Pulpe Weinablage Maschinen | Weinverpackungsablage Maschinen

| Marke | Shuliy Maschinen |

| Modell | SL-Serie |

| Kapazität | 1000-7000 Stück/h |

| Leistung | 38-120 kW |

| Spannung | 380V, 50HZ |

| Größe | Referenz-Technische Parameter Tabelle |

| Garantie | 12 Monate |

Sie können jetzt unsere Projektmanager nach technischen Details fragen.

Eine Maschine zur Herstellung von Papp-Weintray ist eine industrielle Ausrüstung, die entwickelt wurde, um geformte Papp-Weintrays herzustellen. Sie verwendet Prozesse wie Vakuumformen, Pressen und Trocknen, um die Pappe in verschiedene Tray-Designs zu formen.

Pulp-Weintrays sind umweltfreundliche Verpackungsmaterialien, die aus Abfallpapier, Kartons und ähnlichen Materialien unter Verwendung von Pulpmolding-Technologie hergestellt werden. Im Vergleich zu herkömmlicher Schaumverpackung sind Pulp-Weintrays umweltfreundlicher, biologisch abbaubar und bieten eine gute Polsterung, was sie besser für die modernen Anforderungen an umweltfreundliche Verpackungen macht.

Diese Weinverpackungsschalenmaschine spielt eine wichtige Rolle in modernen umweltfreundlichen Verpackungsproduktionslinien und eignet sich besonders für die Herstellung von Schalen für Glasflaschen wie Wein, Champagner und Spirituosen.

Shuliy bietet 7 Modelle von Zellstoffformmaschinen mit einer Kapazität von 1.000 bis 7.000 Stück/h und exportiert jährlich über 50 Einheiten.

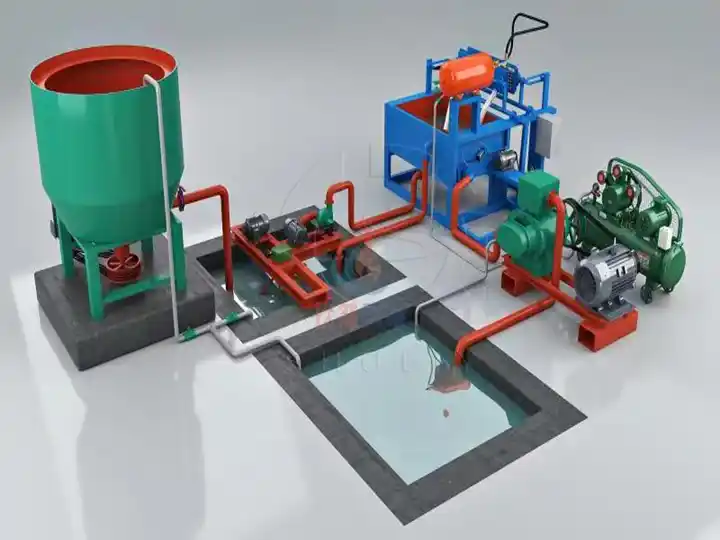

Hauptstruktur der Zellstoff-Weintray-Herstellungsmaschine

Die Zellstoff-Weinverpackungsschalenmaschine umfasst hauptsächlich das Pulpsystem, das Formsystem, das Trocknungssystem und das Verpackungssystem.

- Zellstoffsystem: Dies umfasst einen Pulper, einen Wassertank und einen Mischer. Er mischt Altpapier mit Wasser, um eine glatte Pulpe herzustellen. Er ist mit einem Steuergerät zur Konzentrationskontrolle der Pulpe verbunden.

- Formungssystem: Dies verwendet Vakuumformen, um das Papier unter negativem Druck zu formen. Die Form besteht aus oberen und unteren Teilen, die schnell gewechselt werden können, um sich an verschiedene Weinflaschenbehälter anzupassen. Der Formantrieb kann hydraulisch oder pneumatisch sein.

- Trockenanlage: Nach der Formgebung werden die feuchten Tabletts bei hohen Temperaturen getrocknet. Es gibt sechs Trocknungsmethoden zur Auswahl: natürliche Trocknung, Trockenschrank, ziegelgebaute Trockenkammer oder mehrschichtige Metalltrocknung. Dies stellt sicher, dass die Tabletts in der Größe stabil und auf der Oberfläche glatt sind.

- Verpackungsanlage: Trays können mit einem Stapler gezählt und gestapelt und dann für die Lieferung verpackt werden.

Technische Parameter der Shuliy Zellstoff-Weintray-Herstellungsmaschine

| Modell | Kapazität | Leistung | Spannung | Gewicht | Faserverbrauch | Wasserverbrauch | Größe (mm) |

| SL-1000-3X1 | 1000 Stück/h | 38 kW | 380V, 50HZ | 2500 kg | 80 kg/h | 160 kg/h | 2600*2200*1900 |

| SL-1500-4X1 | 1500 Stück/Stunde | 38 kW | 380V, 50HZ | 3000 kg | 120 kg/Stunde | 240 kg/Stunde | 2800*2200*1900 |

| SL-2500-3X4 | 2500Stück/h | 55kW | 380V, 50HZ | 4000kg | 200kg/h | 400kg/h | 2900*1800*1800 |

| SL-3000-4X4 | 3000Stück/h | 60kW | 380V, 50HZ | 4800kg | 240 kg/Stunde | 480kg/h | 3250*1800*1800 |

| SL-4000-4X8 | 4000Stück/h | 95kW | 380V, 50HZ | 7000kg | 320kg/h | 640kg/h | 3250*2300*2500 |

| SL-5000-5X8 | 5000 Stück/h | 95kW | 380V, 50HZ | 8000 kg | 400kg/h | 800 kg/h | 3700*2300*2500 |

| SL-7000-6X8 | 7000 Stück/Stunde | 120 kW | 380V, 50HZ | 10000 kg | 480kg/h | 960 kg/Stunde | 3200*2300*2500 |

Das oben Genannte ist unser Standardmodell zur Referenz. Wenn Sie spezifischere Anforderungen haben, können wir die Maschine auch nach Ihren Bedürfnissen anpassen.

Wie funktioniert die Maschine zur Formung von Zellstoff-Weinbehältern?

Ähnlich wie die Eierverpackungsschalenmaschine verwendet die Zellstoff-Weinverpackungsschalenformmaschine die Zellstoffformtechnologie. Sie folgt einem Zellstoffformprozess, bei dem der Zellstoff in eine Form eingespritzt wird. Dann wird die Schale durch Vakuumabsaugung geformt, hitzegeschützt und zu einer Schale mit spezieller Festigkeit und Design geformt.

Die Hauptarbeitsabläufe sind ebenfalls: Pulpen → Formen → Trocknen → Verpacken.

Vorteile der Shuliy Weinverpackungstray-Herstellungsmaschine

- Hohe Automatisierung: Vom Pulpen über Formen, Schneiden bis hin zum Verpacken ist der Prozess automatisiert, was Arbeitskosten spart.

- Umweltfreundliche Produktion: Keine Abwasser- oder Gasemissionen. Die Rohstoffe können erneut recycelt werden und entsprechen den lokalen Umweltrichtlinien.

- Maßgeschneiderte Formen: Geeignet für verschiedene Flaschengrößen und -typen (wie Bordeaux, Champagner, Spirituosenflaschen). Wir können auch Formen basierend auf den Flaschen anpassen, die Sie uns senden.

- Schöne Oberflächenbeschaffenheit: Die Tabletts sehen glatt und sauber aus, perfekt für hochwertige Wein-Geschenkboxen oder Ausstellungspräsentationen. Sie können die Farbe, das Logo-Prägung oder Muster anpassen, um Ihre Verpackung aufzuwerten.

- Verschiedene Tablettoptionen: Kann Tabletts für 1, 2, 6 oder 12 Flaschen herstellen.

- Stabile Leistung: Präzise Steuerung des Formdrucks, der Zeit und der Formanpassung, um eine konsistente Qualität sicherzustellen. Im Vergleich zu regulären Maschinen kann sie 2,5-mal länger betrieben werden.

- Hochpräzises Formsystem: Macht Tabletts stärker und stabiler, mit guter Gewichtsunterstützung und ohne verzogene Kanten. Das Tablett hat symmetrische Stützpunkte für bessere Leistung.

- Maßgeschneiderte Dienstleistungen verfügbar: Wir bieten designbasierte Muster, Flaschengrößenanpassung, Logo-Prägung, Farbgestaltung und mehr an, um Ihre Marke hervorzuheben. Komplettlösungen für Verpackungen können mit der Tray-Formmaschine bereitgestellt werden.

- Vollständige Produktionslinie und Lösung verfügbar: Als Direkthersteller können wir Aufbereitungsmaschinen, Luftkompressoren, Trockner und andere Geräte bereitstellen. Wir bieten auch eine vernünftige Planung der Flächenaufteilung an, um Ihre Arbeitskosten zu senken.

Welche Arten von Zellstoff-Weinbehältern gibt es?

| Kategorie | Typ |

| Nach Flaschenvolumen | 187ml, 375ml, 500ml, 700ml, 750ml, 1L, 1.5L, 3L / 5L |

| Nach Flaschenanzahl | Einzel-Flasche, Zwei-Flaschen, Vier-Flaschen, Sechs-Flaschen, Zwölf-Flaschen |

| Nach Struktur | Einteiliger Typ, Oben und unten separater Typ, Einsetzt-Typ |

| Nach Formgebungsprozess | Trockenpressen, Nasspressen |

| Nach Verwendung | Transport-Schutztyp, Geschenkbox-Darstellungstyp, Exporttyp |

Warum eine Maschine zur Herstellung von Weinverpackungsbehältern wählen?

Es hat breite Anwendungen:

- Weinhersteller: Verwendet für die Innenverpackung von Flaschenweinen.

- E-Commerce-Plattformen: Ideal für den sicheren Versand von einzelnen oder mehreren Weinflaschen.

- Geschenkverpackungsunternehmen: Verwendet für Tabletts in Geschenkweinboxen oder Premium-Weinsets.

- Exporthändler: Entspricht den Vorschriften für umweltfreundliche Verpackungen in der EU, den USA und anderen Ländern.

- Supermärkte und Einzelhandelsgeschäfte: Wird für Kombipackungen verwendet, um die Präsentation und den Verkauf zu erleichtern.

Vorteile im Vergleich zu anderen Verpackungsmaterialien:

| Artikel | Papierweintablett | Schaumstofftablett | Wellpappeinsatz |

| Umwelt | Biologisch abbaubar, umweltfreundlich | Nicht biologisch abbaubar | Recycelbar |

| Schutz | Stark | Sehr stark | Mittel |

| Kosten | Mittel | Höher | Niedrig |

| Anpassung | Hoch | Mittel | Mittel |

| Erscheinung | Gut (besser mit Nasspressung) | Arm | Mittel |

Fertige Produkte von der Zellstoff-Weintray-Herstellungsmaschine

Die Pulp-Weintrays, die wir häufig produzieren, sind unten abgebildet. Wir haben jedoch viele andere Formen zur Verfügung. Wenn Sie interessiert sind, können Sie uns jederzeit kontaktieren!

Versandanzeige der Maschine zur Herstellung von Pulpe-Weintrays

Hier sind einige unserer Versandfotos. Sie können sich unsere Verpackung ansehen.