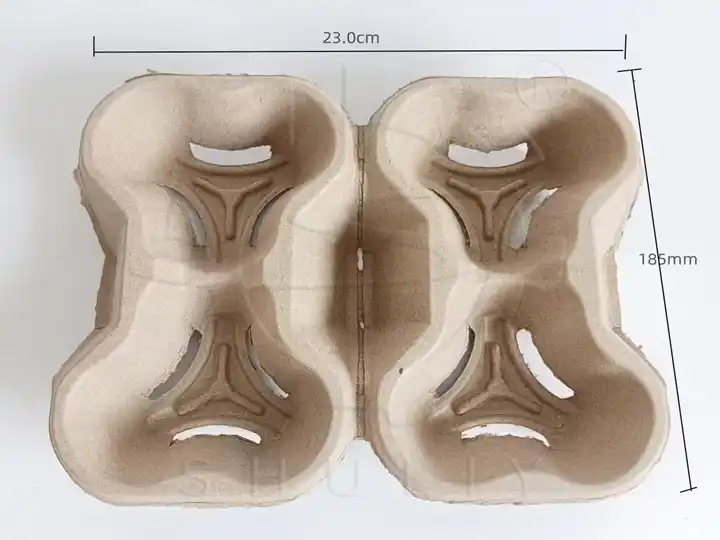

Tampilan Cetakan

Langkah 1: Berikan Persyaratan Desain atau Sampel

Anda dapat mengajukan salah satu dari berikut ini sebagai referensi untuk kustomisasi cetakan:

Sampel fisik (misalnya, nampan 2-cup atau 4-cup yang umum terlihat di pasar)

- 3D gambar \/ CAD file (format seperti .STEP, .DWG, dll.)

- sketsa tangan dengan dimensi (panjang, lebar, tinggi, diameter cangkir, dll.)

- Karya seni logo merek (jika embossing logo diperlukan)

Langkah 2: Pembuatan Cetakan

Setelah desain dikonfirmasi, kami melanjutkan ke produksi cetakan:

- Bahan: Cetakan dari paduan aluminium berkualitas tinggi atau stainless steel

- Waktu tunggu: 10–15 hari kerja (tergantung pada kompleksitas)

- Opsi: Cetakan tunggal, ganda, atau multi-cavity untuk meningkatkan output

Langkah 3: Pengujian Cetakan

Setelah produksi, kami melakukan uji coba pada mesin pembentuk untuk memastikan:

- Pembentukan yang akurat dan pas slot cangkir

- Embossing logo yang jelas dan tepat

- Proses pengeluaran yang halus

Produksi batch hanya dimulai setelah konfirmasi penuh.

Langkah 4: Pengiriman & Integrasi Mesin

Kami menawarkan opsi pengiriman yang fleksibel:

- Mold dikirim terpisah

- Mold dikirim dengan set mesin lengkap

- Dikemas dan dikirim setelah instalasi dan pengujian di lokasi

Kami Menawarkan

- Konsultasi desain gratis

- Kustomisasi cetakan batch kecil

- Layanan satu atap: cetakan + mesin

- Dukungan multibahasa (Cina / Inggris / Spanyol)

Dimensi Nampan Cangkir Kopi

Bagaimana Memilih Mesin Pembuat Tray Cangkir Kopi yang Tepat?

Memilih model yang tepat tergantung pada skala produksi, anggaran, dan kebutuhan output Anda. Berikut adalah panduan dasar untuk membantu Anda memutuskan:

Produksi Skala Kecil

Kapasitas yang Direkomendasikan: 1000-1500pcs/jam

Model yang Direkomendasikan: SL-1000-3X1, SL-1500-4X1

Cocok Untuk: Startup, kemasan makanan lokal, dan bisnis kemasan ramah lingkungan kecil

Produksi Skala Menengah

Kapasitas yang Direkomendasikan: 2000-3000pcs/jam

Model yang Direkomendasikan: SL-2500-3X4, SL-3000-4X4, SL-4000-4X8

Cocok Untuk: Pabrik kemasan yang sedang berkembang, pemasok regional, pesanan OEM

Produksi Skala Besar

Kapasitas yang Direkomendasikan: 4000-5000pcs/jam

Model yang Direkomendasikan: SL-4000-4X8, SL-5000-5X8, SL-7000-6X8

Cocok Untuk: Produsen besar, eksportir, merek nasional, proyek OEM/ODM bervolume tinggi

Sertifikasi Kami

Kami berkomitmen pada kualitas dan kepatuhan. Mesin kami bersertifikat untuk memenuhi standar internasional.

Dipercaya oleh Klien Global

Sejak 2011, mesin nampan kopi kami telah diekspor ke lebih dari 30 negara, termasuk:

AS, Kanada, Inggris, Australia, Vietnam, India, Nigeria, Ghana, Afrika Selatan, Kolombia, dan lainnya.

Rekomendasi Mesin Terkait

FAQ: Pertanyaan Umum Tentang Mesin Tray Cangkir Kopi

Jenis tray apa yang dapat diproduksi oleh mesin pembentuk tray cangkir kopi?

Terutama tray kopi pulp 2-cangkir dan 4-cangkir. Cetakan kustom dapat dibuat berdasarkan kebutuhan pelanggan, seperti embossing logo atau ukuran yang berbeda.

Apakah peralatan ini sepenuhnya otomatis?

Ya, kami menawarkan lini produksi otomatis sepenuhnya yang mencakup pengolahan, pembentukan, pengeringan, pemanasan (opsional), penumpukan, dan pengemasan. Opsi semi-otomatis juga tersedia, tergantung pada anggaran.

Apa kapasitas produksi mesin pembuat tray kopi?

Kapasitas bervariasi berdasarkan model, biasanya antara 1.000 hingga 7.000 nampan per jam. Kami dapat merekomendasikan model yang sesuai berdasarkan kebutuhan produksi Anda.

Metode pengeringan apa saja yang tersedia?

Berbagai opsi pengeringan, termasuk:

* Pengering logam multi-lapis (listrik, gas, diesel, pompa panas)

* Pengeringan udara alami (cocok untuk iklim hangat dan produksi skala kecil)

Bagaimana pemasangan dan pelatihan peralatan ditangani?

Kami menyediakan:

* Panduan instalasi (video dan manual)

* Penyetelan di lokasi oleh insinyur luar negeri (jika berlaku)

* Dukungan teknis jarak jauh dan pelatihan operasi

Apakah tegangan mesin dapat disesuaikan?

* Waktu pengiriman: Biasanya 25–45 hari kerja, tergantung konfigurasi dan jumlah pesanan.

* Purna jual: Garansi 1 tahun, dukungan teknis seumur hidup, dan suku cadang dikirim bersama peralatan.

Apakah tegangan mesin dapat disesuaikan?

Ya, kami dapat menyesuaikan voltase sesuai standar negara, seperti 220V / 380V / 415V, 50Hz atau 60Hz, fase tunggal atau tiga fase.