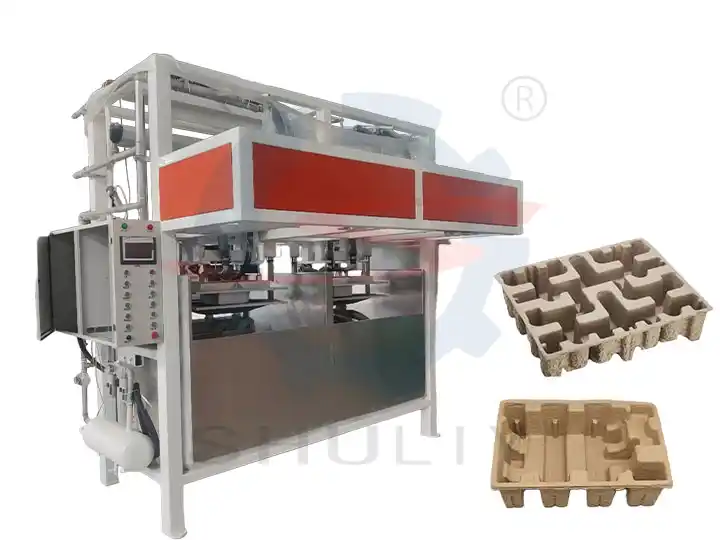

Machine de fabrication de plateaux d'emballage industriel

| Modèle | SL-R2000 |

| Capacité | 1000-2000pcs/h |

| Tension | 380V,50HZ |

| Utilisation de pulpe | 200kg/h |

| Utilisation d'eau | 400kg/h |

| Taille (mm) | 2900*1800*1800 |

| Garantie | 12 Mois |

Vous pouvez maintenant demander des détails techniques à nos chefs de projet.

La machine de fabrication de plateaux d'emballage industriel est un équipement qui utilise la technologie de moulage de pâte pour transformer la pâte recyclable en plateaux pour l'emballage industriel.ª

La machine de fabrication de plateaux d'emballage industriel Shuliy est largement utilisée dans des domaines tels que les composants électroniques, les pièces de machines, les pièces automobiles, les instruments optiques et l'emballage médical, pour protéger l'intégrité des pièces internes.

Shuliy fournit principalement un modèle de machine de moulage de plateaux d'emballage industriel, avec une capacité de production de 1 000 à 2 000 pièces/h.

Avec la prise de conscience croissante de la protection de l'environnement mondial, le matériau des plateaux d'emballage industriel passe du plastique à la pâte. Les plateaux d'emballage industriel en pâte ont non seulement une certaine capacité de charge, mais sont également biodégradables et recyclables, ce qui en fait un bon choix pour le transport et l'emballage.

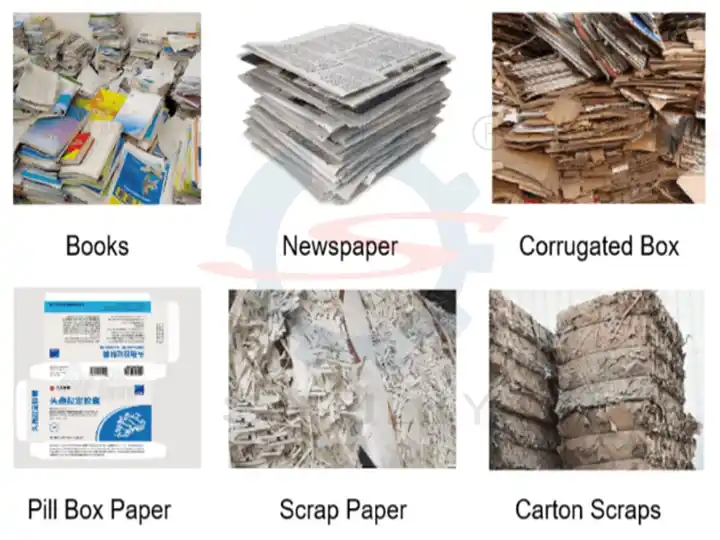

Matières premières recyclables

Les matières premières pour les plateaux d'emballage industriel comprennent divers papiers usagés, tels que les cartons usagés, les vieux journaux, les livres usagés, le carton usagé, le papier blanc usagé et les bacs à œufs usagés. Tous ceux-ci peuvent être utilisés pour fabriquer des plateaux en pâte.

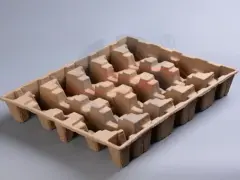

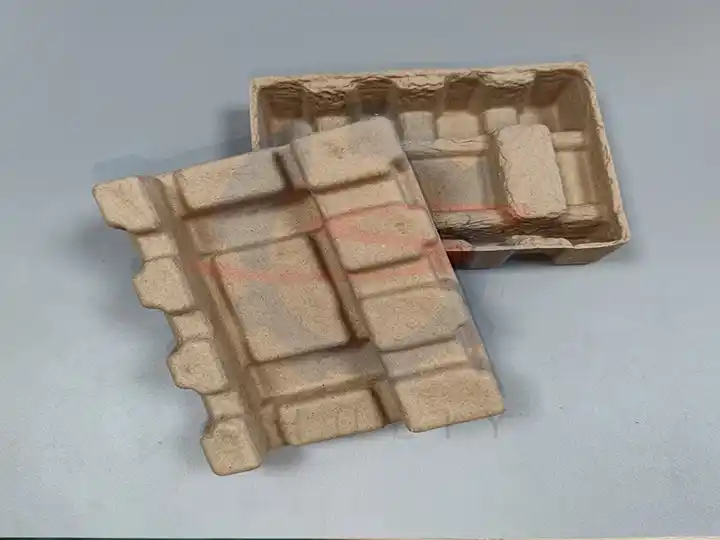

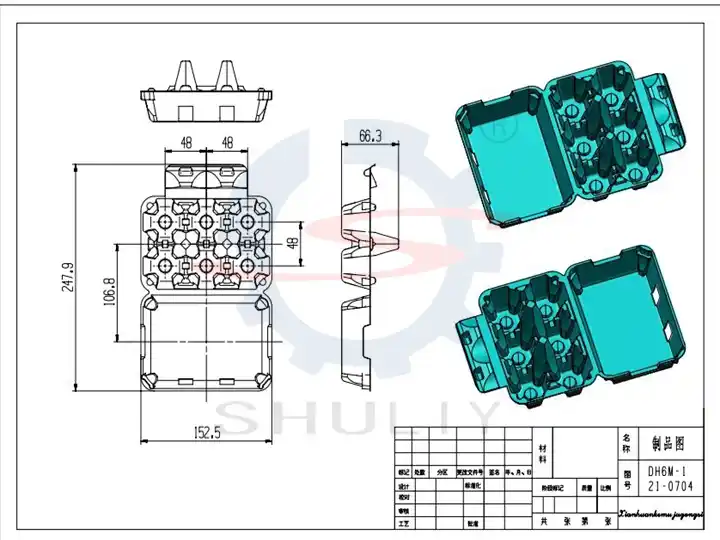

Affichage du produit final

Shuliy peut personnaliser différents types de plateaux d'emballage industriel. Nous pouvons fournir des dessins 3D pour concevoir le type de plateau que vous souhaitez jusqu'à ce que vous soyez satisfait, et tous ces services sont gratuits.

Avantages de la machine de formage de plateaux d'emballage industriel

Écologique et biodégradable

Fabriqués à partir de matériaux de pâte largement disponibles tels que les cartons usagés, les journaux, les livres usagés, le carton et les chutes de papier. Les plateaux sont peu coûteux, recyclables et naturellement dégradables.

Haute capacité de charge et absorption des chocs

Peut résister à la pression et aux vibrations pendant le transport des produits industriels, garantissant la sécurité des pièces internes.

Capacité de production élevée

La sortie d'une seule machine atteint 1 000 à 2 000 pièces/h.

Conception de plateau personnalisée

La taille, les compartiments et l'épaisseur du plateau peuvent être adaptés aux besoins du produit. Shuliy fournit également une assistance à la conception 3D.

Contrôle automatisé

Le contrôle intelligent PLC permet le formage, le séchage, le démoulage et l'empilage entièrement automatiques, améliorant l'efficacité de la production.

Facile à stocker

Plus petit en volume que la mousse, les plateaux peuvent être empilés à plusieurs reprises pour un stockage et un transport pratiques.

Ligne de production entièrement automatique

Le traitement de la pâte, le formage, le démoulage, le transport, le séchage et l'empilage peuvent être entièrement automatisés, particulièrement adaptés aux commandes d'exportation et aux projets OEM/ODM.

Durable avec des matériaux de première qualité

Les pièces clés sont en acier 40Cr et en acier inoxydable 304. La durée de vie peut atteindre plus de 10 ans.

Modèles de la machine de fabrication de plateaux d'emballage industriel

Shuliy propose principalement un modèle de machine de fabrication de plateaux d'emballage industriel. Si vous avez d'autres exigences, vous pouvez également nous contacter pour une consultation.

| Modèle | SL-R2000 |

| Capacité | 1000-2000pcs/h |

| Puissance | 55kw |

| Tension | 380V,50HZ |

| Utilisation de pulpe | 200kg/h |

| Utilisation d'eau | 400kg/h |

| Taille (mm) | 2900*1800*1800 |

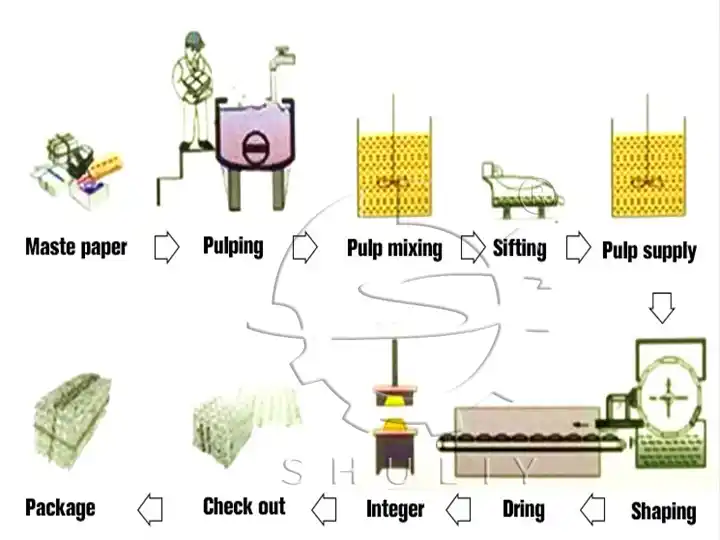

Principe de fonctionnement et processus

La machine de moulage de plateaux d'emballage industriel Shuliy utilise une technologie avancée de moulage de pâte. Son principe de fonctionnement et son processus principal sont les suivants :

Principe de fonctionnement

- Le moule se déplace d'avant en arrière dans le réservoir de pâte, utilisant une aspiration sous vide pour fixer les fibres de pâte à la surface du moule.

- Le moule est soulevé pour éliminer l'excès d'eau.

- Un moule de transfert déplace le flan de plateau humide vers le système de séchage.

- Enfin, le plateau est entièrement formé.

Processus principal

- Système de pulpage: Les vieux papiers bruts sont mis en pâte à l'aide d'une désintégration hydraulique et battus jusqu'à une concentration de pâte spécifique.

- Moulage alternatif : Le moule de formage se déplace d'avant en arrière dans le réservoir de pâte. Grâce à une aspiration sous vide, les fibres de pâte sont fixées uniformément à la surface du moule, formant un flan de plateau humide.

- Transfert et démoulage : Après que le moule de formage se soulève, il se connecte au moule de transfert. Le flan humide est déplacé vers l'étape de séchage à l'aide d'air comprimé ou de moyens mécaniques.

- Séchage et solidification: Le flan humide entre dans le canal de séchage ou l'unité de pressage à chaud pour une déshydratation et une solidification rapides, produisant le plateau fini.

- Mise en forme et empilage : Selon les exigences du client, un pressage à chaud secondaire peut être appliqué pour garantir la précision dimensionnelle et la douceur de la surface, suivi de l'empilage et de l'emballage.

Domaines d'application

Les plateaux produits par la machine de moulage de plateaux d'emballage industriel Shuliy peuvent être utilisés dans diverses industries :

- Électronique : cartes de circuits imprimés, capteurs, batteries, chargeurs, accessoires de téléphone portable, etc.

- Machines : engrenages, roulements, vis, outils à main et pièces de quincaillerie.

- Automobile : feux de voiture, pièces intérieures, tableaux de bord et autres composants.

- Optique et instruments de précision : lentilles, capteurs et composants optiques.

- Produits pharmaceutiques et alimentaires : bouteilles de médicaments, compléments alimentaires et petits plateaux d'emballage alimentaire.

Avez-vous des produits que vous souhaitez emballer ? Vous voulez savoir si vos produits conviennent à cette machine ? Vous êtes invités à nous consulter. Vous pouvez fournir des photos des produits que vous souhaitez emballer, et nous vous donnerons des conseils gratuits.

Moulage alternatif vs. Moulage par tambour rotatif

Notre machine utilise le processus de moulage alternatif, tandis que nos autres produits, tels que les machines à bacs à œufs et les machines de formage de plateaux à fruits, utilisent le processus de moulage par tambour rotatif. Voici la différence entre les deux machines.

Machine de moulage alternatif

Principe de fonctionnement

Le moule de formage se déplace d'avant en arrière dans le réservoir de pâte. L'aspiration sous vide dépose les fibres de pâte sur la surface du moule, suivie d'une déshydratation, d'un transfert et d'un séchage.

Caractéristiques

- Convient aux plateaux d'emballage industriel de grande taille, à cavité profonde et aux emballages de composants de précision.

- Remplacement flexible des moules, prenant en charge diverses conceptions personnalisées.

- Structure relativement simple, facile à entretenir.

- Haute capacité de charge et forte résistance à la pression.

- Capacité de production moyenne : 1 000 à 2 000 pièces/h.

- Le coût d'investissement est relativement plus élevé.

Machine de moulage par tambour rotatif

Principe de fonctionnement

Un ou plusieurs moules sont fixés sur un tambour rotatif. Le tambour tourne en continu et les moules entrent séquentiellement dans le réservoir de pâte pour l'aspiration, le moulage sous vide, la déshydratation et le transfert, réalisant une production continue.

Caractéristiques

- Convient aux produits à grande échelle, standardisés et à usage unique, tels que les bacs à œufs, les plateaux à fruits et les contenants alimentaires.

- Production continue avec une haute efficacité et un rendement élevé.

- Capacité de charge plus faible.

- Haute capacité de production : 1 000 à 7 000 pièces/h.

- Le coût d'investissement est relativement plus faible.

Services et support fournis par Shuliy

- Fabrication de précision : Traité et soudé à l'aide de machines CNC de haute précision.

- Contrôle qualité strict : Chaque machine subit des tests de contrôle électrique, une inspection de la précision des moules, des essais et des tests de fonctionnement avant la livraison.

- Support d'installation professionnelle : Nos ingénieurs peuvent être dépêchés pour l'installation sur site, le débogage et les essais.

- Solutions complètes : De la consultation pré-vente et 3D la conception de dessins à la livraison de processus complets, nous fournissons un support de service complet.

- Production complète de pièces de rechange : Chaque fois que vous avez besoin de pièces, nous pouvons les préparer en fonction du modèle de la machine que vous avez achetée.

- Excellent service après-vente : les responsables de la livraison résolvent rapidement les problèmes opérationnels et maintiennent une communication active avec vous. La machine est livrée avec une garantie de 1 an.

Partenariat avec Shuliy

Si vous avez besoin d'une machine d'emballage industrielle professionnelle pour la production de plateaux d'emballage industriel, la machine de fabrication de plateaux d'emballage industriel Shuliy est votre meilleur choix. Nos machines offrent un excellent rapport coût-performance, vous aidant à réussir votre entreprise et à obtenir un retour sur investissement solide.

Si vous souhaitez en savoir plus sur les prochaines étapes de votre entreprise, n'hésitez pas à me contacter, et je vous fournirai des informations plus détaillées.