蛋盒模具使用了哪些材料?

在纸浆蛋托生产中,蛋托模具是核心设备之一。它直接影响成型质量、生产效率和成本。不同的模具材料在导热性、耐磨性、加工成本和维护便利性方面各有特点。本文将系统介绍蛋托模具的材料及影响材料选择的因素。

蛋盒模具使用了哪些材料?

蛋托模具最常用的材料是 铝合金、不锈钢和塑料。其他复合或金属模具较少见,因此在此不作讨论。以下是对这三种常用材料的简要介绍。

铝合金 模具s

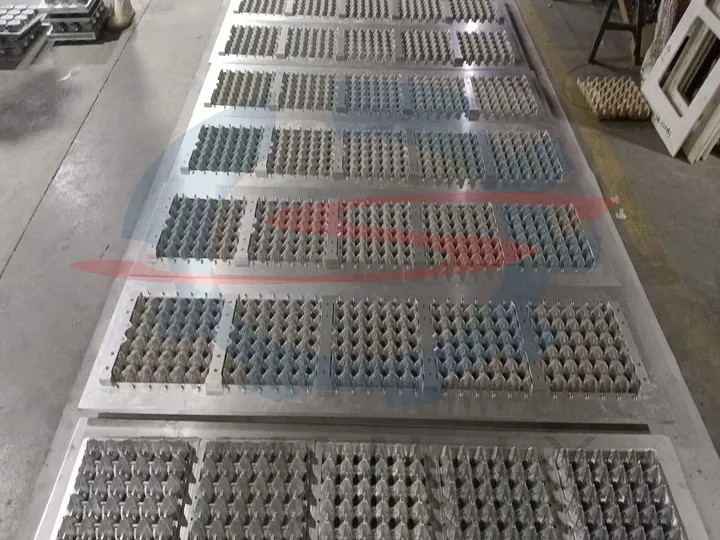

铝合金是目前最常用和最广泛的蛋托模具材料。铝材轻巧,导热性好,易于加工成型,而且比不锈钢便宜得多。因此,许多客户选择铝合金。舒利也提供半铝、半不锈钢模具或在特定区域采用定制材料的模具,以确保最佳的性价比。

铝合金蛋托模具的主要优势:

- 良好的导热性: 帮助水分快速排出,提高成型效率。

- 易加工: 适合CNC或线切割精密加工。

- 高性价比: 耐用性与制造成本之间的良好平衡。

- 轻巧: 易于安装和更换。

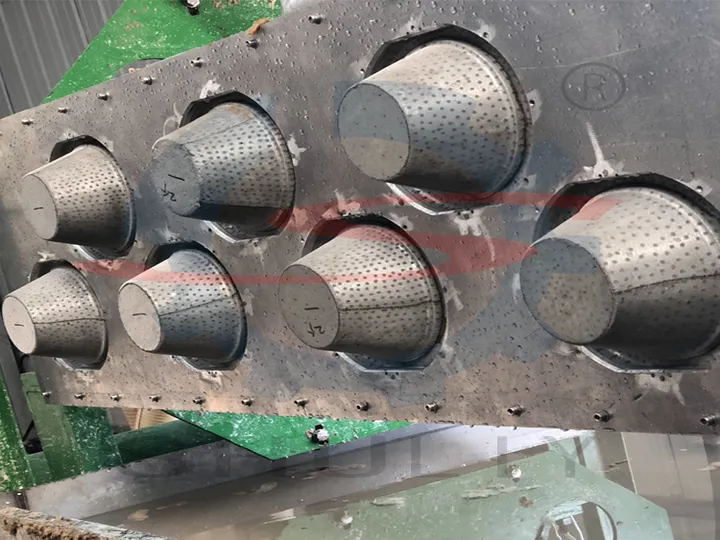

不锈钢模具

不锈钢模具的主要特点是强耐腐蚀性和高强度,适用于潮湿环境和长期连续生产。与铝合金相比,不锈钢更适合长期高强度生产任务,但成本较高。

不锈钢模具的主要优势:

- 耐腐蚀: 长时间接触水和浆料不易生锈。

- 高强度: 抗变形和耐磨性能强。

- 使用寿命长: 整体耐用,维护成本较低。

缺点:

- 比铝合金成本更高,加工难度更大。

塑料模具

蛋托模具也可以用塑料制造。塑料模具加工周期短,成本相对较低,但在长期生产中耐磨性和成型精度较弱。

塑料模具的主要优势:

- 投资低

- 轻巧,易于制造

- 高更换频率,价格实惠

缺点:

- 耐磨性差

- 易变形,使用寿命短

三种模具材料对比表

| 材料 | 成本 | 热导率 | 耐腐蚀性 | 加工难度 | 适用范围 |

|---|---|---|---|---|---|

| 铝合金 | 中等 | 良好 | 良好 | 易于 | 中高产量,主流使用 |

| 不锈钢 | 高 | 中等 | 优秀 | 中等到困难 | 高湿度、重负荷生产 |

| 塑料 | 低 | 差 | 中等 | 易于 | 试产/小批量 |

如何选择合适的蛋托模具材料?

在选择蛋托模具材料时,应考虑生产强度、工作环境和长期成本。

- 铝合金模具: 性能平衡,性价比高,适合大多数商业蛋托生产。

- 不锈钢模具: 耐腐蚀且持久,适合高湿或连续生产。

- 塑料模具: 投资低但耐用性有限,适合试运行或小规模生产。

为了在成本和耐用性之间取得平衡,也可以选择半铝合金/半不锈钢或定制本地材料选项,以实现最佳的性价比。

如何定制蛋托模具?

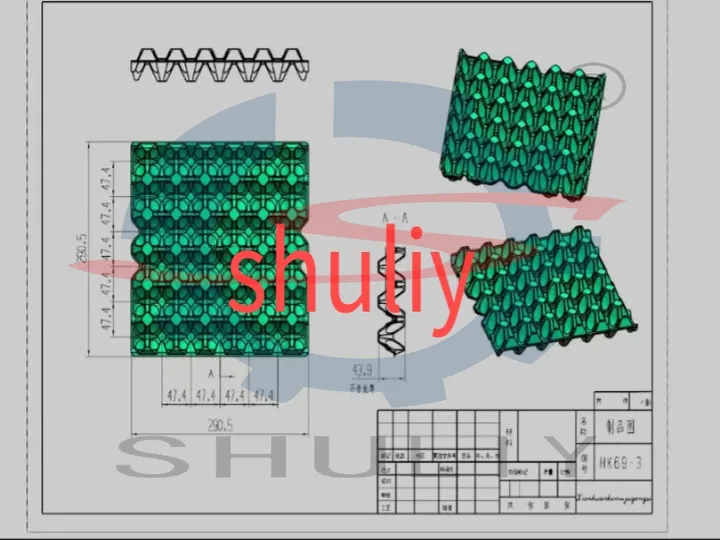

- 确定尺寸: 根据蛋位数和整体托盘尺寸设计蛋托。

- 选择材料: 铝合金、不锈钢或组合。

- 设计堆叠方式: 单层或堆叠结构。

- 定制外观: 加固边缘、标志压花或特殊功能。

- 提供规格或样品: 有助于模具设计和加工。

- 确认设计方案: 供应商通常提供3D渲染图或图纸;在生产前确认。

- 加工与检测: 模具生产后,测试样品以确保尺寸和成型效率。

舒利纸浆蛋托模具定制服务

舒利提供专业蛋托模具定制,灵活调整托盘尺寸、材料和样式,以满足客户需求。无论是标准的30个蛋的托盘还是较小的零售包装,我们都提供定制设计。

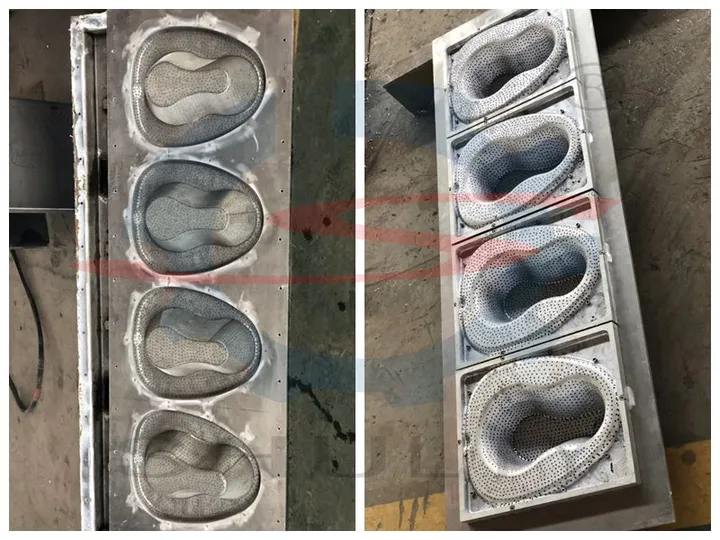

除了常规蛋托外,我们还支持定制鞋托、拖鞋托、水果托、育苗盘等模具。客户可以选择铝合金、不锈钢或组合材料,以确保最佳性价比,同时满足生产效率和产品质量要求。

舒利也提供外观定制,例如压花品牌标志、凸起边缘或特殊结构设计,以满足多样的市场和品牌需求。

蛋托成品展示