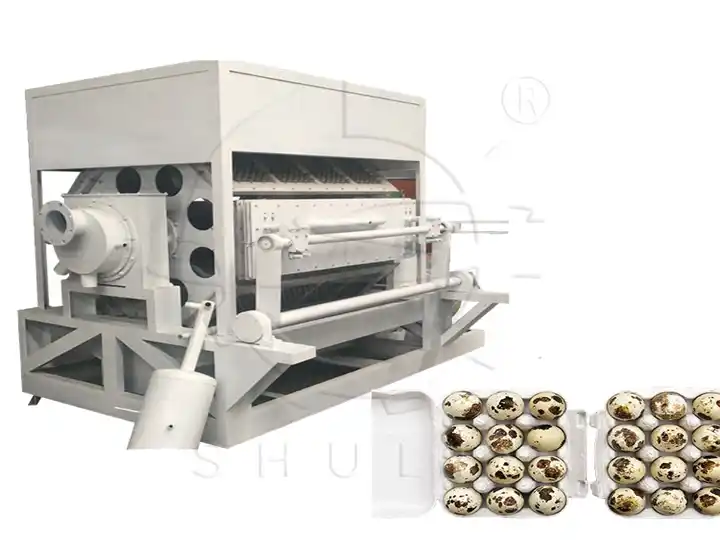

Wachtel-Eierplatten-Herstellungsmaschine

| Modell | SL-2500-3X4 |

| Kapazität | 2500Stück/h |

| Leistung | 55kW |

| Spannung | 380V, 50HZ |

| Größe (Spritzgießmaschine) | 2900*1800*1800mm |

| Papierverbrauch | 200kg/h |

| Wasserverbrauch | 400kg/h |

Sie können jetzt unsere Projektmanager nach technischen Details fragen.

Die Maschine zur Herstellung von Wachtel-Ei-Trays ist eine Formgebungsanlage, die speziell zur Produktion von Wachtel-Ei-Trays entwickelt wurde. Sie funktioniert, indem Abfallpapier, Wasser und Zusatzstoffe zu einer Pulpe gemischt werden, die dann durch Formen, Entwässern, Trocknen und Heißpressen in die Tray-Form gebracht wird. Die Trays bestehen aus Papierpulpe und werden verwendet, um Wachtel-Eier zu verpacken und zu schützen.

Die produzierten Wachtelei-Behälter bestehen hauptsächlich aus recyceltem Papierbrei, der biologisch abbaubar oder recycelbar ist und den umweltfreundlichen Standards entspricht. Sie sind für den Export und die Anforderungen des modernen Marktes geeignet.

Unser Unternehmen bietet verschiedene Produktionskapazitäten und unterschiedliche Spezifikationen von Maschinen zur Herstellung von Wachtel-Ei-Trays an, die sich sowohl für die großflächige Produktion und den Verkauf als auch für die Exportbedürfnisse von Wachtel-Eiern eignen. Wir haben in über 10 Länder exportiert, darunter die Philippinen, Vietnam, Japan, Indonesien, Saudi-Arabien und Frankreich.

Hauptstruktur der Herstellung von Wachtel-Ei-Tabletts

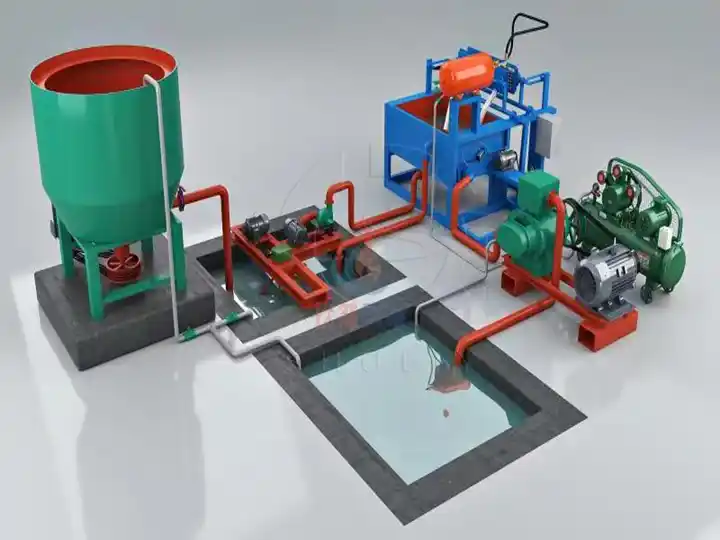

Ähnlich wie bei Hühner-Ei-Tablettmaschinen umfassen die Hauptkomponenten der Wachtel-Ei-Tablett-Herstellungsmaschine:

- Zellstoffsystem: Enthält Pulper, Mischbehälter und Pulppumpe, die zur Rohstoffaufbereitung verwendet werden.

- Schalenformsystem: Die Kernformungsgeräte mit Formen und Antriebseinheiten. Formen können gewechselt werden, um Wachtel-Ei-Tabletts unterschiedlicher Größen herzustellen.

- Schalen-Trocknungssystem: Verwendet normalerweise natürliche Trocknung, Trockenschrank, Ziegeltrocknungsraum oder mehrschichtige Metalltrocknung.

- Tablett-Verpackungssystem: Verwendet Stapel- und Verpackungsmaschinen zum Zählen und Stapeln, um die Verpackung und den Transport des Fertigprodukts zu erleichtern.

Modelle und Parameter von Wachtel-Ei-Tablett-Herstellungsmaschinen

| Modell | Kapazität | Leistung | Spannung | Gewicht | Papierverbrauch | Wasserverbrauch | Größe (Spritzgießmaschine) |

| SL-1000-3X1 | 1000 Stück/h | 38 kW | 380V, 50HZ | 2500 kg | 80 kg/h | 160 kg/h | 2600*2200*1900mm |

| SL-1500-4X1 | 1500 Stück/Stunde | 38 kW | 380V, 50HZ | 3000 kg | 120 kg/Stunde | 240 kg/Stunde | 2800*2200*1900mm |

| SL-2500-3X4 | 2500Stück/h | 55kW | 380V, 50HZ | 4000kg | 200kg/h | 400kg/h | 2900*1800*1800mm |

| SL-3000-4X4 | 3000Stück/h | 60kW | 380V, 50HZ | 4800kg | 240 kg/Stunde | 480kg/h | 3250*1800*1800mm |

| SL-4000-4X8 | 4000Stück/h | 95kW | 380V, 50HZ | 7000kg | 320kg/h | 640kg/h | 3250*2300*2500mm |

| SL-5000-5X8 | 5000 Stück/h | 95kW | 380V, 50HZ | 8000 kg | 400kg/h | 800 kg/h | 3700*2300*2500mm |

| SL-7000-6X8 | 7000 Stück/Stunde | 120 kW | 380V, 50HZ | 10000 kg | 480kg/h | 960 kg/Stunde | 3200*2300*2500mm |

Die oben genannten sind unsere Standardmodelle zu Ihrer Referenz. Wenn Sie spezifische Anforderungen haben, können wir Maschinen nach Ihren Bedürfnissen anpassen.

Warum die Shuliy Wachtel-Ei-Behältermaschine wählen?

- Flexible Anpassung: Formgröße, Kapazität und Heizmethode (Strom, Erdgas, Diesel) können kostengünstig nach den Kundenbedürfnissen angepasst werden.

- Hohe Automatisierung: Vom Schreddern, Formen, Trocknen bis hin zum Verpacken kann der gesamte Prozess vollständig automatisiert werden, um Arbeitskosten zu sparen.

- Hohe Formenpräzision: Die Tabletts sind stärker und stabiler, ohne verzogene Kanten, und passen perfekt zu Wachtel-Eiern. Die Tabletts haben eine moderate Dicke, wodurch sie leicht, aber dennoch stabil sind.

- Intelligentes Zellstoffabsaugsteuerungssystem: Sorgt für eine gleichmäßige Pulpaussaugung in jeder Formhohlraum.

- Professionelles Trocknungsliniensystem: Sorgt für gleichmäßiges und schnelles Trocknen der Tabletts.

- Professionelle Anpassung von Wachtel-Ei-Tablettformen: Garantiert präzise Größe und vernünftige Anordnung.

Anwendungen der Wachtel-Ei-Behältermaschine

- Wachtelfarmen

- Eiersortierzentren/Ei-Verarbeitungsanlagen

- Papier-Tablett-Verpackungsfabriken

- Agrarmärkte / Großmärkte

- E-Commerce und frische Lebensmittel-Lieferunternehmen

- Supermärkte und Einzelhandelsgeschäfte

- Exporthandelsunternehmen

Wie funktioniert die Wachtel-Ei-Behälterformmaschine?

Der Arbeitsablauf kann vereinfacht werden als: Altpapier → Pulpeherstellung → Pulpe-Saug-Formgebung → Entformung → Trocknung → Formgebung → Verpackung

- Rohmaterialaufbereitung: Altpapier wird zerkleinert und mit Wasser gemischt, um eine gleichmäßige Pulpe zu bilden, die für die Formung vorbereitet wird.

- Pulpaussaugformung: Die Form wird in den Pulpetank eingetaucht, und die Vakuumsaugung zieht die Pulpe auf die Oberseite der Form. Dies ist der Schlüsselprozess der Maschine.

- Entformen und Transfer: Nach der Formung werden die nassen Tabletts pneumatisch oder mechanisch aus den Formen entfernt.

- Trocknung: Natürliche Trocknung oder Trocknungsgeräte können verwendet werden.

- Zählen, Stapeln und Verpacken: Automatisches Zählen, Stapeln und Verpacken für einfachen Transport und Verkauf.

Wenn ein glatteres Aussehen und eine stärkere Festigkeit erforderlich sind, können die getrockneten Wachtel-Eier-Tabletts einem sekundären Heißpress- und Formungsprozess unterzogen werden.

Wartung und Vorsichtsmaßnahmen für die Wachtel-Ei-Tablettmaschine

- Tägliche Wartung: Nach der täglichen Produktion die Formen reinigen, das Pulssaugsystem überprüfen und Ketten, Führungen, Zylinder und Pleuel an den vorgesehenen Stellen schmieren.

- Wöchentliche Wartung: Überprüfen Sie den Verschleiß der Form, inspizieren Sie den Ölstand und die Qualität des Vakuumpumpenöls und wechseln Sie das Öl regelmäßig. Überprüfen Sie auch die Sensoren und Steuerungspaneele auf normale Funktion und überwachen Sie abnormalen Alarm.

- Monatliche Wartung: Überprüfen Sie den Motor, die Riemen und die Lager; ziehen Sie die Maschinenschrauben und -anschlüsse fest.

- Vorsichtsmaßnahmen: Demontieren Sie die Geräte nicht ohne Fachkenntnisse. Bei einem Fehler wenden Sie sich bitte an den technischen Support nach dem Verkauf. Verwenden Sie nur Originalteile für den Austausch.

Arten von Wachtel-Ei-Behältern

| Kapazität | Anwendung | Material |

| 10-Ei-Tray | Einzelhandelsdisplay-Tray | Pulpgeformt |

| 20/30-Ei-Tray | Transport-Tray | Kunststoff |

| 60 Eier und mehr | Einweg-Exportplatte | Schaum |

Pulpmoldierte Wachtelei-Trays sind die gebräuchlichsten. Sie sind leicht, feuchtigkeitsabsorbierend und atmungsaktiv, mit anpassbaren Druckoptionen. Diese Trays werden häufig in Farmen, Supermärkten, im E-Commerce und in anderen Bereichen eingesetzt.

Fertiges Produktdisplay für Wachtel-Ei-Schalen

Unten sind Referenzbilder unserer Standardprodukte für Wachtel-Ei-Trays.

Exportfall für Wachtel-Ei-Schalen-Herstellungsmaschine

Kooperieren Sie mit uns

Bei Interesse kontaktieren Sie uns einfach direkt für Details per WhatsApp: https://wa.me/+8619139761487