Lini Produksi Tray Cangkir Kopi

| Kapasitas Produksi | 1000-7000pcs/jam |

| Muatan Bahan Pulp | 1–1,5 kg per tempat |

| Tekanan Vakum | –0,04 hingga –0,06 MPa |

| Temperatur Penekanan Panas | 180–250 °C |

| Metode Pengeringan | Sirkulasi udara panas atau pengering tungku bata |

| Pasokan Daya | Dapat Disesuaikan |

| Jenis Cetakan | Tempat 2-satu, tempat 4-satu, tempat 6-satu, bentuk khusus |

| Garansi | 12 bulan |

Anda sekarang dapat meminta detail teknis kepada manajer proyek kami

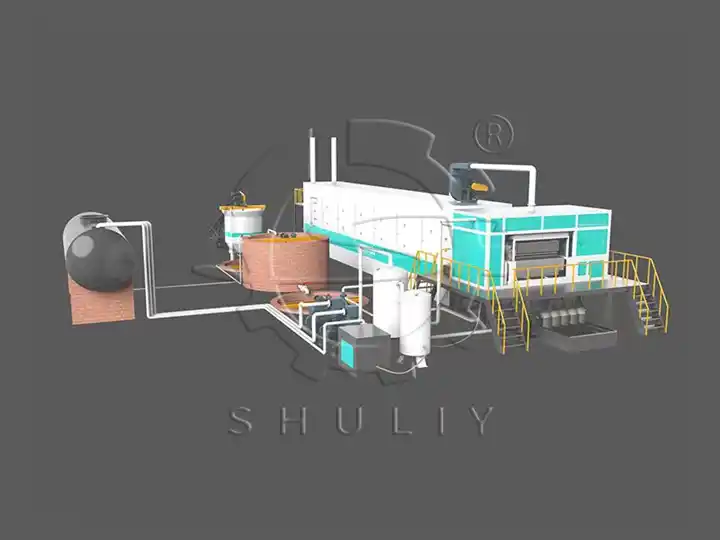

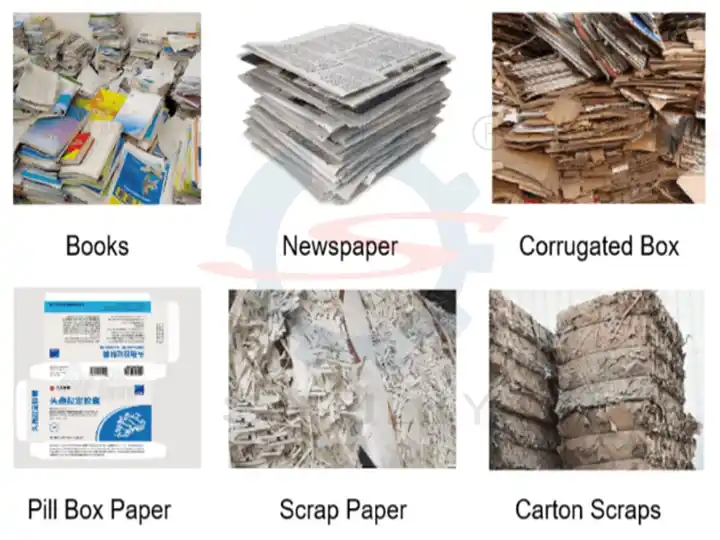

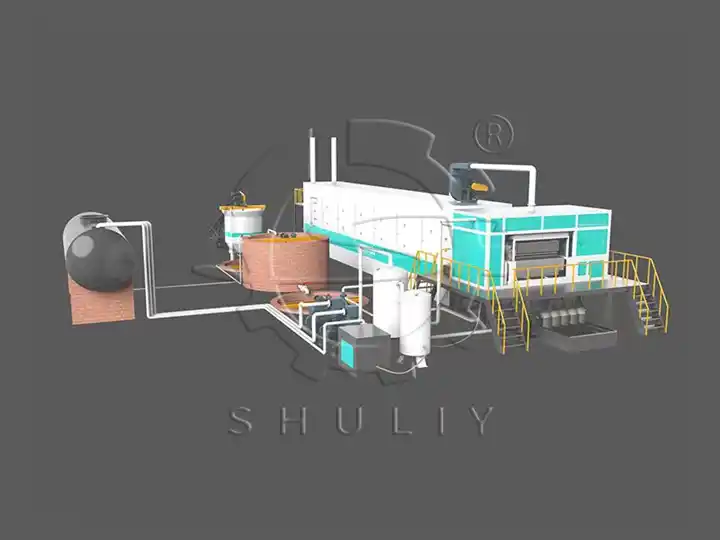

Garis produksi tempat cangkir kopi sekali pakai adalah sistem otomatis penuh. Menggunakan kertas limbah, karton lama, dan papan pulp sebagai bahan baku, dan melalui empat tahap utama: penggilingan, pencetakan, pengeringan, dan penekanan panas, untuk menghasilkan tempat cangkir pulp yang ramah lingkungan dan dapat terurai.

Garis produksi tersedia dalam tipe semi-otomatis dan otomatis penuh, dengan 7 model tersedia, dan kapasitas 1.000–7.000 potong per jam.

Garis tempat cangkir kopi Shuliy dapat membuat satu, 2-satu, atau 4-satu tempat pulp biodegradable dalam satu proses pencetakan, banyak digunakan untuk layanan takeout.

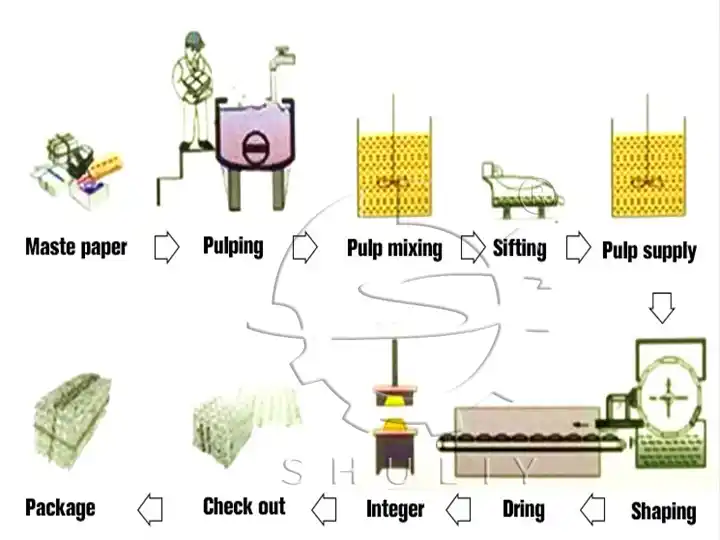

Prinsip Kerja Garis Produksi Tempat Cangkir Kopi

Tempat cangkir kopi biasanya dibuat menggunakan teknologi pencetakan pulp. Prinsip utamanya adalah mengubah kertas limbah atau bahan serat lain menjadi pulp, kemudian membentuk, mengeringkan, dan menekan panas untuk menghasilkan tempat cangkir kopi yang dapat terurai dan ramah lingkungan.

Parameter Teknis

| Barang | Spesifikasi |

|---|---|

| Kapasitas Produksi | 1.000–7.000 potong/jam |

| Muatan Bahan Pulp | 1–1,5 kg per tempat |

| Tekanan Vakum | –0,04 hingga –0,06 MPa |

| Temperatur Penekanan Panas | 180–250 °C |

| Metode Pengeringan | Sirkulasi udara panas atau pengering tungku bata |

| Pasokan Daya | Dapat Disesuaikan |

| Jenis Cetakan | Tempat 2-satu, tempat 4-satu, tempat 6-satu, bentuk khusus |

Parameter Teknis Mesin Cetak Tempat Cangkir Kopi Terlaris

| Model | Kapasitas | Daya | Tegangan | Berat | Penggunaan Pulp | Penggunaan Air | Ukuran(mm) |

| SL-1000-3X1 | 1000pcs/jam | 38kw | 380V,50HZ | 2500kg | 80kg/jam | 160kg/jam | 2600*2200*1900 |

| SL-1500-4X1 | 1500pcs/jam | 38kw | 380V,50HZ | 3000kg | 120kg/jam | 240kg/jam | 2800*2200*1900 |

| SL-2500-3X4 | 2500pcs/jam | 55kw | 380V,50HZ | 4000kg | 200kg/jam | 400kg/jam | 2900*1800*1800 |

| SL-3000-4X4 | 3000pcs/jam | 60kw | 380V,50HZ | 4800kg | 240kg/jam | 480kg/jam | 3250*1800*1800 |

| SL-4000-4X8 | 4000pcs/jam | 95kw | 380V,50HZ | 7000kg | 320kg/jam | 640kg/jam | 3250*2300*2500 |

| SL-5000-5X8 | 5000pcs/jam | 95kw | 380V,50HZ | 8000kg | 400kg/jam | 800kg/jam | 3700*2300*2500 |

| SL-7000-6X8 | 7000pcs/jam | 120kw | 380V,50HZ | 10000kg | 480kg/jam | 960kg/jam | 3200*2300*2500 |

Bagaimana Membuat Tempat Cangkir Kopi dari Pulpa?

Penggilingan Pulpa

- Kertas limbah, kardus, atau pulp kertas daur ulang dimasukkan ke dalam mesin penggiling dengan jumlah air yang sesuai.

- Bahan baku dihancurkan dan diaduk untuk membentuk slurry pulp yang seragam dan halus.

- Bahan tambahan opsional dapat ditambahkan untuk meningkatkan kekuatan pencetakan atau kehalusan permukaan, mempersiapkan pulp untuk proses pencetakan berikutnya.

Pembentukan

Mesin cetak tempat cangkir kopi pulp menggunakan vakum untuk menarik pulp basah ke cetakan logam atau silikon. Cetakan berbentuk untuk 2-satu atau 4-satu. Vakum memastikan pulp tersebar merata membentuk bentuk awal tempat.

Pengeluaran dan Pra-Pengering

Tempat basah diangkat dari cetakan dan dikirim ke area pra-pengeringan untuk menghilangkan sebagian kelembapan, membuatnya lebih mudah ditangani.

Pengeringan dan Penekanan Panas

Sistem pengeringan (misalnya, pengering sabuk) menghilangkan sisa kelembapan untuk mencapai kekerasan yang diperlukan. Penekanan panas menghaluskan permukaan dan tepi tempat.

Bahan Ramah Lingkungan

Terbuat dari kertas limbah, pulp, atau bahan yang dapat diperbarui, tanpa plastik. Tempat ini dapat terurai secara hayati dan memenuhi standar lingkungan global, seperti sertifikasi EN13432 dari Eropa.

Keunggulan Garis Produksi Tempat Cangkir Pembawa Kopi

Otomatisasi Tinggi dan Efisiensi

- Secara otomatis menyelesaikan penggilingan, pencetakan, pengeringan, penekanan panas, dan pengemasan.

- Produksi kontinu memastikan output yang stabil dan efisiensi tinggi, ideal untuk produksi skala industri.

- Mengurangi biaya tenaga kerja dan meminimalkan kesalahan manusia.

Penghematan Energi dan Konsumsi Rendah

- Sistem pengeringan dan proses pencetakan yang dioptimalkan untuk penggunaan energi rendah dan efisiensi tinggi.

- Penggunaan energi yang efisien membantu mengurangi biaya produksi.

Berbagai Ukuran dan Variasi

- Dapat memproduksi tempat 2-satu, 4-satu, 6-satu, dan bentuk khusus.

- Cetakan dapat disesuaikan untuk menyertakan logo atau merek.

- Memenuhi berbagai ukuran cangkir dan permintaan pasar.

Kualitas Produk Tinggi

- Penekanan panas dan pengeringan membuat tempat kuat, halus, dan tahan lama.

- Kualitas produk stabil dengan tepi rapi yang tahan deformasi.

Peralatan Stabil dan Perawatan Mudah

- Peralatan yang dirancang dengan baik, tahan lama, dan mudah perawatan.

- Operasi stabil dengan downtime rendah, cocok untuk produksi terus-menerus dalam waktu lama.

Aplikasi Luas

- Cocok untuk kedai kopi, toko minuman, pabrik kemasan takeout, dan produsen kemasan ramah lingkungan.

- Garis semi-otomatis atau otomatis penuh tersedia untuk berbagai kapasitas produksi.

Jenis Garis Produksi Tempat Cangkir Kopi

Menurut penanganan bahan, garis dapat sepenuhnya otomatis atau semi-otomatis.

Garis Produksi Tempat Cangkir Kopi Semi-Otomatis

Alur kerja:

Pencampuran pulp → Pembentukan → Tempat tidur basah dipindahkan secara manual → Pengeringan → Pemanasan panas → Pemangkasan → Pengemasan

Metode Pengeringan:

Pengering tungku bata atau pengering sirkulasi udara panas

Garis Produksi Tempat Cangkir Kopi Otomatis Penuh

Alur kerja:

Penggilingan → Pembentukan → Pengeluaran otomatis → Pengeringan → Penekanan panas → Pemangkasan → Penumpukan otomatis & pengemasan

Seluruh proses tidak memerlukan penanganan manual. Jalur dikendalikan oleh sistem PLC; operator hanya perlu mengatur parameter di panel kontrol.

Bagaimana Memilih Mesin Cetak Tempat Cangkir Kopi yang Tepat?

- Skala Produksi dan Anggaran: Pabrik kecil dapat memilih model semi-otomatis; perusahaan besar disarankan menggunakan jalur otomatis penuh.

- Pasokan Bahan Baku: Pastikan sumber bahan kertas yang stabil.

- Spesifikasi Produk Jadi: Berbagai bentuk dan ketebalan baki memerlukan desain cetakan yang berbeda.

- Ruang Pabrik dan Pengaturan Energi: Faktor-faktor ini mempengaruhi pilihan sistem pengeringan.

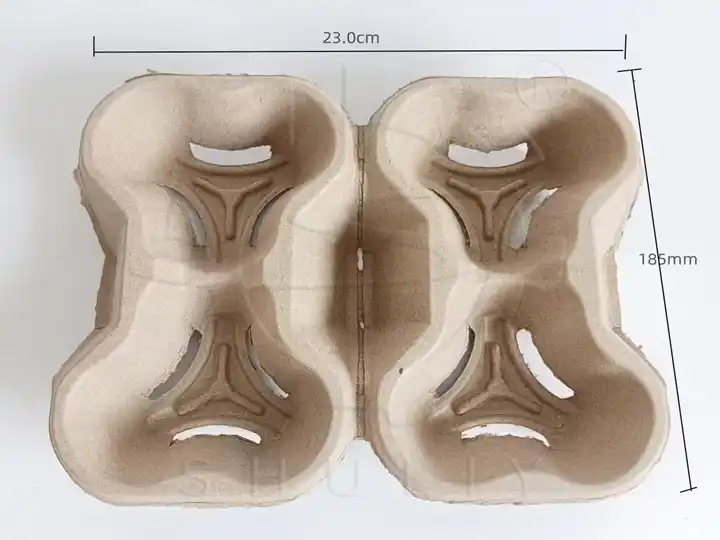

Jenis Tempat Cangkir Kopi yang Dapat Disesuaikan

Tempat Cangkir Kopi 2-satu

Tempat Cangkir Kopi 4-satu

Tempatan khusus dengan logo

Mengapa Memilih Shuliy?

- Pengalaman lebih dari 20 tahun dalam pembuatan peralatan pencetakan pulp

- Layanan satu atap: desain, produksi, dan instalasi

- Dukungan luar negeri lengkap: instalasi, tutorial video lengkap, dan bantuan teknis

- Solusi proses profesional dan pelatihan teknis

- Diekspor ke lebih dari 100 negara dengan lebih dari 95% kepuasan pelanggan

- Garis produksi otomatis penuh yang dapat disesuaikan dan hemat energi

- Dilengkapi dengan TUV, SGS, CE, dan ISO9001

- garansi 1 tahun

- Daya, tegangan, colokan, dan cetakan yang dapat disesuaikan