Garis Produksi Nampan Anggur dari Pulp

| Merek | Mesin Shuliy |

| Model | Seri SL |

| Kapasitas | 1000-7000pcs/jam |

| Daya | 38-120kw |

| Tegangan | 380V,50HZ |

| Ukuran | Tabel Parameter Teknis Referensi |

| Garansi | 12 bulan |

Anda sekarang dapat meminta detail teknis kepada manajer proyek kami

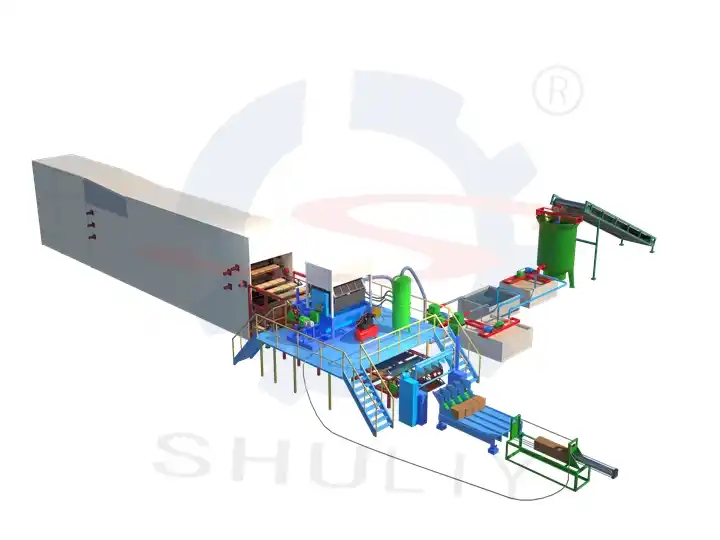

The pulp wine tray production line centers on the wine tray forming machine and uses molding technology to make various bottled wine trays.

Shuliy offers production lines with a capacity of 1,000–7,000 pcs/h, suitable for wine tray manufacturers of all sizes.

The pulp wine tray production line mainly includes a pulper, mixing tank, tray forming machine, dryer, and packing equipment. It can efficiently produce all types of wine trays, including for baijiu, red wine, grape wine, beer, whiskey, and more, protecting glass bottles during transport.

Shuliy can also custom-make tray molds for your bottles. From production planning to actual manufacturing, we provide one-stop service.

What is a pulp wine tray?

A pulp wine tray, also called a pulp bottle tray or wine bottle holder, is an eco-friendly packaging product made from waste paper pulp or plant fibers using molding technology. It is commonly used to protect glass bottles of red wine, baijiu, spirits, beer, and other beverages. It can replace traditional foam or plastic inserts, providing shock resistance and compression protection, while being green, recyclable, and biodegradable.

Process of a wine tray production line

A wine tray production line usually includes the following main steps:

sistem pulping

- Function: Crush waste paper, cardboard, or straw fibers, add water, and mix to make pulp with a concentration of about 3%–5%.

- Mesin: Penggiling hidrolik, tangki pencampur, layar penggiling

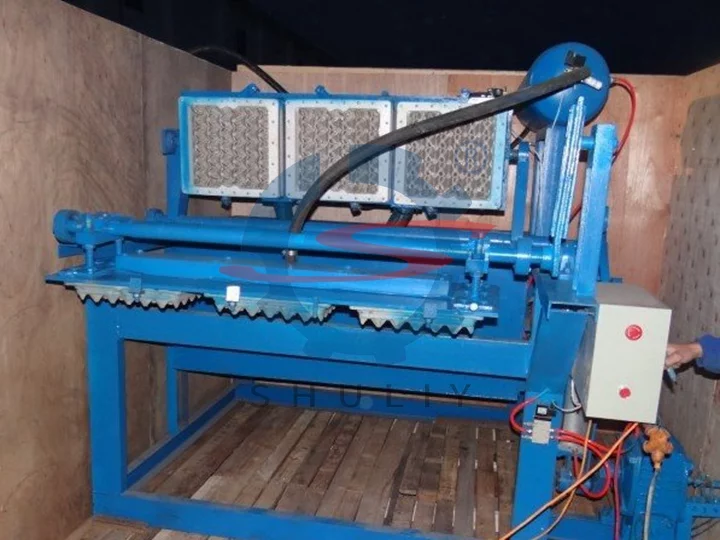

Sistem Pembentukan

- Function: Use a vacuum to remove excess water and shape the pulp into wine trays.

- Machines: Fully automatic pulp wine tray forming machine

sistem pengeringan

- Function: Transport trays to a mesh belt dryer or drying room. Dry with hot air at 180–220°C to remove moisture. Fuel options include coal, wood, natural gas, or diesel.

- Mesin: Pengering sabuk jala logam atau ruang pengeringan batu bata

Hot Shaping

- Function: Heat molds to 200°C and applies downward pressure (20 tons) to make the tray surface smooth. Usually required for special-shaped products.

- Machines: Hot press machine

Packaging & Stacking

- Function: Stack and pack the wine trays.

- Mesin: Mesin pengemas

Technical specifications

| Model | Kapasitas | Daya | Tegangan | Berat | Penggunaan Pulp | Penggunaan Air | Ukuran(mm) |

| SL-1000-3X1 | 1000pcs/jam | 38kw | 380V,50HZ | 2500kg | 80kg/jam | 160kg/jam | 2600*2200*1900 |

| SL-1500-4X1 | 1500pcs/jam | 38kw | 380V,50HZ | 3000kg | 120kg/jam | 240kg/jam | 2800*2200*1900 |

| SL-2500-3X4 | 2500pcs/jam | 55kw | 380V,50HZ | 4000kg | 200kg/jam | 400kg/jam | 2900*1800*1800 |

| SL-3000-4X4 | 3000pcs/jam | 60kw | 380V,50HZ | 4800kg | 240kg/jam | 480kg/jam | 3250*1800*1800 |

| SL-4000-4X8 | 4000pcs/jam | 95kw | 380V,50HZ | 7000kg | 320kg/jam | 640kg/jam | 3250*2300*2500 |

| SL-5000-5X8 | 5000pcs/jam | 95kw | 380V,50HZ | 8000kg | 400kg/jam | 800kg/jam | 3700*2300*2500 |

| SL-7000-6X8 | 7000pcs/jam | 120kw | 380V,50HZ | 10000kg | 480kg/jam | 960kg/jam | 3200*2300*2500 |

Advantages of a wine tray production line

- Eco-friendly & Biodegradable: Made from waste paper, recyclable, and biodegradable.

- Strong Cushioning: Shockproof and pressure-resistant, protecting glass bottles during transport.

- High Output: Production lines with 1,000–7,000 pcs/h to match different production scales.

- Customizable: Molds can be tailored for different wine types, producing red wine trays, beer trays, spirits trays, etc.

- High Automation: PLC precision control enables fully automatic operation from pulping to drying; it can be equipped with a 6-layer metal mesh dryer.

Market outlook for wine trays

- Driven by Eco Trends: With global plastic bans, traditional foam (EPS) is being phased out. Governments and companies prefer more eco-friendly packaging.

- Growing Alcohol Consumption: According to the International Organisation of Vine and Wine (OIV), about 24 billion liters of wine are consumed globally each year, and the beer market is even larger. Consumption of red wine, spirits, and craft beer continues to rise.

- Global Trade Requirements: Compared with foam, pulp wine trays save space in containers and reduce logistics costs.

- Versatile Applications: Wine trays can be used for single bottles or combinations of 2, 4, 6, or 12 bottles.

- Future Outlook: Strict environmental regulations in Europe and North America create strong demand for pulp trays to replace plastic. In China, Japan, and South Korea, growing alcohol consumption drives eco-friendly packaging as a standard for imported wine. Developing countries are also expanding the use of wine trays.

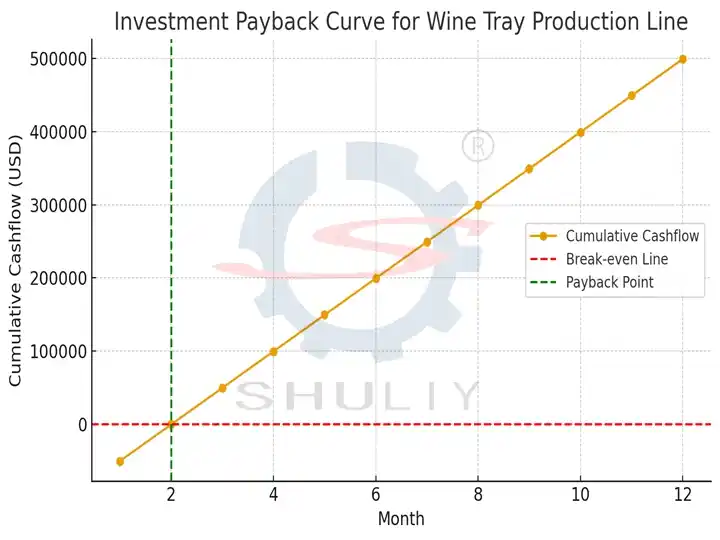

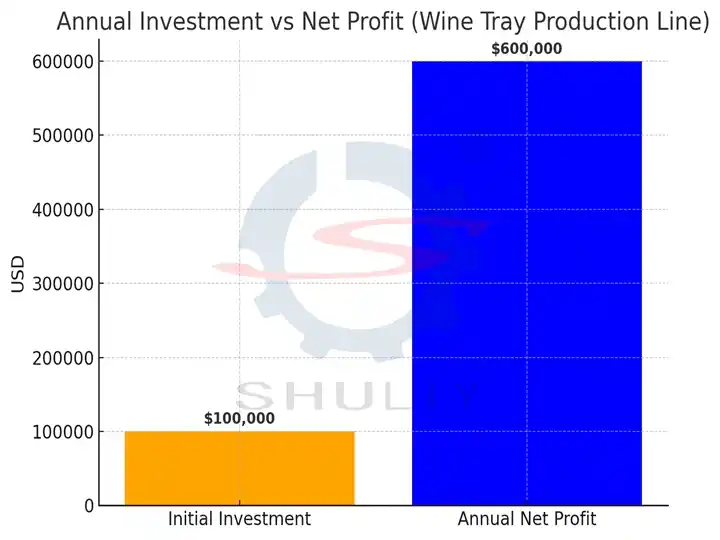

Investment Return Analysis of a Wine Tray Production Line

Taking an investment of $100,000 as an example, the following prices are for reference only. Actual costs may vary depending on the machines configured to meet specific production needs.

Investment costs

- Equipment purchase & installation: $80,000

- Factory & auxiliary facilities: $15,000

- Working capital (raw materials, labor, turnover): $5,000

- Total Investment: $100,000

Production capacity assumption

- Machine type: Small to medium fully automatic wine tray line

- Output: 2,000 pcs/h

- Operating time: 16 hours/day, 26 days/month

- Monthly output: 832,000 pcs

- Annual output: ≈ 10 million pcs

Cost per tray

- Raw material (waste pulp): $0.02

- Energy (electricity + water + fuel): $0.01

- Labor & management: $0.005

- Equipment depreciation & maintenance: $0.005

- Total cost: $0.04 per tray

Revenue estimate

- Selling price: $0.10 per tray (average)

- Profit: $0.06 per tray

- Monthly net profit: 832,000 × $0.06 ≈ $49,920

- Annual net profit: ≈ $600,000

Payback period

- Total investment: $100,000

- Monthly net profit: $49,920

- Payback period: about 2–3 months

Summary

With an investment of $100,000, a wine tray production line offers high returns and a short payback period. With stable orders, annual profit can exceed 6 times the investment, making it a typical high-value, eco-friendly packaging project.

Simulated investment curve of a wine tray production line

The image below is for reference only. For more detailed information, please contact us.

Annual revenue comparison chart

This chart compares a $100,000 investment with an annual net profit of $600,000, showing a very high return on investment.

Bermitra dengan Shuliy

- Shuliy provides complete wine tray production equipment that is affordable, durable, and made with high-quality steel.

- All equipment in Shuliy’s wine tray production lines meets ISO9001 and CE certification standards.

- 12-month warranty ensures long-term, reliable operation.

- Mold materials can be customized to provide the most cost-effective equipment combination.

- Shuliy exports 100 forming machines annually, ensuring smooth installation and operation worldwide. No matter where you are, we offer professional on-site installation service.