Mesin Pembuat Tray Anggur Pulp | Mesin Pembuat Tray Kemasan Anggur

| Merek | Mesin Shuliy |

| Model | Seri SL |

| Kapasitas | 1000-7000pcs/jam |

| Daya | 38-120kw |

| Tegangan | 380V,50HZ |

| Ukuran | Tabel Parameter Teknis Referensi |

| Garansi | 12 bulan |

Anda sekarang dapat meminta detail teknis kepada manajer proyek kami

Mesin pembuat nampan anggur pulp adalah peralatan industri yang dirancang untuk memproduksi nampan anggur dari pulp yang dicetak. Mesin ini menggunakan proses seperti pembentukan vakum, penekanan, dan pengeringan untuk membentuk pulp menjadi berbagai desain nampan.

Nampan anggur pulp adalah bahan kemasan ramah lingkungan yang terbuat dari kertas limbah, karton, dan bahan serupa menggunakan teknologi pencetakan pulp. Dibandingkan dengan kemasan busa tradisional, nampan anggur pulp lebih ramah lingkungan, dapat terurai secara hayati, dan menawarkan perlindungan yang baik, menjadikannya pilihan yang lebih baik untuk kebutuhan kemasan hijau modern.

Mesin Pembuat Nampan Kemasan Anggur ini memainkan peran penting dalam jalur produksi kemasan hijau modern, dan sangat cocok untuk membuat nampan botol kaca seperti anggur, sampanye, dan minuman keras.ª

Shuliy menawarkan 7 model mesin cetak pulp dengan kapasitas 1.000 hingga 7.000 pcs/jam, mengekspor lebih dari 50 unit per tahun.

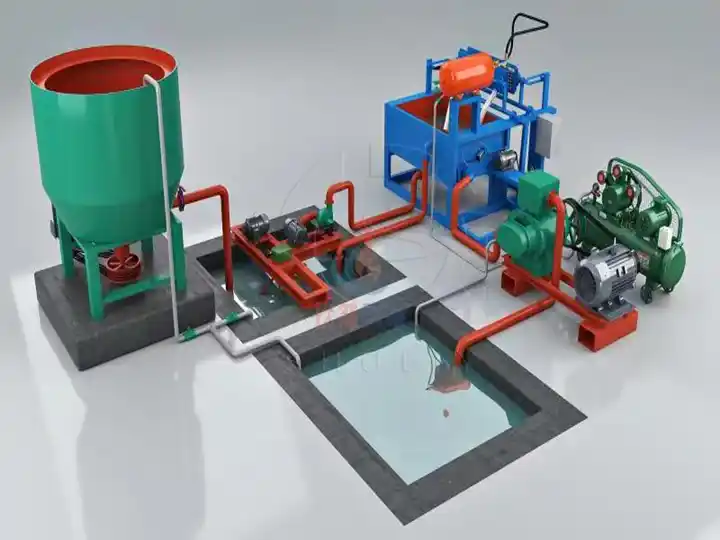

Struktur utama mesin pembuat nampan anggur pulp

Mesin pembuat nampan anggur pulp terutama meliputi sistem pulping, sistem pembentukan, sistem pengeringan, dan sistem pengemasan.

- Sistem Pulping: Ini termasuk mesin penggiling, tangki air, dan pengaduk. Ini mencampur kertas bekas dengan air untuk membuat pulp yang halus. Ini terhubung ke perangkat kontrol konsentrasi pulp.

- Sistem Pembentukan: Ini menggunakan cetakan hisap untuk membentuk pulp di bawah tekanan negatif. Cetakan terdiri dari bagian atas dan bawah, yang dapat dengan cepat diubah untuk menyesuaikan dengan baki botol anggur yang berbeda. Penggerak pembentukan dapat berupa hidrolik atau pneumatik.

- Sistem Pengeringan: Setelah dibentuk, nampan basah dikeringkan pada suhu tinggi. Ada enam metode pengeringan yang bisa dipilih: pengeringan alami, oven pengering, ruang pengering yang dibangun dari bata, atau pengeringan logam bertingkat. Ini memastikan nampan stabil dalam ukuran dan halus di permukaan.

- Sistem Pengemasan: Nampan dapat dihitung dan ditumpuk menggunakan stacker, kemudian dikemas untuk pengiriman.

Parameter teknis mesin pembuat nampan anggur pulp Shuliy

| Model | Kapasitas | Daya | Tegangan | Berat | Penggunaan Pulp | Penggunaan Air | Ukuran(mm) |

| SL-1000-3X1 | 1000pcs/jam | 38kw | 380V,50HZ | 2500kg | 80kg/jam | 160kg/jam | 2600*2200*1900 |

| SL-1500-4X1 | 1500pcs/jam | 38kw | 380V,50HZ | 3000kg | 120kg/jam | 240kg/jam | 2800*2200*1900 |

| SL-2500-3X4 | 2500pcs/jam | 55kw | 380V,50HZ | 4000kg | 200kg/jam | 400kg/jam | 2900*1800*1800 |

| SL-3000-4X4 | 3000pcs/jam | 60kw | 380V,50HZ | 4800kg | 240kg/jam | 480kg/jam | 3250*1800*1800 |

| SL-4000-4X8 | 4000pcs/jam | 95kw | 380V,50HZ | 7000kg | 320kg/jam | 640kg/jam | 3250*2300*2500 |

| SL-5000-5X8 | 5000pcs/jam | 95kw | 380V,50HZ | 8000kg | 400kg/jam | 800kg/jam | 3700*2300*2500 |

| SL-7000-6X8 | 7000pcs/jam | 120kw | 380V,50HZ | 10000kg | 480kg/jam | 960kg/jam | 3200*2300*2500 |

Di atas adalah model standar kami untuk referensi. Jika Anda memiliki kebutuhan yang lebih spesifik, kami juga dapat menyesuaikan mesin sesuai kebutuhan Anda.

Bagaimana cara kerja mesin pembentuk baki anggur pulp?

Mirip dengan mesin pembuat nampan telur, mesin pembentuk nampan anggur pulp mengadopsi teknologi pembentukan pulp. Ini mengikuti proses pembentukan pulp di mana pulp disuntikkan ke dalam cetakan. Kemudian, nampan dibentuk dengan hisapan vakum, dikeringkan dengan panas, dan dibentuk menjadi nampan dengan kekuatan dan desain khusus.

Langkah kerja utama juga adalah: pengolahan pulp → pembentukan → pengeringan → pengemasan.

Keuntungan dari mesin pembuat nampan kemasan anggur Shuliy

- Otomatisasi tinggi: Dari pengolahan pulp hingga pembentukan, pemangkasan, dan pengemasan, prosesnya otomatis, menghemat biaya tenaga kerja.

- Produksi ramah lingkunganTidak ada limbah cair atau emisi gas. Bahan baku dapat didaur ulang lagi, memenuhi kebijakan lingkungan setempat.

- Mold kustom: Cocok untuk berbagai ukuran dan jenis botol (seperti Bordeaux, Champagne, botol minuman keras). Kami juga dapat menyesuaikan cetakan berdasarkan botol yang Anda kirimkan kepada kami.

- Penyelesaian permukaan yang baik: Piringnya terlihat halus dan bersih, sempurna untuk kotak hadiah anggur premium atau tampilan showroom. Anda dapat menyesuaikan warna, emboss logo, atau pola untuk meningkatkan kemasan Anda.

- Banyak pilihan nampan: Dapat memproduksi nampan untuk 1, 2, 6, atau 12 botol.

- Kinerja yang stabil: Mengontrol tekanan pembentukan, waktu, dan kesesuaian cetakan dengan tepat untuk memastikan kualitas yang konsisten. Dibandingkan dengan mesin biasa, dapat beroperasi 2,5 kali lebih lama.

- Sistem cetakan presisi tinggiMembuat nampan lebih kuat dan lebih stabil, dengan dukungan berat yang baik dan tanpa tepi yang melengkung. Nampan memiliki titik dukungan simetris untuk kinerja yang lebih baik.

- Layanan kustom tersedia: Kami menawarkan desain berbasis sampel, pencocokan ukuran botol, embossing logo, kustomisasi warna, dan banyak lagi untuk membantu merek Anda menonjol. Solusi kemasan satu atap dapat disediakan dengan mesin pembentuk baki.

- Lini Produksi Penuh dan Solusi Tersedia: Sebagai produsen langsung, kami dapat menyediakan mesin pengolahan pulp, kompresor udara, pengering, dan peralatan lainnya. Kami juga menawarkan perencanaan tata letak lahan yang wajar untuk membantu mengurangi biaya tenaga kerja Anda.

Apa saja jenis-jenis baki anggur pulp?

| Kategori | Tipe |

| Berdasarkan Volume Botol | 187ml, 375ml, 500ml, 700ml, 750ml, 1L, 1.5L, 3L / 5L |

| Berdasarkan Jumlah Botol | Satu botol, Dua botol, Empat botol, Enam botol, Dua belas botol |

| Berdasarkan Struktur | Tipe satu bagian, Tipe terpisah atas dan bawah, Tipe sisipan |

| Berdasarkan Proses Pencetakan | Pencetakan tekan kering, Pencetakan tekan basah |

| Berdasarkan Penggunaan | Tipe perlindungan transportasi, Tipe tampilan kotak hadiah, Tipe ekspor |

Mengapa memilih mesin pembuat baki kemasan anggur?

Ini memiliki aplikasi yang luas:

- Produsen anggur: Digunakan untuk kemasan dalam produk anggur botolan.

- Platform e-commerce: Ideal untuk pengiriman aman satu atau beberapa botol anggur.

- Perusahaan kemasan hadiahDigunakan untuk nampan di dalam kotak hadiah anggur atau set anggur premium.

- Pedagang ekspor: Mematuhi peraturan kemasan ramah lingkungan di UE, AS, dan negara lainnya.

- Supermarket dan toko ritel: Digunakan untuk paket combo, membuat tampilan dan penjualan lebih nyaman.

Keuntungan dibandingkan dengan bahan kemasan lainnya:

| Barang | Piring Anggur Pulp | Piring Busa Plastik | Sisipan Kertas Bergelombang |

| Lingkungan | Biodegradable, ramah lingkungan | Tidak terurai secara hayati | Dapat didaur ulang |

| Perlindungan | Kuat | Sangat kuat | Sedang |

| Biaya | Sedang | Lebih Tinggi | Lebih Rendah |

| Kustomisasi | Tinggi | Sedang | Sedang |

| Penampilan | Baik (lebih baik dengan pengepresan basah) | Buruk | Sedang |

Produk jadi dari mesin nampan anggur pulp

Talenan anggur pulp yang sering kami produksi ditunjukkan di bawah ini. Namun, kami memiliki banyak pilihan cetakan lainnya yang tersedia. Jika Anda tertarik, jangan ragu untuk menghubungi kami kapan saja!

Tampilan pengiriman mesin pembuat baki anggur pulp

Berikut adalah beberapa foto pengiriman kami. Anda dapat melihat kemasan kami.