Mesin Pembuat Baki Buah

| Merek | Mesin Shuliy |

| Model | Seri SL |

| Kapasitas | 1000-7000pcs/jam |

| Daya | 38-120kw |

| Tegangan | 380V,50HZ |

| Ukuran | Tabel Parameter Teknis Referensi |

| Garansi | 12 bulan |

Anda sekarang dapat meminta detail teknis kepada manajer proyek kami

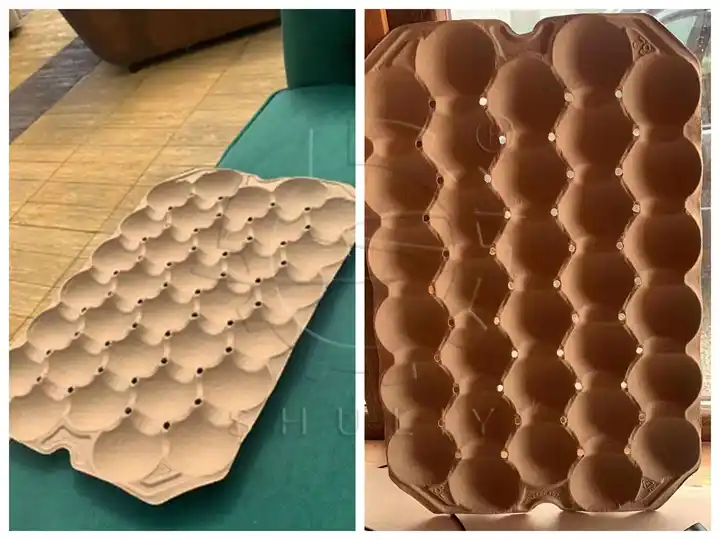

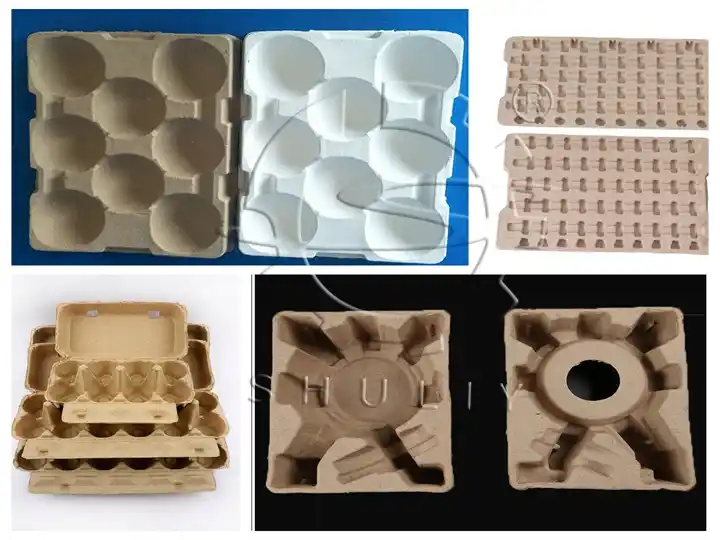

Mesin pembuat nampan pulp tidak hanya digunakan untuk membuat nampan telur, tetapi juga dapat digunakan untuk memproduksi nampan buah. Mesin ini juga dikenal sebagai mesin pembuat nampan buah atau mesin pembuat nampan kemasan buah dan sayuran. Mirip dengan mesin pembuat nampan telur, mesin ini menggunakan kertas bekas dan karton lama sebagai bahan baku, yang diproses melalui pulping, penyaringan, dan pencampuran air untuk membuat bubur kental untuk membuat nampan.

Mesin pembuat nampan buah ini banyak digunakan untuk pengemasan ramah lingkungan untuk buah-buahan seperti apel, pir, jeruk, dan kiwi. Mesin ini merupakan alternatif ramah lingkungan untuk nampan plastik, karena dapat terurai, dapat didaur ulang, dan ramah lingkungan.

Nampan buah memiliki berbagai macam kegunaan. Nampan ini terutama digunakan di pasar grosir buah, pusat distribusi supermarket, perusahaan ekspor buah, pabrik pengemasan ramah lingkungan, dan perkebunan buah. Karena permintaan yang tinggi, pasar memiliki potensi besar, dan pengembalian investasi cukup besar.

Shuliy telah berfokus pada pengembangan dan produksi mesin pembuat nampan buah selama lebih dari 10 tahun. Dengan pengalaman ekspor yang kaya, Shuliy adalah salah satu produsen dan eksportir terkemuka di Tiongkok. Setiap tahun, kami mengekspor banyak mesin pembuat nampan buah ke negara-negara seperti Brasil, Kuba, Kolombia, Rusia, Ghana, Kamerun, Nigeria, Prancis, Zambia, Selandia Baru, Peru, Uzbekistan, Sudan, dan banyak lagi.

Bagaimana cara kerja mesin pembuat baki buah?

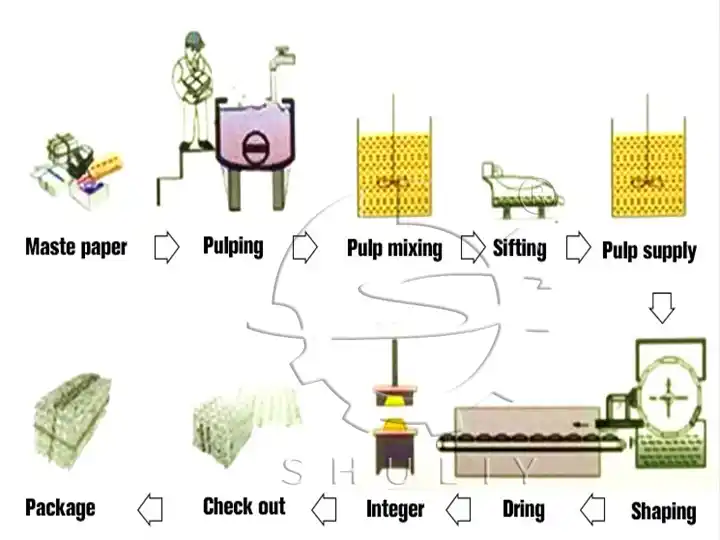

Sama seperti mesin tray telur, mesin pembuat tray buah menggunakan teknologi pembentukan pulp. Prosesnya mengikuti proses pembentukan pulp di mana pulp disuntikkan ke dalam cetakan. Kemudian, tray dibentuk dengan hisapan vakum, dikeringkan dengan panas, dan dibentuk menjadi tray dengan kekuatan dan desain tertentu.

Langkah kerja utama adalah: pulping → pembentukan → pengeringan → pengemasan.

Apa saja bagian utama dari mesin pembuat nampan buah?

Mesin pembuat nampan buah terutama mencakup sistem berikut: sistem pulping, sistem pembentukan, sistem pengeringan, sistem pengepresan panas, dan sistem kontrol.

Peralatan utamanya meliputi:

mesin pulping, kompresor udara, mesin pembentuk, mesin pengering, dan mesin pengemas. Kami dapat menyediakan jalur produksi nampan buah yang lengkap.

Apa saja keuntungan dari mesin pembuat nampan buah Shuliy?

- Ramah lingkungan dan hemat energi: Menggunakan kertas bekas sebagai bahan baku, yang dapat didaur ulang. Ini sangat mengurangi biaya dan membantu melindungi lingkungan.

- Otomatisasi tinggi: Mendukung pembentukan, pengeringan, dan pengemasan otomatis. Mudah dioperasikan dengan biaya tenaga kerja yang rendah.

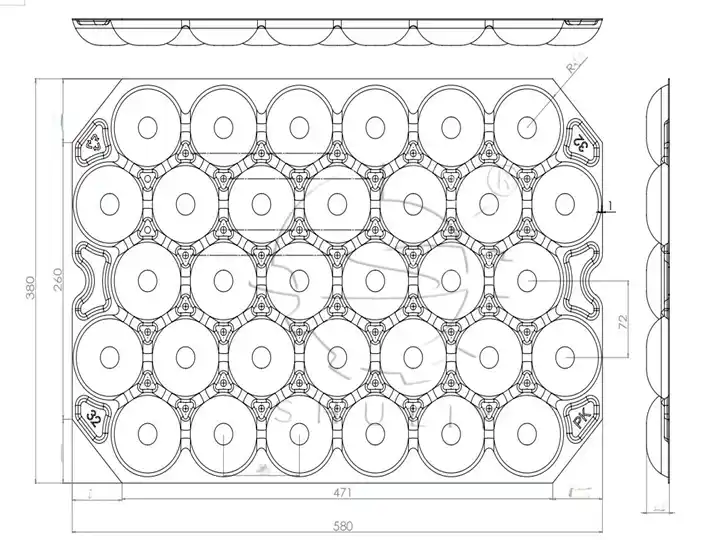

- Adaptabilitas yang kuat: Cetakan dapat diganti untuk memproduksi nampan dengan ukuran yang berbeda, cocok untuk berbagai jenis kemasan buah.

- Kustomisasi fleksibel: Kami mendukung ukuran dan bentuk cetakan kustom. Tim desain 3D profesional kami dapat menyediakan gambar dan simulasi produksi untuk mengurangi risiko sebelum pembelian. Kami juga dapat membantu menyiapkan jalur produksi penuh.

- Berbagai pilihan kapasitas: Kami menawarkan mesin pembuat nampan buah dengan kapasitas output yang berbeda, dari 1000 hingga 7000 buah per jam.

Apa saja model populer dari mesin pembentuk nampan buah Shuliy?

| Model | Kapasitas | Daya | Tegangan | Berat | Konsumsi kertas | Konsumsi air | Ukuran (mesin cetak) |

| SL-1000-3X1 | 1000pcs/jam | 38kw | 380V,50HZ | 2500kg | 80kg/jam | 160kg/jam | 2600*2200*1900mm |

| SL-1500-4X1 | 1500pcs/jam | 38kw | 380V,50HZ | 3000kg | 120kg/jam | 240kg/jam | 2800*2200*1900mm |

| SL-2500-3X4 | 2500pcs/jam | 55kw | 380V,50HZ | 4000kg | 200kg/jam | 400kg/jam | 2900*1800*1800mm |

| SL-3000-4X4 | 3000pcs/jam | 60kw | 380V,50HZ | 4800kg | 240kg/jam | 480kg/jam | 3250*1800*1800mm |

| SL-4000-4X8 | 4000pcs/jam | 95kw | 380V,50HZ | 7000kg | 320kg/jam | 640kg/jam | 3250*2300*2500mm |

| SL-5000-5X8 | 5000pcs/jam | 95kw | 380V,50HZ | 8000kg | 400kg/jam | 800kg/jam | 3700*2300*2500mm |

| SL-7000-6X8 | 7000pcs/jam | 120kw | 380V,50HZ | 10000kg | 480kg/jam | 960kg/jam | 3200*2300*2500mm |

Jenis baki buah apa yang bisa dibuat?

- Nampan Apel: Jenis umum memiliki desain 10 lubang, 15 lubang, atau 20 lubang. Setiap buah memiliki slotnya sendiri untuk mencegah kerusakan selama transportasi.

- Nampan Jeruk / Citrus: Biasanya dengan 12 atau 15 lubang. Slotnya lebih dalam dan bulat, sempurna untuk menampung buah bulat dan mencegahnya berguling.

- Nampan Kiwi: Sering dilengkapi dengan 8 atau 16 lubang, terkadang dirancang dalam dua lapisan. Jenis ini melindungi buah-buahan lunak dari tekanan dan kerusakan.

- Nampan Pir: Terbuat dari bahan pulp lembut. Ukuran lubangnya lebih besar, cocok untuk buah besar seperti pir salju.

- Tatakan anggur: Nampan datar dan dangkal yang digunakan untuk menampung kumpulan anggur yang sudah dikemas dalam kantong busa.

- Tatakan stroberi: Biasanya terbuat dari plastik transparan atau nampan pulp dangkal yang dipadukan dengan kertas penyerap, disusun dalam satu lapisan untuk melindungi setiap berry.

Ukuran baki buah yang umum

| Jenis Buah | Jumlah Lubang | Diameter Lubang (mm) | Ukuran Nampan (mm) |

| Apel | 20 lubang | 80-100 | 400*300 |

| Jeruk | 12-15 lubang | 70-90 | 400*300 |

| Kiwi | 16 lubang | 60-70 | 350*250 |

| Pir | 10-15 lubang | 85-100 | 400*300 |

Ukuran yang terdaftar di atas adalah yang paling umum di pasar. Jika Anda memiliki kebutuhan kustomisasi khusus, silakan hubungi kami. Kami akan menghubungi Anda dalam waktu 24 jam!