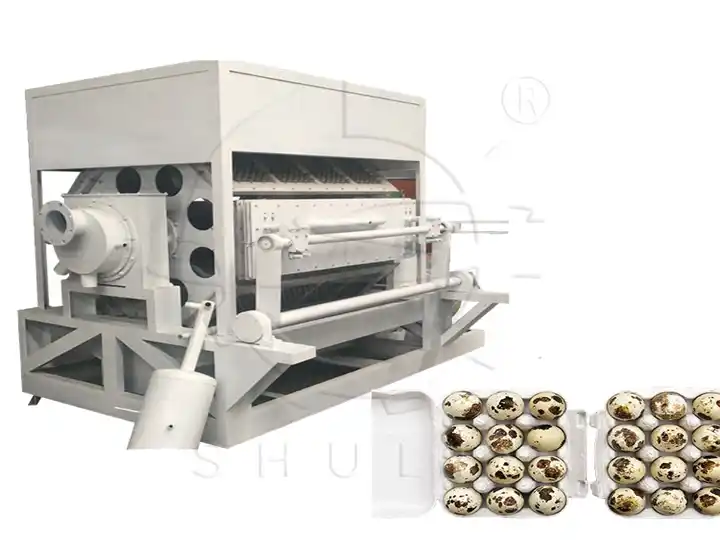

Mesin Pembuat Baki Telur Puyuh

| Model | SL-2500-3X4 |

| Kapasitas | 2500pcs/jam |

| Daya | 55kw |

| Tegangan | 380V,50HZ |

| Ukuran (mesin cetak) | 2900*1800*1800mm |

| Konsumsi kertas | 200kg/jam |

| Konsumsi air | 400kg/jam |

Anda sekarang dapat meminta detail teknis kepada manajer proyek kami

Mesin pembuat baki telur puyuh adalah peralatan pencetakan pulp yang dirancang khusus untuk memproduksi baki telur puyuh. Mesin ini bekerja dengan mencampurkan kertas bekas, air, dan bahan tambahan menjadi pulp, kemudian membentuk baki melalui pencetakan, pengeringan, dan pemanasan. Baki ini terbuat dari pulp kertas dan digunakan untuk mengemas serta melindungi telur puyuh.

Tray telur puyuh yang diproduksi sebagian besar terbuat dari pulp kertas daur ulang, yang dapat terurai secara hayati atau didaur ulang, memenuhi standar ramah lingkungan. Mereka cocok untuk ekspor dan permintaan pasar modern.

Perusahaan kami menawarkan berbagai kapasitas produksi dan spesifikasi berbeda dari mesin pembuat baki telur puyuh, yang cocok untuk produksi dan penjualan skala besar, serta kebutuhan ekspor telur puyuh. Kami telah mengekspor ke lebih dari 10 negara, termasuk Filipina, Vietnam, Jepang, Indonesia, Arab Saudi, dan Prancis.

Struktur Utama Mesin Pembuat Tray Telur Puyuh

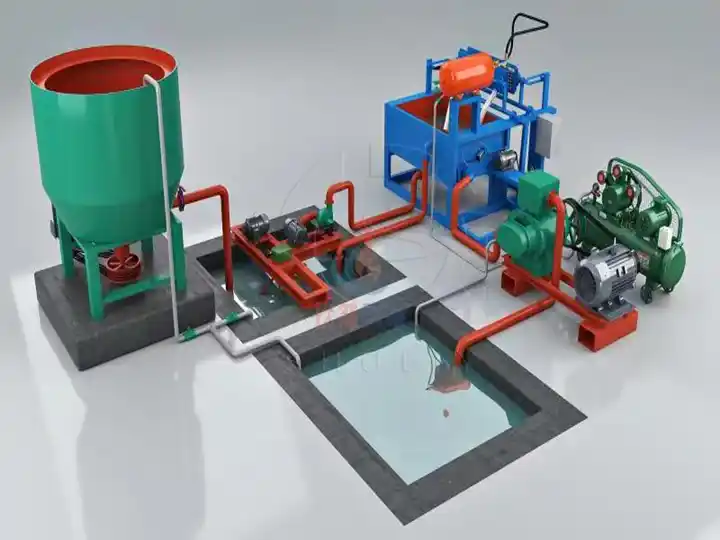

Mirip dengan mesin tray telur ayam, komponen utama dari mesin pembuat tray telur puyuh meliputi:

- sistem pulping: Mengandung penghancur pulp, tangki pencampur, dan pompa pulp, digunakan untuk pemrosesan bahan baku.

- Sistem pembentukan tray: Peralatan pembentukan inti dengan cetakan dan perangkat penggerak. Cetakan dapat diganti untuk memproduksi tray telur puyuh dengan ukuran yang berbeda.

- Sistem pengeringan tray: Biasanya menggunakan pengeringan alami, oven pengering, ruang pengering bata, atau pengering logam multi-lapis.

- Sistem pengemasan tray: Menggunakan mesin penumpuk dan pengemasan untuk menghitung dan menumpuk, memudahkan pengemasan dan transportasi produk jadi.

Model dan Parameter Mesin Pembuat Tray Telur Puyuh

| Model | Kapasitas | Daya | Tegangan | Berat | Konsumsi kertas | Konsumsi air | Ukuran (mesin cetak) |

| SL-1000-3X1 | 1000pcs/jam | 38kw | 380V,50HZ | 2500kg | 80kg/jam | 160kg/jam | 2600*2200*1900mm |

| SL-1500-4X1 | 1500pcs/jam | 38kw | 380V,50HZ | 3000kg | 120kg/jam | 240kg/jam | 2800*2200*1900mm |

| SL-2500-3X4 | 2500pcs/jam | 55kw | 380V,50HZ | 4000kg | 200kg/jam | 400kg/jam | 2900*1800*1800mm |

| SL-3000-4X4 | 3000pcs/jam | 60kw | 380V,50HZ | 4800kg | 240kg/jam | 480kg/jam | 3250*1800*1800mm |

| SL-4000-4X8 | 4000pcs/jam | 95kw | 380V,50HZ | 7000kg | 320kg/jam | 640kg/jam | 3250*2300*2500mm |

| SL-5000-5X8 | 5000pcs/jam | 95kw | 380V,50HZ | 8000kg | 400kg/jam | 800kg/jam | 3700*2300*2500mm |

| SL-7000-6X8 | 7000pcs/jam | 120kw | 380V,50HZ | 10000kg | 480kg/jam | 960kg/jam | 3200*2300*2500mm |

Di atas adalah model standar kami untuk referensi Anda. Jika Anda memiliki persyaratan khusus, kami dapat menyesuaikan mesin sesuai kebutuhan Anda.

Mengapa Memilih Mesin Tray Telur Puyuh Shuliy?

- Kustomisasi fleksibel: Ukuran cetakan, kapasitas, dan metode pemanasan (listrik, gas alam, diesel) dapat disesuaikan sesuai kebutuhan pelanggan dengan biaya rendah.

- Otomatisasi tinggi: Dari penggilingan, pembentukan, pengeringan, hingga pengemasan, seluruh proses dapat sepenuhnya otomatis untuk menghemat biaya tenaga kerja.

- Presisi cetakan yang tinggi: Piringan lebih kuat dan stabil, tanpa tepi yang melengkung, dan pas dengan telur puyuh. Piringan memiliki ketebalan sedang, menjadikannya ringan namun mendukung.

- Sistem kontrol penyedotan pulp pintar: Memastikan penyedotan pulp yang konsisten di setiap rongga cetakan.

- Sistem jalur pengeringan profesional: Menjamin pengeringan nampan yang merata dan cepat.

- Kustomisasi cetakan nampan telur puyuh profesional: Menjamin ukuran yang tepat dan pengaturan yang wajar.

Aplikasi Mesin Pembuat Tray Telur Puyuh

- Peternakan Puyuh

- Pusat penyortiran telur / pabrik pengolahan telur

- Pabrik kemasan baki kertas

- Pasar pertanian / pasar grosir

- Perusahaan e-commerce dan pengiriman makanan segar

- Supermarket dan outlet ritel

- Perusahaan perdagangan ekspor

Bagaimana Cara Kerja Mesin Pembentuk Tray Telur Puyuh?

Alur kerja dapat disederhanakan sebagai: Kertas bekas → Pulping → Pembentukan hisap pulp → Pelepasan cetakan → Pengeringan → Pembentukan → Pengemasan

- Penggilingan bahan baku: Kertas bekas dihancurkan dan dicampur dengan air untuk membentuk pulp yang seragam, mempersiapkan untuk pencetakan.

- Pembentukan hisap pulp: Cetakan dicelupkan ke dalam tangki pulp, dan penyedotan vakum menarik pulp ke permukaan cetakan. Ini adalah proses kunci dari mesin.

- Pengeluaran dan transfer: Setelah pembentukan, baki basah dikeluarkan dari cetakan dengan cara pneumatik atau mekanis.

- Pengeringan: Pengeringan alami atau peralatan pengeringan dapat digunakan.

- Menghitung, menumpuk, dan mengemas: Penghitungan otomatis, penumpukan, dan pengemasan untuk memudahkan transportasi dan penjualan.

Jika penampilan yang lebih halus dan kekuatan yang lebih kuat diperlukan, baki telur puyuh yang telah dikeringkan dapat menjalani proses pemanasan dan pembentukan ulang sekunder.

Pemeliharaan dan Tindakan Pencegahan untuk Mesin Tray Telur Puyuh

- Pemeliharaan harian: Setelah produksi harian, bersihkan cetakan, periksa sistem penyedotan pulp, dan lumasi rantai, panduan, silinder, dan batang penghubung di titik yang ditentukan.

- Pemeliharaan mingguan: Periksa keausan cetakan, periksa tingkat dan kualitas minyak pompa vakum, dan ganti minyak secara teratur. Juga, periksa sensor dan panel kontrol untuk operasi normal dan pantau untuk alarm yang tidak normal.

- Pemeliharaan bulanan: Periksa motor, sabuk, dan bantalan; kencangkan sekrup dan konektor mesin.

- Tindakan pencegahan: Jangan membongkar peralatan tanpa pengetahuan profesional. Jika terjadi kerusakan, silakan hubungi dukungan teknis purna jual. Gunakan hanya suku cadang asli untuk penggantian.

Jenis-jenis Tray Telur Puyuh

| Kapasitas | Aplikasi | Material |

| Nampan 10 telur | Nampan Display Ritel | Dari Pulp Molded |

| Nampan 20/30 telur | Nampan Transportasi | Plastik |

| 60 telur dan lebih | Tray Ekspor Sekali Pakai | Busa |

Nampan telur puyuh yang dibentuk dari pulp adalah yang paling umum. Mereka ringan, menyerap kelembapan, dan bernapas, dengan opsi pencetakan yang dapat disesuaikan. Nampan ini banyak digunakan di peternakan, supermarket, e-commerce, dan bidang lainnya.

Pameran Produk Akhir Tray Telur Puyuh

Berikut adalah gambar referensi dari produk akhir nampan telur puyuh standar kami.

Kasus Ekspor Mesin Pembuat Tray Telur Puyuh

Bekerja sama dengan kami

Jika tertarik, silakan hubungi kami untuk detail melalui WhatsApp secara langsung: https://wa.me/+8619139761487