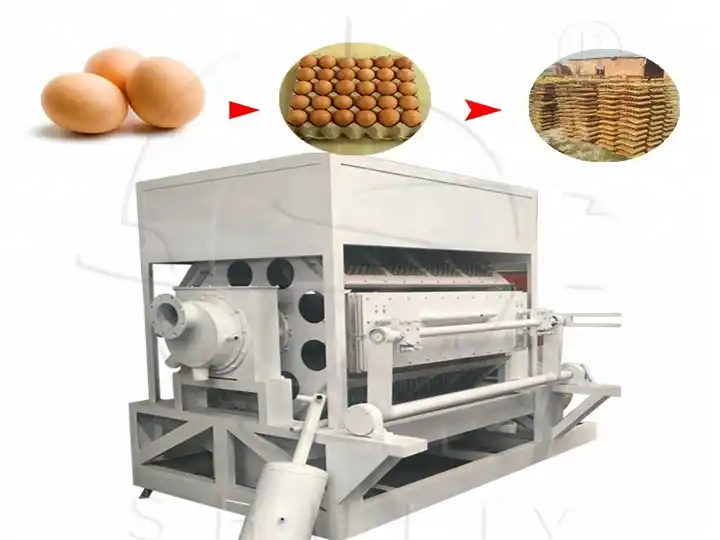

Máy làm hộp trứng

| Mô hình | Dòng SL |

| Dung lượng | 1000-7000 cái/giờ |

| Công suất | 38-120kw |

| Điện áp | 380V, 50HZ |

| Kích thước | Bảng tham số kỹ thuật tham khảo |

| Thời gian bảo hành | 12 tháng |

Bạn có thể hỏi các quản lý dự án của chúng tôi về chi tiết kỹ thuật

Máy làm khay trứng là cỗ máy quan trọng nhất trong dây chuyền sản xuất khay trứng. Máy này áp dụng nguyên lý tạo hình ép nóng. Bột giấy biến đổi thành huyền phù sợi được phủ đều lên bề mặt khuôn, sau đó được ép để tạo thành khay trứng.

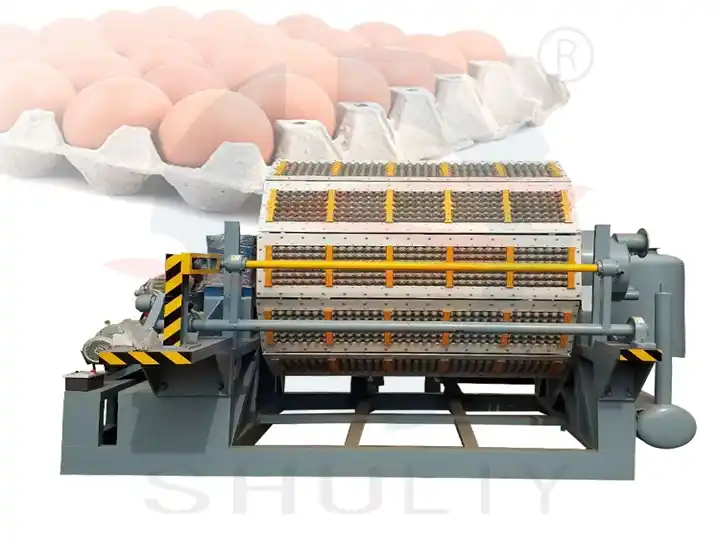

Máy làm khay trứng có thể chia thành máy làm khay trứng một mặt và máy làm khay trứng nhiều mặt. Máy làm khay trứng nhiều mặt cũng có thể chia thành máy làm khay trứng 4 mặt, máy làm khay trứng 8 mặt và máy làm khay trứng 12 mặt.

Máy làm khay trứng Shuliy có công suất sản xuất 1.000–7.000 chiếc/giờ, đáp ứng nhu cầu của cả doanh nghiệp nhỏ và lớn. Theo yêu cầu của bạn, chúng tôi có thể cung cấp cấu hình dây chuyền sản xuất bán tự động hoặc hoàn toàn tự động.

Cho đến nay, chúng tôi đã cung cấp máy làm khay trứng cho hơn 50 quốc gia và khu vực, bao gồm Tanzania, Ả Rập Saudi, Mexico, Chad, Uzbekistan, Cameroon, Zambia và Philippines. Sản phẩm của chúng tôi đã được khách hàng trên toàn thế giới đánh giá cao.

Cấu trúc của máy làm khay trứng

Máy làm khay trứng chủ yếu bao gồm động cơ tạo hình kiểu trống, tấm khuôn tạo hình, tấm khuôn chuyển, bơm chân không, máy nén khí, bình chứa, thân máy và một số bộ phận khác.

Động cơ tạo hình kiểu trống

- Chức năng: Cung cấp năng lượng ổn định để truyền động trống tạo hình, đảm bảo bột giấy hấp thụ đều trên khuôn.

- Dữ liệu: Dải công suất 7,5–15 kW, tốc độ lên đến 1440 vòng/phút, hỗ trợ công suất sản xuất 1000–7000 chiếc/giờ.

- Điểm mấu chốt: Công suất và tốc độ động cơ trực tiếp quyết định sản lượng và độ đồng đều của khay.

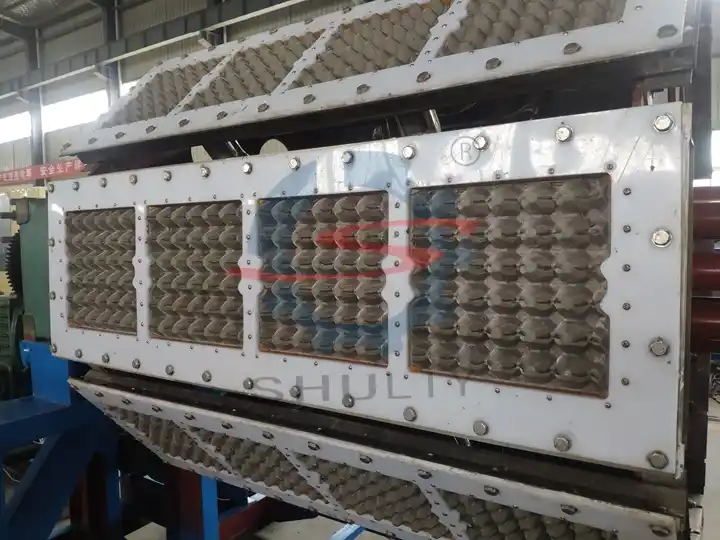

Tạo hình một tấm khuôn

- Chức năng: Tiếp xúc với bột giấy và sử dụng lực hút chân không để tạo hình ban đầu cho khay trái cây.

- Dữ liệu: Độ chính xác khuôn trong khoảng ±0,05 mm; độ dày khay 1,0–3,0 mm; một tấm khuôn có thể tạo hình 2–12 khay mỗi chu kỳ.

- Điểm mấu chốt: Độ chính xác bề mặt ảnh hưởng đến độ mịn và khả năng chịu tải của khay. Khuôn thép không gỉ chất lượng cao có tuổi thọ hơn 1.000.000 chu kỳ tạo hình.

Máy nghiền bột giấy

- Chức năng: Phá vỡ giấy vụn hoặc sợi thực vật thành bột bằng cách phân tán, tách rời và đồng nhất sợi, cung cấp nguyên liệu đồng đều để tạo hình khay.

- Dữ liệu: Nồng độ b pulp 3–5%; Hiệu quả tách sợi ≥ 95%; tỷ lệ loại bỏ tạp chất lên đến 90%; độ dài sợi phù hợp 0.2–1.5 mm.

- Điểm chính: Đảm bảo độ đồng đều cao của pulp, nâng cao độ bền của khay bằng 20–30% và giảm lỗi độ dày xuống còn ±0.2 mm.

Bơm chân không

- Chức năng: Cung cấp áp suất âm để hút sợi bột giấy lên bề mặt khuôn.

- Dữ liệu: Khả năng bơm 100–300 m³/h; độ chân không -0,06 đến -0,09 MPa.

- Điểm mấu chốt: Mức chân không cao hơn cải thiện mật độ sợi và độ bền khay.

Máy nén khí

- Chức năng: Cung cấp khí nén để tháo khuôn, đảm bảo khay tách ra nhanh chóng và hoàn toàn.

- Dữ liệu: Áp suất vận hành 0,6–0,8 MPa; lưu lượng khí 1–3 m³/phút.

- Điểm mấu chốt: Áp suất khí ổn định làm giảm tỷ lệ vỡ và tăng hiệu quả.

Bình chứa

- Chức năng: Lưu trữ khí nén và ổn định áp suất khí để hoạt động liên tục.

- Dữ liệu: Thể tích bình 0,3–1,0 m³; áp suất đầu ra ổn định 0,6–0,8 MPa.

- Điểm mấu chốt: Ngăn chặn việc khởi động máy nén thường xuyên và kéo dài tuổi thọ hệ thống.

Thân máy

- Chức năng: Chứa động cơ, khuôn, đường ống và hệ thống điều khiển, đảm bảo sự ổn định tổng thể của máy.

- Dữ liệu: Được chế tạo từ thép carbon hoặc thép không gỉ; được thiết kế để hoạt động liên tục 24/7.

- Điểm mấu chốt: Cấu trúc chắc chắn đảm bảo tuổi thọ cao (≥10 năm).

Các bộ phận phụ trợ khác

- Hệ thống đường ống: Kết nối bơm chân không, máy nén và khuôn; đường kính ống Φ25–Φ50 mm, đảm bảo lưu thông khí nhanh.

- Hệ thống điều khiển điện: Tự động hóa PLC với độ chính xác thời gian ±0,5 giây, cung cấp khởi động/dừng một nút, đếm sản phẩm và cảnh báo lỗi.

Máy làm khay trứng hoạt động như thế nào?

- Cho nguyên liệu vào máy nghiền, thêm một lượng nước thích hợp, và tạo ra một hỗn hợp sợi sau một thời gian khuấy lâu.

- Bơm nước sẽ hút bột giấy đã điều chỉnh vào bể chứa nước của máy tạo khay trái cây.

- Bột giấy được hấp thụ vào khuôn hình thành bằng hệ thống chân không, và nước thừa từ bùn được chuyển trở lại bể chứa thông qua hệ thống hấp thụ chân không để tái sử dụng.

- Dưới tác động của máy nén khí, khuôn tạo hình và khuôn chuyển sẽ được kết hợp để ép bột giấy thành hộp trứng.

- Khay trứng đã được ép sẽ được chuyển ra ngoài bằng khuôn chuyển để vào quy trình sấy tiếp theo.

Cách đặt tên máy làm khay trứng

Giới thiệu mẫu máy làm khay trứng (lấy SL-5 * 8 làm ví dụ)

- SL: Viết tắt tên công ty của chúng tôi

- 5: Số lượng khuôn trên tấm khuôn

- 8: 8 tấm khuôn

Phân loại máy làm khay trứng

Tiếp theo, tôi sẽ giới thiệu các máy làm khay trứng theo thứ tự là máy làm khay trứng một mặt và máy làm khay trứng nhiều mặt, cùng với các thông số kỹ thuật của chúng.

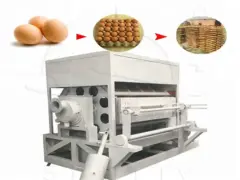

Máy tạo hình hộp trứng đơn mặt

Giới thiệu

Máy làm khay trứng một mặt còn được gọi là máy tạo khay trái cây một mặt, và sản lượng khoảng 1000-2000 chiếc mỗi giờ. Máy này chỉ có một tấm khuôn tạo hình, nên còn được gọi là máy làm khay trứng kiểu lật. Mẫu này hiện là một trong những mẫu phổ biến nhất và lý tưởng cho các nhà đầu tư nhỏ và vừa cũng như người mới bắt đầu.

Thông số kỹ thuật

| Mô hình | Dung lượng | Giấy nước | Tiêu thụ nước | Tiêu thụ điện | Công nhân |

| SL-3*1 | 1000-1500 cái/giờ | 120kg/giờ | 300kg/giờ | 32kw/giờ | 3-4 |

| SL-4*1 | 1500-2000 cái/giờ | 160kg/giờ | 380kg/giờ | 45kw/giờ | 3-4 |

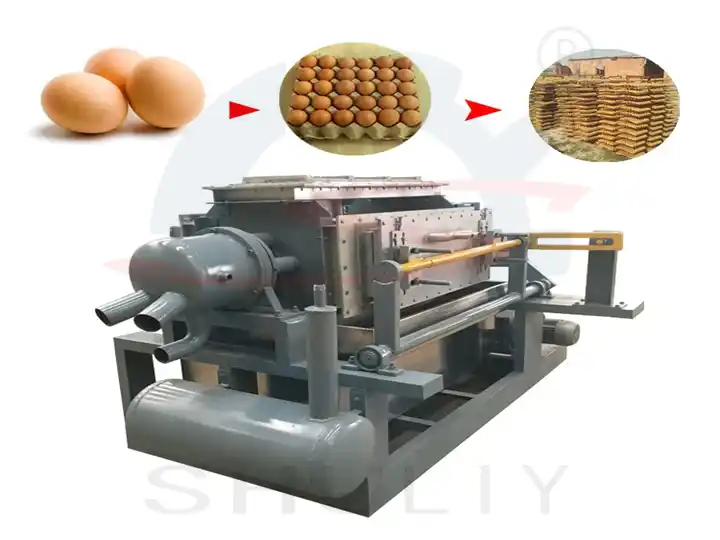

Máy làm khay trứng 4 mặt

Giới thiệu

Máy tạo khay trứng bốn mặt chủ yếu bao gồm bốn tấm khuôn với góc 90 độ. Tạo thành một khối lập phương quay. Do khả năng sản xuất quay của máy, nó tiết kiệm thời gian chờ và tăng hiệu quả công việc. Máy có thể sản xuất 2000-3500 khay trứng mỗi giờ.

| Mô hình | Dung lượng | Giấy nước | Tiêu thụ nước | Tiêu thụ điện | Công nhân |

| SL-3*4 | 2000-2500 cái/giờ | 200kg/giờ | 450kg/giờ | 58kw/giờ | 4-5 |

| SL-4*4 | 3000-3500 cái/giờ | 280kg/giờ | 560kg/giờ | 78kw/giờ | 4-5 |

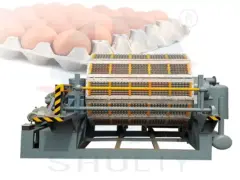

Máy làm khay trứng 8 mặt

Giới thiệu

Máy làm khay trứng này có tám tấm khuôn với góc 45 độ để hoạt động liên tục. Cánh tay chuyển của máy có thể thực hiện công việc chuyển động tịnh tiến 90 độ với hiệu suất cao. Máy này là máy có công suất lớn. Sản lượng có thể đạt 4000-5000 khay trứng mỗi giờ.

Thông số kỹ thuật

| Mô hình | Dung lượng | Giấy nước | Tiêu thụ nước | Tiêu thụ điện | Công nhân |

| SL-4*8 | 4000chi/giờ | 320kg/giờ | 600kg/giờ | 80kw/h | 5-6 |

| SL-5*8 | 5000 cái/giờ | 400kg/giờ | 750kg/giờ | 85kw/h | 3-4 |

Máy làm khay trứng 12 mặt

Giới thiệu

Năng suất của máy làm khay trái cây hiện tại là cao nhất. Có 12 tấm khuôn liên tục quay để làm khay trứng.

Thông số kỹ thuật

| Mô hình | Dung lượng | Giấy nước | Tiêu thụ nước | Tiêu thụ điện | Công nhân |

| SL-5*12 | 6000 cái/giờ | 480kg/h | 900 kg/giờ | 90kw/h | 3-4 |

| SL-6*12 | 8000 cái/giờ | 640kg/h | 1040kg/h | 100kw/h | 3-4 |

Thị trường ứng dụng của máy làm hộp trứng

Sản phẩm cuối cùng của máy làm khay trứng chủ yếu liên quan đến khuôn, và các sản phẩm khác nhau có thể được sản xuất bằng cách thay thế các khuôn khác nhau. Hiện tại, máy này chủ yếu được sử dụng trong sản xuất khay trứng, khay rượu, khay táo, giá đỡ khuôn đồ chơi, bao bì linh kiện điện tử, và nhiều thứ khác. Nó có chức năng chống sốc và đệm tốt, và có thể tránh va chạm trong quá trình vận chuyển.

Dây chuyền sản xuất máy làm khay trứng

Là nhà máy sản xuất máy làm khay trứng, chúng tôi cung cấp dây chuyền sản xuất khay trứng hoàn chỉnh, bao gồm các lựa chọn bán tự động và hoàn toàn tự động. Chúng tôi cũng có thể thiết kế bố trí và lắp đặt máy theo kế hoạch nhà máy của bạn.

Tại sao chọn máy làm hộp trứng Shuliy?

- Tiết kiệm chi phí lao động. Sản xuất cơ khí thay vì lao động thủ công có thể tiết kiệm rất nhiều chi phí lao động.

- Ứng dụng rộng rãi và thay thế khuôn đơn giản. Các sản phẩm khác nhau có thể được sản xuất bằng cách thay đổi khuôn, có thể được sử dụng rộng rãi trong đóng gói trái cây, rượu, thiết bị y tế, linh kiện điện tử và các lĩnh vực khác.

- Chất lượng tốt. Khoảng cách giữa các khuôn có thể ảnh hưởng đến độ kín của sản phẩm cuối cùng. Máy làm hộp trứng được trang bị thép không gỉ, khoảng cách giữa các khuôn không vượt quá 2mm.

- Thân thiện với môi trường. Nguyên liệu thô là giấy phế liệu, và nước trong quá trình sản xuất có thể được tái chế, do đó hầu như không phát sinh nước thải và không gây gánh nặng cho môi trường.

- Dịch vụ trước và sau bán hàng tốt. thời gian bảo hành dài của máy làm khay trái cây.