纸浆酒托制造机 | 酒包装托盘制造机

| 品牌 | 树立机械 |

| 型号 | SL系列 |

| 容量 | 1000-7000个/小时 |

| 功率 | 38-120千瓦 |

| 电压 | 380V, 50HZ |

| 尺寸 | 参考技术参数表 |

| 保修 | 12个月 |

您现在可以向我们的项目经理询问技术细节

纸浆酒托成型机是一种工业设备,旨在生产模压纸浆酒托。它使用真空成型、压制和干燥等工艺将纸浆塑造成各种托盘设计。

纸浆酒托是由废纸、纸箱和类似材料使用纸浆成型技术制造的环保包装材料。与传统泡沫包装相比,纸浆酒托更加环保,可生物降解,并且具有良好的缓冲性能,更加适合现代绿色包装的需求。

这款葡萄酒包装托盘制造机在现代绿色包装生产线中发挥着重要作用,特别适用于制作玻璃瓶的托盘,如葡萄酒、香槟和烈酒。

舒立提供7 种型号的纸浆模塑机,产能为1,000 至 7,000 件/小时,每年出口超过50 台。

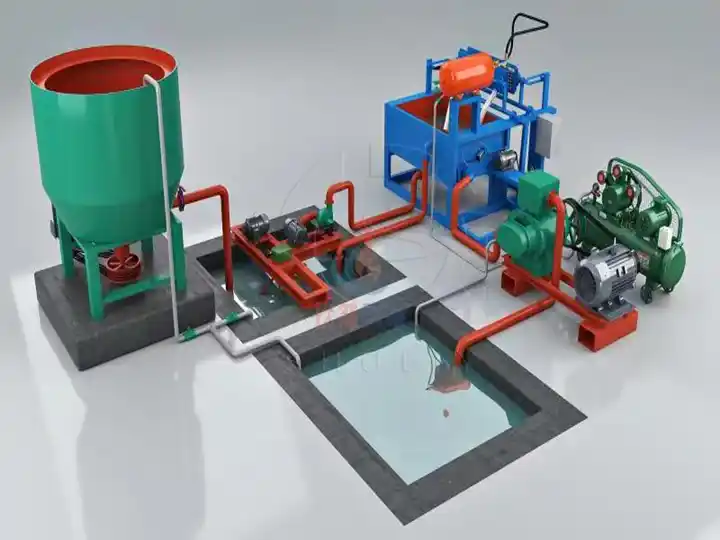

纸浆葡萄酒托盘制造机的主要结构

纸浆酒盒成型机主要包括制浆系统、成型系统、干燥系统和包装系统。

- 制浆系统: 这包括一个打浆机、水箱和搅拌机。它将废纸与水混合以制成光滑的浆料。它连接到一个浆料浓度控制装置。

- 成型系统: 这使用真空模具在负压下成型纸浆。模具由上下两部分组成,可以快速更换以适应不同的酒瓶托盘。成型驱动可以是液压或气动的。

- 干燥系统: 成型后,湿托盘在高温下干燥。有六种干燥方法可供选择:自然干燥、干燥炉、砖砌干燥室或多层金属干燥。这确保了托盘的尺寸稳定,表面光滑。

- 包装系统: 托盘可以通过堆垛机进行计数和堆叠,然后包装以便运输。

Shuliy纸浆葡萄酒托盘制造机的技术参数

| 型号 | 容量 | 功率 | 电压 | 重量 | 浆料使用 | 水使用 | 尺寸(毫米) |

| SL-1000-3X1 | 1000个/小时 | 38千瓦 | 380V, 50HZ | 2500千克 | 80千克/小时 | 160千克/小时 | 2600*2200*1900 |

| SL-1500-4X1 | 1500个/小时 | 38千瓦 | 380V, 50HZ | 3000千克 | 120千克/小时 | 240千克/小时 | 2800*2200*1900 |

| SL-2500-3X4 | 2500个/小时 | 55千瓦 | 380V, 50HZ | 4000千克 | 200千克/小时 | 400千克/小时 | 2900*1800*1800 |

| SL-3000-4X4 | 3000件/小时 | 60千瓦 | 380V, 50HZ | 4800千克 | 240千克/小时 | 480千克/小时 | 3250*1800*1800 |

| SL-4000-4X8 | 4000件/小时 | 95千瓦 | 380V, 50HZ | 7000千克 | 320千克/小时 | 640千克/小时 | 3250*2300*2500 |

| SL-5000-5X8 | 5000件/小时 | 95千瓦 | 380V, 50HZ | 8000千克 | 400千克/小时 | 800千克/小时 | 3700*2300*2500 |

| SL-7000-6X8 | 7000件/小时 | 120千瓦 | 380V, 50HZ | 10000千克 | 480千克/小时 | 960千克/小时 | 3200*2300*2500 |

以上是我们的标准模型供参考。如果您有更具体的要求,我们也可以根据您的需求定制机器。

纸浆酒托成型机是如何工作的?

与蛋托机类似,纸浆酒盒成型机采用纸浆成型技术。它遵循纸浆成型工艺,将纸浆注入模具。然后,通过真空吸力、热风干燥成型,形成具有特殊强度和设计的托盘。

主要工作步骤还包括:制浆 → 成型 → 干燥 → 包装。

Shuliy葡萄酒包装托盘制造机的优点

- 高自动化从制浆到成型、修剪和包装,整个过程是自动化的,节省了人工成本。

- 环保生产没有废水或气体排放。原材料可以再次回收,符合当地环境政策。

- 定制模具: 适用于不同瓶子尺寸和类型(如波尔多酒、香槟、烈酒瓶)。我们还可以根据您寄给我们的瓶子定制模具。

- 良好的表面光洁度: 托盘看起来光滑干净,非常适合高档葡萄酒礼品盒或展厅展示。您可以定制颜色、logo 压印或图案,以提升您的包装。

- 多种托盘选项: 可以生产1、2、6或12瓶的托盘。

- 稳定的性能: 精确控制成型压力、时间和模具配合,以确保一致的质量。与普通机器相比,它的运行时间可以长达2.5倍。

- 高精度模具系统使托盘更坚固、更稳定,具有良好的承重能力且没有翘边。托盘具有对称的支撑点,以提高性能。

- 可提供定制服务: 我们提供基于样品的设计、瓶子尺寸匹配、标志压印、颜色定制等服务,帮助您的品牌脱颖而出。我们可以提供一站式包装解决方案,配备托盘成型机。

- 提供完整的生产线和解决方案: 作为一家直接制造商,我们可以提供制浆机、空气压缩机、干燥机及其他设备。我们还提供合理的土地布局规划,以帮助降低您的劳动力成本。

纸浆酒托的类型有哪些?

| 类别 | 类型 |

| 按瓶容量 | 187毫升,375毫升,500毫升,700毫升,750毫升,1升,1.5升,3升/5升 |

| 按瓶数量 | 单瓶,双瓶,四瓶,六瓶,十二瓶 |

| 按结构 | 一体式,顶部和底部分开式,插入式 |

| 按成型工艺 | 干压成型,湿压成型 |

| 按用途 | 运输保护型,礼品盒展示型,出口型 |

为什么选择酒包装托盘制造机

它有广泛的应用:

- 葡萄酒制造商: 用于瓶装葡萄酒产品的内包装。

- 电子商务平台: 适合安全运输单瓶或多瓶葡萄酒。

- 礼品包装公司用于礼品酒盒或优质酒套装内的托盘。

- 出口贸易商: 符合欧盟、美国及其他国家的环保包装法规。

- 超市和零售店: 用于组合包装,使展示和销售更加方便。

与其他包装材料相比的优势:

| 项目 | 纸浆酒托 | 塑料泡沫托盘 | 瓦楞纸插入物 |

| 环保 | 可生物降解,环保 | 不可生物降解的 | 可回收的 |

| 保护 | 强 | 非常强 | 中等 |

| 成本 | 中等 | 更高 | 更低 |

| 定制化 | 高 | 中等 | 中等 |

| 外观 | 良好(湿压效果更佳) | 差 | 中等 |

纸浆葡萄酒托盘制造机的成品

我们经常生产的纸浆酒托如下所示。然而,我们还有许多其他模具选项可供选择。如果您感兴趣,请随时与我们联系!

纸浆酒托制造机的运输展示

以下是我们的一些运输照片。您可以查看我们的包装。