Machine à plateau à œufs 1 côté

| Modèle | SL-3*1, SL-4*1 |

| Capacité | 1000-1500pcs/h |

| Consommation d'eau | 300kg/h-380kg/h |

| Consommation de papier | 120-160kg/h |

| Consommation d'électricité | 32kw/h-45kw/h |

| Quantité de travailleurs | 3-4 |

| Garantie | 12 mois |

Vous pouvez maintenant demander des détails techniques à nos chefs de projet.

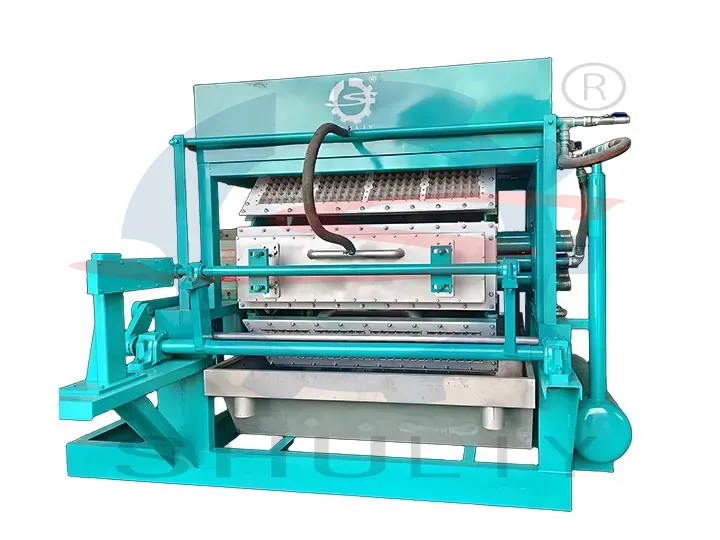

Le modèle courant est une machine à plateaux à œufs d'un côté, qui est une petite machine à fabriquer des plateaux à œufs. Shuliy propose le SL-1000-3X1 et le SL-1500-4X1, avec une capacité de 1000–1500 pièces/h.

Une machine à plateaux à œufs à 1 face désigne une machine de formation de plateaux à œufs dont les matrices de moulage sont installées sur un seul côté de la machine. Elle possède une face de travail unique, ce qui signifie que le processus de moulage de la pâte est effectué sur un seul côté à la fois. Ce type de machine est généralement utilisé pour la production à petite échelle, avec un rendement d'environ 1000–1500 pcs/h.

Cette machine a une conception simple, est facile à utiliser, prend peu de place et a un faible coût, de sorte que l'investissement peut être récupéré rapidement.

Zhengzhou Shuliy Machinery Co., Ltd est spécialisée dans les machines à plateaux à œufs. Nous avons plus de dix ans d'expérience dans la fabrication et l'exportation de machines à plateaux à œufs. Par conséquent, nous avons un service avant-vente et après-vente parfait. Nous sommes capables de produire une grande variété de plateaux à œufs et de fabriquer une variété de moules car le plateau à œufs peut être utilisé dans divers domaines.

Présentation de la machine à plateaux à œufs d'un côté la plus vendue

Cette machine est l'unité principale de l'ensemble du processus de production. C'est une machine à plateaux à œufs semi-automatique avec une faible capacité et une faible consommation d'énergie, ce qui la rend idéale pour la production à petite échelle. La machine forme plusieurs plateaux par cycle tout en consommant relativement peu d'eau, assurant un fonctionnement efficace.

La machine à plateaux à œufs se compose principalement d'un moule de transfert et d'un moule de formation. À l'aide d'une aspiration sous vide, la pâte adhère uniformément à la surface du moule pour former des plateaux à œufs humides, qui sont ensuite séchés pour devenir les produits finis.

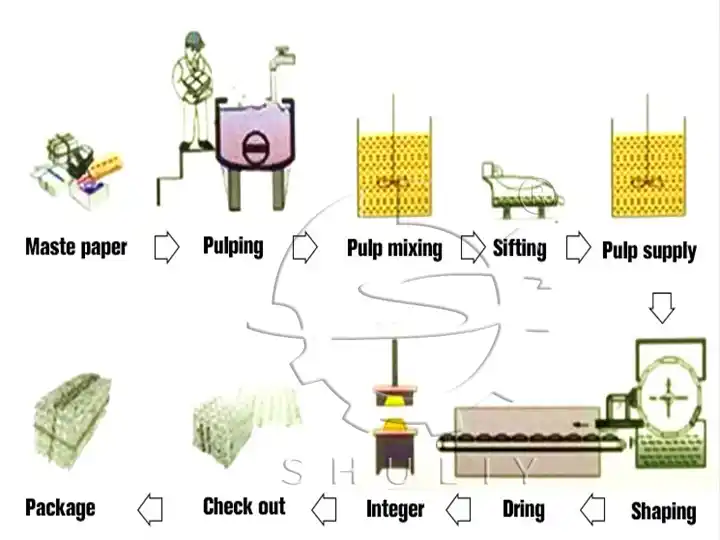

La principale matière première pour la machine à plateaux à œufs d'un côté est le papier de rebut. Le papier de rebut entre d'abord dans la machine à pulpe, où il est mélangé à de l'eau pour former de la pâte, puis transféré dans le réservoir de stockage de pâte. La pâte dans le réservoir de stockage est uniformément acheminée vers le réservoir d'alimentation en bouillie par un mélangeur, et après un nouveau mélange pour atteindre la consistance désirée, elle est envoyée à la machine de formage (généralement une machine à plateaux à œufs) pour le moulage, produisant des plateaux à œufs.

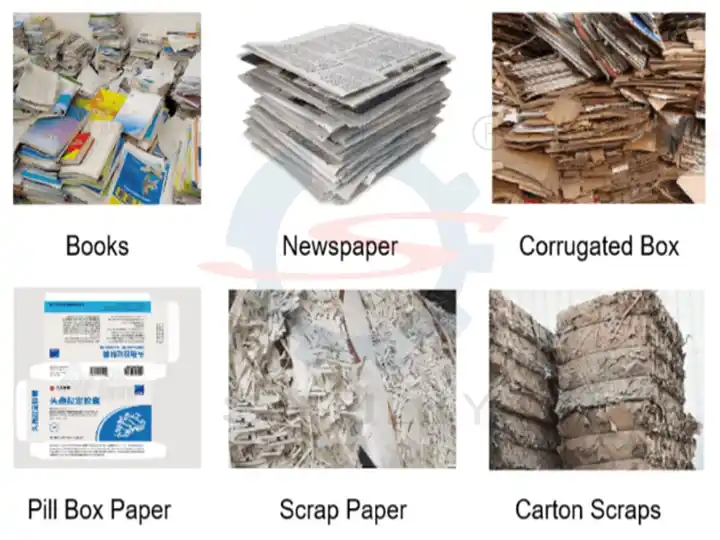

Matières premières pour la petite machine de fabrication de plateaux à œufs

Les matières premières de la petite machine de fabrication de plateaux à œufs sont généralement le papier journal usagé, le papier kraft, le papier ondulé, etc.

Dans le processus de production et de traitement, il s'agit principalement d'une réaction physique. Certains agents d'étanchéité peuvent être ajoutés selon les besoins du client. Après le séchage des produits, ces agents d'étanchéité sont pratiquement tous retenus dans le produit fini, et aucune teinture n'est rejetée. Par conséquent, les matières premières de la machine à plateaux à œufs sont très respectueuses de l'environnement.

Quels sont les avantages de la machine à plateaux à œufs d'un côté ?

Petite capacité, faible consommation d'énergie

- Rendement : Convient aux lignes de production à petite échelle avec 1000–1500 pièces/h.

- Puissance : La puissance totale de la machine est faible, généralement 32–45 kW, consommant 30 à 50 % d'électricité en moins que les machines à plusieurs côtés.

Économe en eau et respectueux de l'environnement

- Utilisation d'eau : Faible, environ 0,2–0,3 L par plateau.

- Utilise de la pâte de papier recyclé, respectueuse de l'environnement et économe en énergie. Elle peut être associée au séchage à l'air naturel, économisant complètement l'électricité et réduisant les émissions de carbone.

Formation à haute efficacité

- Le moulage par aspiration sur moule simple face garantit des plateaux uniformes avec des bords lisses.

- Matériau du moule : Alliage d'aluminium à haute résistance ou acier de première qualité, résistant à l'usure et à la corrosion, avec une durée de vie de plus de 10 ans.

Facilité d'utilisation et d'entretien

- Fonctionnement semi-automatique, une personne peut réaliser l'ensemble du processus de production.

- Les moules sont faciles à remplacer, permettant la production de plateaux à œufs, de plateaux à fruits ou de plateaux d'emballage industriels de différentes tailles.

Avantage de coût

- Faible investissement, adapté aux lignes de production petites et moyennes.

- Faible coût d'exploitation : moins de consommation d'électricité et d'eau, avec du papier recyclé. Idéal pour les startups ou les petits producteurs pour récupérer rapidement leur investissement.

Flexibilité et polyvalence

- La machine à plateaux à œufs d'un côté peut non seulement produire des plateaux à œufs, mais aussi, en changeant les moules, fabriquer des plateaux à fruits, des sous-verres et des plateaux d'emballage industriels.

- Cette conception multifonctionnelle est idéale pour répondre aux différentes demandes du marché ou aux produits saisonniers, maximisant l'utilisation de la machine et augmentant la rentabilité de la production.

Paramètres de la machine à plateaux à œufs d'un côté à vendre

| Modèle | Capacité | Consommation de papier | Consommation d'eau | Consommation d'électricité | Quantité de travailleurs |

| SL-1000-3X1 | 1000 pcs/h | 120kg/h | 300kg/h | 32kw/h | 3-4 |

| SL-1500-4X1 | 1500pcs/h | 160kg/h | 380kg/h | 45kw/h | 3-4 |

Shuliy propose non seulement des machines à plateaux à œufs à 1 face, mais aussi 4 faces, 8 faces, et 12 faces, répondant à diverses capacités et exigences de production. Nous offrons des services tels que des dessins personnalisés, des essais, la modification de la tension d'alimentation et la personnalisation des moules selon vos besoins, garantissant que les machines répondent pleinement à votre processus de production et à vos exigences opérationnelles.

Un côté contre plusieurs côtés

Voici un tableau pour montrer les différences entre eux :

| Fonctionnalité | Machine à plateaux à œufs 1 côté | Machine à plateaux à œufs multi-côtés (4/8/12 côtés) |

|---|---|---|

| Disposition des moules | Moules à un seul côté | Moules multi-côtés sur plateau tournant |

| Formation | Un côté à la fois | Moulage continu, multi-plateaux |

| Rendement | 1000–2000 pièces/h | Plusieurs milliers à plus de 10 000 pièces/h |

| Encombrement | Compact | Plus grand |

| Consommation d'énergie | Faible | Plus élevé au total, plus bas par plateau |

| Coût | Faible | Plus élevé |

| Idéal pour | Petites fermes, startups | Production commerciale à grande échelle |

Comparaison des avantages

| Fonctionnalité | Machine à plateaux à œufs 1 côté | Machine à plateaux à œufs multi-côtés (4/8/12 côtés) |

|---|---|---|

| Avantages | Faible investissement, facilité d'utilisation, faible consommation d'énergie, encombrement compact | Haut rendement, haute efficacité, adapté à la production à grande échelle |

| Idéal pour | Petites fermes, ateliers de démarrage | Grandes usines de plateaux à œufs, production industrielle |

| Flexibilité | Remplacement facile des moules, peut produire plusieurs types de plateaux | Idéal pour un seul produit, production en grands lots |

| Retour sur investissement | ROI rapide avec un petit investissement | Idéal pour un seul produit, production en grands lots |

Différence entre la machine à plateaux à œufs semi-automatique et entièrement automatique

La plus grande différence entre les modèles semi-automatiques et entièrement automatiques réside dans la méthode de séchage. Parce que la machine à plateaux à œufs semi-automatique a une petite capacité, la méthode de séchage peut adopter le séchage naturel. Au contraire, le rendement des machines entièrement automatiques est important, de sorte que les plateaux à œufs doivent être séchés dans le séchoir. Le séchage naturel prend du temps et est lent, ce qui ne convient pas à la production à grande échelle. Pour la production entièrement automatique, vous pouvez choisir une ligne de séchage métallique à une couche ou une ligne de séchage métallique à plusieurs couches pour sécher le plateau à œufs.

Méthode de séchage de la petite machine de fabrication de plateaux à œufs

En raison de la petite capacité de cette machine à plateaux à œufs d'un côté, la méthode de séchage peut être choisie comme séchage naturel. Certains débutants se lancent dans cette activité, mais ont peu de fonds, ils peuvent donc choisir le séchage naturel pour contrôler les coûts. Habituellement, le plateau à œufs peut être séché au soleil en une journée.

De plus, la température ambiante doit être supérieure à 38℃. Ce type de méthode de séchage permet également d'économiser beaucoup d'électricité. Bien sûr, nous produisons également de petits chariots, qui économisent beaucoup d'espace. Il est facile à utiliser. Le plus important est que cela diminue votre coût.

L'autre méthode de séchage consiste à utiliser une machine de séchage de plateaux à œufs, qui est en métal. Le séchoir à plateaux à œufs utilise le charbon, le combustible ou l'électricité comme source de chaleur. Les plateaux à œufs moulés seront séchés à l'air chaud.

Ligne de production de machines à plateaux à œufs d'un côté

La ligne de production de machine à plateaux à œufs à 1 face comprend un mélangeur de pâte, une machine de formation, une pompe à vide, un système de pressage, un séchoir, un convoyeur et un équipement d'emballage.

Si nécessaire, nous pouvons également vous fournir une solution de ligne de production complète.

Cas de succès de petites machines de fabrication de plateaux à œufs

Notre machine a été exportée dans de nombreux pays étrangers, tels que le Nigeria, le Maroc, le Kenya, le Cameroun, la Zambie, Indonésie, l'Arabie Saoudite, l'Inde, etc. La petite machine à alvéoles à œufs modèle 1 côté convient aux débutants qui souhaitent démarrer cette activité. Nous pouvons vous apprendre à l'utiliser et également concevoir un dessin raisonnable pour vous. De plus, le modèle de capacité moyenne et grande est également proposé.

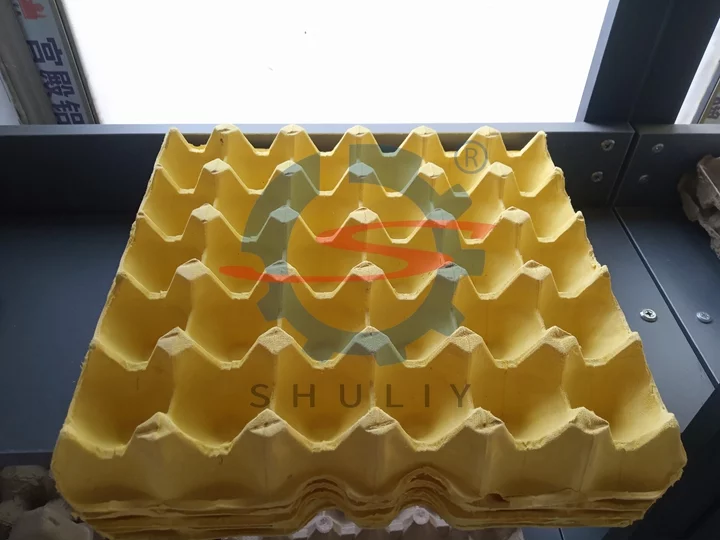

Affichage des produits finis de plateaux à œufs

Clients avec lesquels nous travaillons