鞋托盘制造机

| 品牌 | 树立机械 |

| 型号 | SL系列 |

| 容量 | 1000-7000个/小时 |

| 功率 | 38-120千瓦 |

| 电压 | 380V, 50HZ |

| 尺寸 | 参考技术参数表 |

| 保修 | 12个月 |

您现在可以向我们的项目经理询问技术细节

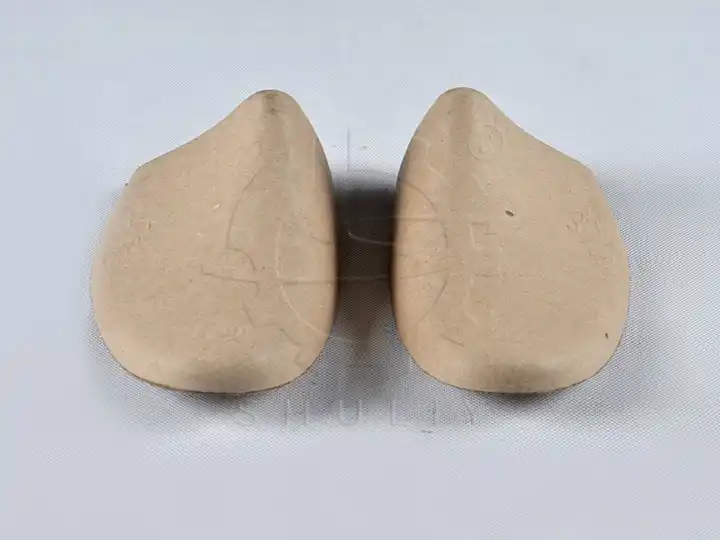

鞋托成型机是一种专门用于生产模塑纸浆鞋托的设备。它以废纸浆为原料,通过制浆、成型、脱模、干燥等工序,批量生产用于鞋子包装的纸浆包装,包括鞋插、鞋撑和鞋底托盘。

鞋托广泛用于运动鞋、皮鞋、休闲鞋和童鞋的包装。它们是塑料和泡沫包装的环保、可生物降降解的替代品。

我们全自动鞋托成型机的生产能力范围为每小时 1,000 至 7,000 件。我们还提供定制模具设计,以满足您特定的尺寸和形状要求。

鞋托制造机的工作原理

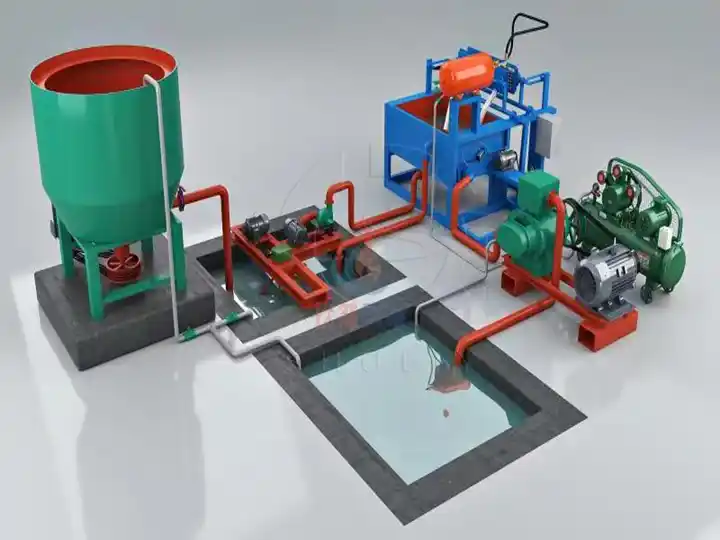

该机器使用真空成型技术:

打浆系统

废纸被处理成均匀的纸浆。

成型系统

- 模具浸入纸浆槽中。

- 真空泵将纸浆抽到模具表面。

- 模具上升以去除多余的水分。

脱模

压缩空气或机械力将湿托盘推出。

干燥

托盘使用干燥炉或干燥室进行干燥。

修整与成型

最终成型、边缘修整和包装。

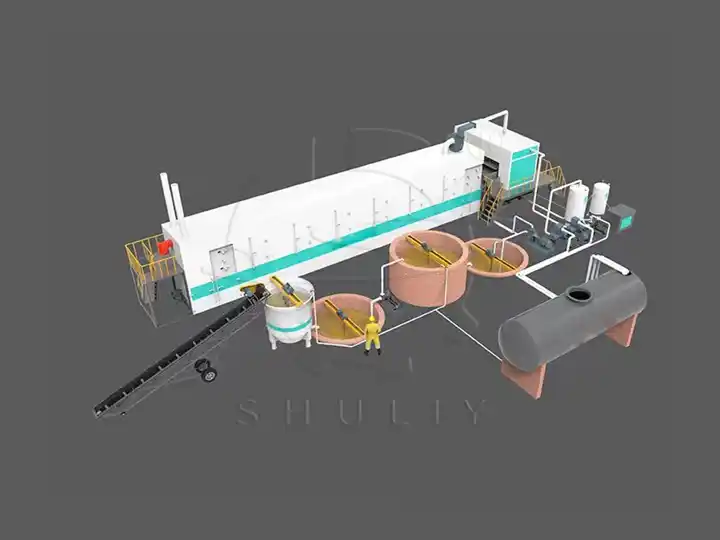

主要工作步骤

制浆 → 成型 → 干燥 → 包装。

机器组件

- 浆料罐 – 均匀储存和混合浆料

- 主成型机 - 核心成型单元与模具座。

- 真空泵 – 将浆料吸入模具中

- 空气压缩机系统 - 有助于产品的排出

- 模具系统 - 定制模具定义托盘形状

- 干燥设备 - 电热或热风干燥

- 控制面板 - PLC系统设置真空、时间和温度。

热销鞋托成型机出售

| 型号 | 容量 | 功率 | 电压 | 重量 | 浆料使用 | 水使用 | 尺寸(毫米) |

| SL-1000-3X1 | 1000个/小时 | 38千瓦 | 380V, 50HZ | 2500千克 | 80千克/小时 | 160千克/小时 | 2600*2200*1900 |

| SL-1500-4X1 | 1500个/小时 | 38千瓦 | 380V, 50HZ | 3000千克 | 120千克/小时 | 240千克/小时 | 2800*2200*1900 |

| SL-2500-3X4 | 2500个/小时 | 55千瓦 | 380V, 50HZ | 4000千克 | 200千克/小时 | 400千克/小时 | 2900*1800*1800 |

| SL-3000-4X4 | 3000件/小时 | 60千瓦 | 380V, 50HZ | 4800千克 | 240千克/小时 | 480千克/小时 | 3250*1800*1800 |

| SL-4000-4X8 | 4000件/小时 | 95千瓦 | 380V, 50HZ | 7000千克 | 320千克/小时 | 640千克/小时 | 3250*2300*2500 |

| SL-5000-5X8 | 5000件/小时 | 95千瓦 | 380V, 50HZ | 8000千克 | 400千克/小时 | 800千克/小时 | 3700*2300*2500 |

| SL-7000-6X8 | 7000件/小时 | 120千瓦 | 380V, 50HZ | 10000千克 | 480千克/小时 | 960千克/小时 | 3200*2300*2500 |

我们可以根据您的要求通过添加或删除功能来定制机器。如需更多信息,请随时与我们联系。

为什么选择舒立鞋托成型机?

环保和可生物降解

- 由回收纸(报纸、瓦楞纸、书籍)制成。

- 100% 可生物降解,符合全球“减少塑料”目标

- 适合出口到 欧盟,美国 以及其他环保意识强的市场

高度可定制

- 针对不同鞋码和类型定制的模具

- 可以生产单层或双层鞋托、鞋垫、内垫等

- 标志/可以在模具上雕刻纹理图案以进行品牌推广

节省成本和空间效率

- 低原材料成本

- 可堆叠、可压缩的结构节省运输空间

- 高耐用性减少运输过程中的产品损坏

灵活的输出选项

- 产能范围从 每小时1000到7000个

- 可提供从半自动单站到 全自动 多站线

- 适合鞋类制造商、电子商务或包装服务提供商

稳定的性能和简单的操作

- PLC触摸屏控制, 直观且高效

- 快速换模系统实现多产品切换

- 由不锈钢或涂层碳钢制成的耐用框架

多用途使用

- 通过更换模具,同一台机器还可以生产: 酒托/ 化妆品包装 / 电子插入 /小家电托盘

提升您的品牌形象

- 优雅且可持续的包装提升产品吸引力

- 定制压花托盘反映品牌形象

- 符合环保要求的出口,增强买家信心

常见鞋垫类型

- 鞋垫 - 用于保持鞋子的形状

- 底托 - 用于包装鞋子配对

- 盒内衬 - 用于鞋盒内部保护

- logo印章托盘 - 定制品牌

模具设计技巧

- 良好的通风布局以确保顺畅的纸浆吸取

- 光滑的边缘以减少修剪

- 表面处理(喷砂/抛光)以获得纹理

- 快速更换结构以提高模具更换效率

- 高精度和防腐处理延长使用寿命

何时使用鞋垫成型机

环保鞋包装的大规模生产

当您需要生产大量可生物降解的鞋托,用于运动鞋、皮鞋或儿童鞋时。

替代塑料或泡沫包装

如果您的品牌或客户正在朝着可持续包装解决方案发展,以满足环保法规。

鞋包装出口要求

当出口到有严格环保政策的地区(例如,欧洲、北美)时,需要可回收、无塑料的包装。

定制鞋支撑解决方案

当您需要定制模具托盘,例如鞋垫、底托或带有标志或图案的品牌包装时。

降低包装成本

当寻找泡沫或塑料的成本效益替代品,且原材料和运输成本较低时。

建立内部包装生产

对于希望控制质量并通过现场生产托盘来减少外包的鞋厂或包装公司。