卵トレイ乾燥室で卵トレイを乾燥させる方法は?

卵トレイ乾燥室は、レンガ造りの乾燥室とも呼ばれ、湿った成形卵トレイを完全に乾燥させるために使用されます。これにより、変形、亀裂、カビの発生を防ぎ、中型および大型の卵トレイ生産ラインにとって効率的で安定した年間乾燥ソリューションを提供します。

この記事では、乾燥室の仕組み、段階的な乾燥プロセス、そしてなぜ多くのパルプ成形工場で好まれる乾燥方法になったのかを説明します。

卵トレイ乾燥室とは?

卵トレイ乾燥室は、連続熱風循環を利用した密閉された断熱乾燥室で、濡れた卵トレイから水分を除去します。自然日光乾燥と比べて、効率が高く、品質が安定し、天候に左右されずに運用できます。

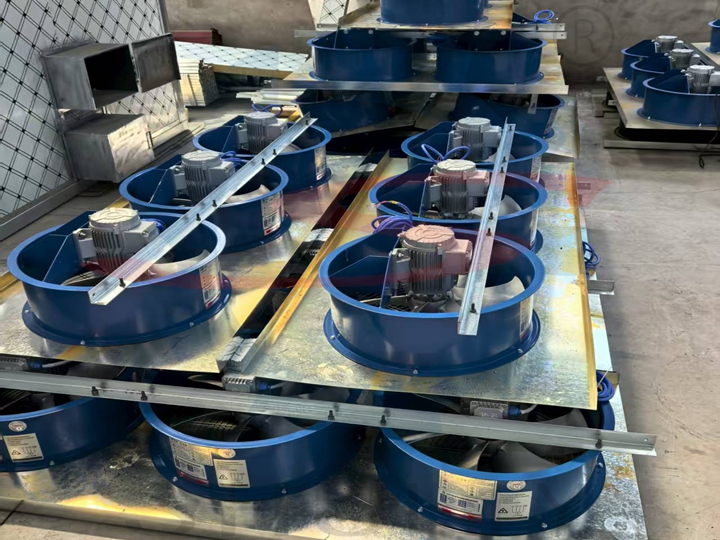

構造は主に材料室と加熱室を含みます。主要な設備には熱源、換気、湿気排出システム、温湿度制御システムがあります。主な特徴は、両面熱風供給、より均一な乾燥、内部レイアウトの工夫、強力な空気流システム、柔軟な温湿度制御です。

材料室:トレイはラックまたはパレットに置かれます。鋼製の空気絶縁板が材料室と加熱室を隔てます。

加熱室:この室には加熱装置があり、熱風を生成します。運転中はブロワーが熱風を材料室に送ります。

熱風循環:循環ファンが熱風をダクトに押し込みます。空気はトレイラックの小さな穴を通じて材料室に入り、左右の空気供給設計により均一な乾燥を実現します。

加熱オプション:天然ガス、石炭、バイオマスペレット、電気加熱、または空気エネルギー加熱が使用可能です。

換気&湿気排出システム:加熱室と材料室の間で空気を循環させ、適切な空気交換を確保します。

温度&湿度制御システム:センサー、コントローラー、アクチュエーターを通じて乾燥条件を監視・調整します。加熱装置を制御して自動乾燥を実現します。

卵トレイ乾燥機はどのように動作しますか?

乾燥室は循環熱風を使用して濡れた卵トレイを迅速かつ均一に乾燥します。工程は次のステップを含みます:

濡れた卵トレイの積み込み

新しく成形された湿ったトレイは、ステンレス鋼またはプラスチックの乾燥トレイの上に置かれます。

作業員は荷物を積んだ台車を乾燥室に押し込み、良好な空気の流れを確保するためにトレイ間に適切な間隔を保ちます。

加熱と熱風循環

扉が閉じられると、熱源が空気を暖めます(通常80〜120°C)。

強力な循環ファンが熱風を乾燥室の隅々に届け、均一な乾燥を実現します。

水分蒸発と排気

熱風がトレイの表面を横切り、湿気を蒸発させます。

湿った空気は排気口から排出され、新鮮な空気が入り、「空気供給–加熱–湿気除去」サイクルを維持します。

乾燥完了

乾燥プロセスは通常、容量、トレイの厚さ、温度に応じて20〜30分かかります。

トレイが必要な乾燥度に達したら、台車を取り外し、梱包またはホットプレス成形に送ります。

技術パラメータ(参考)

| モデル | 寸法(mm) | 乾燥クルー | 乾燥材料の量 (times/kg) |

| SL-2 | 4000*1860*2500 | 2 | 300-600 |

| SL-4 | 6000*1860*2500 | 4 | 500-1000 |

| SL-6 | 7200*2300*2500 | 6 | 800-1500 |

| SL-8 | 8500*2300*2500 | 8 | 1000-2000 |

| SL-10 | 10000*2300*2500 | 10 | 1200-2500 |

| SL-12 | 8500*3300*2500 | 12 | 2500-4000 |

| SL-18 | 8500*5000*2500 | 18 | 4000-6500 |

| SL-24 | 12000*5000*2500 | 24 | 5000-8000 |

卵トレイ乾燥室を使用する利点

1. 高効率、天候に左右されない

天日乾燥は天候に左右されますが、乾燥室は連続運転が可能で、生産能力を大幅に向上させます。

2. 均一な乾燥と安定した製品品質

熱風循環により、すべてのトレイが均一に乾燥し、変形や亀裂のリスクを低減します。

3. 柔軟な熱源

地元の価格に基づいてエネルギータイプを選択:天然ガス、ディーゼル、石炭、電気、またはヒートポンプ。

4. 大容量、拡張容易

乾燥能力は、部屋の長さを延長するだけで簡単に向上させることができます。アップグレードは便利でコスト効率的です。

5. 金属連続乾燥ラインより投資コストが低い

自動チェーンタイプの金属乾燥機と比較して、乾燥室は構造が簡単でコストも低く、予算が限られた工場に最適です。

卵トレイ乾燥室を正しく操作する方法は?

最良の乾燥結果を得るために、次のガイドラインに従ってください:

- トレイ間の間隔を一定に保つ:適切な空気流通のためにトレイ間の隙間を均一にしてください。

- 過負荷を避ける:一度にあまり多くのトレイを積み重ねないでください。

- 乾燥室の予熱:トレイを積み込む前にキャビンを暖めます。

- 安定した温度と空気流を維持:運転中は熱とファンの設定を一定に保ちます。

- ファンと空気ダクトを定期的に清掃:ほこりの蓄積を防ぎ、効率的な乾燥を確保します。

- 湿度に応じて排気を調整:湿気レベルに従って通気口を開閉します。

- 常に公式マニュアルに従って乾燥室を操作してください。

なぜShuliyを選ぶのか 卵トレイ乾燥機?

Shuliyはパルプ成形装置で20年以上の経験を持ち、さまざまな卵トレイ乾燥ソリューションを提供しています。生産能力、工場レイアウト、燃料タイプに基づいてカスタマイズ可能です。

私たちの利点:

- 高断熱の乾燥室構造、省エネルギーと材料節約

- より均一な乾燥のための最適化された空気循環

- 完成したトレイは変形や亀裂の可能性が低くなります

- 主要コンポーネントには1年間の保証付き

- CE、ISO9001などの業界認証

- 60か国以上に輸出されたプロジェクトで実績あり

小規模工場や大規模生産ライン向けに、Shuliyは効率的で安定したコスト効果の高い乾燥ソリューションを提供できます。