Máquina para hacer bandejas de vino de pulpa | máquina para hacer bandejas de embalaje de vino

| Marca | Maquinaria Shuliy |

| Modelo | Serie SL |

| Capacidad | 1000-7000pcs/h |

| Potencia | 38-120kw |

| Voltaje | 380V,50HZ |

| Tamaño | Tabla de Parámetros Técnicos de Referencia |

| Garantía | 12 meses |

Ahora puedes preguntar a nuestros gerentes de proyecto por detalles técnicos

Una máquina de fabricación de bandejas de vino de pulpa es un equipo industrial diseñado para producir bandejas de vino de pulpa moldeada. Utiliza procesos como el moldeo al vacío, el prensado y el secado para dar forma a la pulpa en varios diseños de bandejas.

Las bandejas de vino de pulpa son materiales de embalaje ecológicos hechos de papel de desecho, cartones y materiales similares utilizando tecnología de moldeo por pulpa. En comparación con el embalaje de espuma tradicional, las bandejas de vino de pulpa son más ecológicas, biodegradables y ofrecen un buen acolchado, lo que las convierte en una mejor opción para las necesidades modernas de embalaje verde.

Esta máquina de fabricación de bandejas de envasado de vino desempeña un papel importante en las líneas de producción de envasado ecológico moderno, y es especialmente adecuada para fabricar bandejas para botellas de vidrio como vino, champán, y licor.

Shuliy ofrece 7 modelos de máquinas de moldeo por pulpa con una capacidad de 1,000 a 7,000 uds/h, exportando más de 50 unidades por año.

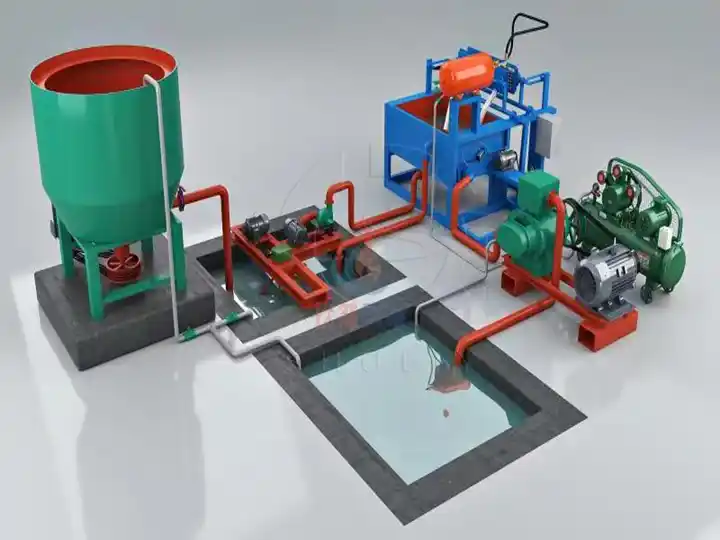

Estructura principal de la máquina para fabricar bandejas de vino de pulpa

La máquina de fabricación de bandejas de pulpa para vino incluye principalmente el sistema de pulpeo, sistema de conformado, sistema de secado y sistema de envasado.

- Sistema de pulpeo: Esto incluye un triturador, un tanque de agua y un mezclador. Mezcla papel desechado con agua para hacer pulpa suave. Está conectado a un dispositivo de control de concentración de pulpa.

- Sistema de formación: Esto utiliza moldes de succión para dar forma a la pulpa bajo presión negativa. El molde consta de partes superior e inferior, que se pueden cambiar rápidamente para adaptarse a diferentes bandejas de botellas de vino. El accionamiento de formación puede ser hidráulico o neumático.

- Sistema de Secado: Después de formarse, las bandejas húmedas se secan a altas temperaturas. Hay seis métodos de secado para elegir: secado natural, horno de secado, sala de secado de ladrillo o secado metálico de múltiples capas. Esto asegura que las bandejas sean estables en tamaño y suaves en la superficie.

- Sistema de Embalaje: Las bandejas se pueden contar y apilar utilizando un apilador, luego empaquetadas para su entrega.

Parámetros técnicos de la máquina para fabricar bandejas de vino de pulpa Shuliy

| Modelo | Capacidad | Potencia | Voltaje | Peso | Uso de Pulpa | Uso de Agua | Tamaño (mm) |

| SL-1000-3X1 | 1000pcs/h | 38kw | 380V,50HZ | 2500kg | 80kg/h | 160kg/h | 2600*2200*1900 |

| SL-1500-4X1 | 1500pcs/h | 38kw | 380V,50HZ | 3000kg | 120kg/h | 240kg/h | 2800*2200*1900 |

| SL-2500-3X4 | 2500pcs/h | 55kw | 380V,50HZ | 4000kg | 200kg/h | 400kg/h | 2900*1800*1800 |

| SL-3000-4X4 | 3000 piezas/h | 60 kW | 380V,50HZ | 4800 kg | 240kg/h | 480kg/h | 3250*1800*1800 |

| SL-4000-4X8 | 4000 piezas/h | 95kw | 380V,50HZ | 7000kg | 320kg/h | 640kg/h | 3250*2300*2500 |

| SL-5000-5X8 | 5000pcs/h | 95kw | 380V,50HZ | 8000kg | 400kg/h | 800kg/h | 3700*2300*2500 |

| SL-7000-6X8 | 7000pcs/h | 120kw | 380V,50HZ | 10000kg | 480kg/h | 960kg/h | 3200*2300*2500 |

Lo anterior es nuestro modelo estándar para referencia. Si tiene requisitos más específicos, también podemos personalizar la máquina según sus necesidades.

¿Cómo funciona la máquina formadora de bandejas de vino de pulpa?

Similar a la máquina de fabricación de bandejas de huevo, la máquina de conformado de bandejas de vino de pulpa adopta la tecnología de conformado por pulpa. Sigue un proceso de conformado de pulpa donde la pulpa se inyecta en un molde. Luego, la bandeja se forma por succión al vacío, se seca con calor y se fabrica en una bandeja de resistencia y diseño especiales.

Los principales pasos de trabajo también son: pulpeo → formación → secado → embalaje.

Ventajas de la máquina para fabricar bandejas de embalaje de vino Shuliy

- Alta automatización: Desde el pulpeo hasta la formación, recorte y embalaje, el proceso es automático, ahorrando costos laborales.

- Producción ecológica: No hay emisiones de aguas residuales ni de gases. Las materias primas pueden ser recicladas nuevamente, cumpliendo con las políticas ambientales locales.

- Moldes personalizados: Adecuado para diferentes tamaños y tipos de botellas (como Bordeaux, champán, botellas de licor). También podemos personalizar moldes según las botellas que nos envíes.

- Bonito acabado superficial: Las bandejas lucen suaves y limpias, perfectas para cajas de regalo de vino premium o exhibiciones en showroom. Puedes personalizar el color, el grabado del logo o los patrones para mejorar tu embalaje.

- Múltiples opciones de bandejas: Puede producir bandejas para 1, 2, 6 o 12 botellas.

- Rendimiento estable: Controla con precisión la presión de formación, el tiempo y el ajuste del molde para garantizar una calidad consistente. En comparación con las máquinas normales, puede funcionar 2.5 veces más.

- Sistema de moldes de alta precisión: Hace que las bandejas sean más fuertes y estables, con buen soporte de peso y sin bordes deformados. La bandeja tiene puntos de soporte simétricos para un mejor rendimiento.

- Servicios personalizados disponibles: Ofrecemos diseño basado en muestras, coincidencia de tamaño de botellas, estampado de logotipos, personalización de colores y más para ayudar a que su marca se destaque. Se pueden proporcionar soluciones de embalaje integrales con la máquina formadora de bandejas.

- Línea de producción completa y solución disponible: Como fabricante directo, podemos proporcionar máquinas de pulpa, compresores de aire, secadores y otro equipo. También ofrecemos una planificación razonable del diseño del terreno para ayudar a reducir sus costos laborales.

¿Cuáles son los tipos de bandejas de vino de pulpa?

| Categoría | Tipo |

| Por volumen de botella | 187ml, 375ml, 500ml, 700ml, 750ml, 1L, 1.5L, 3L / 5L |

| Por cantidad de botellas | Botella única, Dos botellas, Cuatro botellas, Seis botellas, Doce botellas |

| Por estructura | Tipo de una pieza, Tipo separado de arriba y abajo, Tipo insertable |

| Por proceso de moldeo | Moldeo por prensado en seco, Moldeo por prensado en húmedo |

| Por uso | Tipo de protección durante el transporte, Tipo de exhibición en caja de regalo, Tipo de exportación |

¿Por qué elegir una máquina para hacer bandejas de embalaje de vino?

Tiene amplias aplicaciones:

- Fabricantes de vino: Utilizado para el embalaje interior de productos de vino embotellado.

- Plataformas de comercio electrónico: Ideal para el envío seguro de una o varias botellas de vino.

- Empresas de empaquetado de regalos: Utilizado para bandejas dentro de cajas de vino de regalo o conjuntos de vino premium.

- Comerciantes de exportación: Cumple con las regulaciones de empaques ecológicos en la UE, EE. UU. y otros países.

- Supermercados y tiendas minoristas: Utilizado para paquetes combinados, haciendo que la exhibición y las ventas sean más convenientes.

Ventajas en comparación con otros materiales de embalaje:

| Artículo | Bandeja de vino de pulpa | Bandeja de espuma de plástico | Inserto de papel corrugado |

| Ambiental | Biodegradable, ecológico | No biodegradable | Reciclable |

| Protección | Fuerte | Muy fuerte | Medio |

| Costo | Medio | Más alto | Bajo |

| Personalización | Alto | Medio | Medio |

| Apariencia | Bueno (mejor con prensado en húmedo) | Pobre | Medio |

Productos terminados de la máquina para fabricar bandejas de vino de pulpa

Las bandejas de vino de pulpa que producimos a menudo se muestran a continuación. Sin embargo, tenemos muchas otras opciones de moldes disponibles. Si estás interesado, ¡no dudes en contactarnos en cualquier momento!

Envío de la máquina para hacer bandejas de pulpa para vino

Aquí hay algunas de nuestras fotos de envío. Puedes echar un vistazo a nuestro empaque.