Prix de la ligne de production de machine à mouler des plateaux à œufs

Si vous souhaitez établir une entreprise de fabrication de plateaux à œufs, voici la ligne de production complète de machines à mouler des plateaux à œufs pour vous. Et le prix sera basé sur votre capacité, vos conditions locales, et plus encore. Nous vous recommandons la bonne machine à plateaux à œufs et le séchoir pour réduire vos coûts d'investissement. De plus, vous obtiendrez les meilleurs devis de notre part. N'hésitez pas à nous contacter dès maintenant.

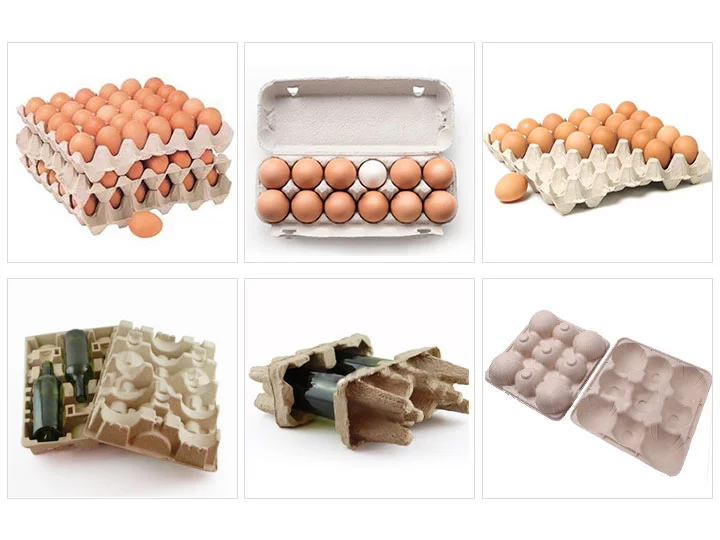

Machine de moulage de plate à œufs pour votre activité

Notre machine à mouler des plateaux d'œufs est disponible en différents modèles avec des capacités de production allant de 1000 pièces par heure à 8000 pièces par heure. En général, pour des capacités de production inférieures à 3000 pièces par heure, il n'est pas recommandé d'utiliser une machine à sécher les plateaux d'œufs.

Au lieu de cela, la méthode de séchage par air est recommandée car le coût de séchage est relativement élevé. L’introduction d’un équipement de séchage augmenterait les coûts, et avec des volumes de production plus faibles, la rentabilité pourrait être limitée.

Pour des capacités de production dépassant 3000 pièces par heure, bien que la marge bénéficiaire puisse diminuer, le volume de production plus élevé compense. Par conséquent, même si le profit par pièce peut diminuer légèrement, la rentabilité globale reste favorable.

Combien coûte une ligne de production complète de plate à œufs ?

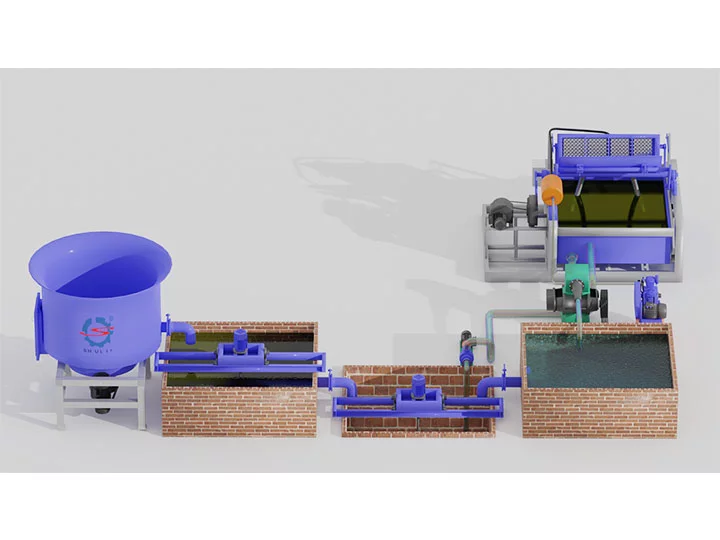

Le coût d'une ligne de production de plateaux d'œufs varie en fonction des conditions environnementales locales et de l'espace d'usine disponible. Établir une ligne de production complète de plateaux d'œufs implique divers équipements, y compris une machine à fabriquer de la pâte, une machine à mouler des plateaux d'œufs et un séchoir à plateaux d'œufs.

Le prix diffère pour chaque pièce d’équipement en raison des capacités de production variables – généralement, un équipement à plus haute capacité est assorti d’un prix plus élevé. De plus, le choix de la méthode de séchage influence le coût de l’investissement. Les processus de séchage peuvent nécessiter de l’électricité ou du charbon, tandis que le séchage à l’air élimine le besoin d’énergie supplémentaire.

Les conditions climatiques diffèrent énormément d’une région à l’autre; certaines zones présentent des températures élevées et peu de précipitations, ce qui rend le séchage à l’air adapté – c’est souvent le cas dans de nombreux pays africains où les températures sont constamment élevées. À l’inverse, les régions avec des précipitations fréquentes et une humidité élevée sont moins adaptées au séchage à l’air. Pour le coût détaillé, n’hésitez pas à nous contacter.

Ligne de moulage de plate à œufs en pulpe de papier

Pulpeur à papier :

Cette machine est responsable de la décomposition des matières premières en un mélange de pulpe en les combinant avec de l'eau.

Machine de moulage de plateaux à œufs :

Cet équipement utilise le mélange de pulpe pour former la forme et le design des plate à œufs, utilisant habituellement des moules avec différentes cavités.

Sèche-plateaux à œufs :

La machine de séchage ou le four applique de la chaleur pour éliminer l'humidité des plateaux à œufs moulés, garantissant qu'ils sont solides et prêts à l'emploi.

Équipement d'emballage :

Une fois séchés, les plateaux à œufs sont manipulés et emballés selon des besoins d'emballage spécifiques.