如何定制鹌鹑蛋托

众所周知,随着鹌鹑养殖的增长和对多样化蛋制品需求的增加,鹌鹑蛋在家庭、食品行业和出口市场上变得越来越受欢迎。然而,鹌鹑蛋体积小、易碎且壳薄。传统的大宗运输方式往往会导致破损、污染和浪费。

为了解决这个问题,开发了鹌鹑蛋托盘。这些托盘专门设计了合适的隔间和缓冲材料,以牢固地固定蛋,防止在运输过程中碰撞,并大大减少损坏。它们由纸浆制成,环保、可生物降解,并且可以定制,迅速成为主流包装选择。

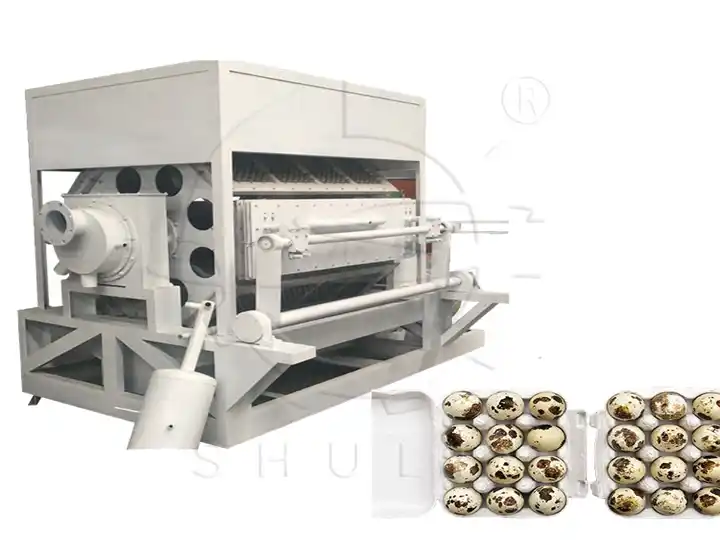

为解决这一点,我们开发了一款专用的鹌鹑蛋托盘制造机,通过专注于鹌鹑蛋托盘的设计与定制并结合先进的模具技术。

鹌鹑蛋托的广泛应用

- 鹌鹑养殖场适用于小型和大型农场,以安全地分类、包装和运输每日收集的蛋。

- 蛋分类中心/蛋加工厂: 使用纸质鹌鹑蛋托盘可以增加价值并改善品牌形象,同时确保安全处理。

- 纸浆包装厂: 制造商可以大规模生产鹌鹑蛋托盘,并将其供应给农场、超市和电子商务平台。

- 农业市场/批发市场: 改善产品展示,使堆叠和运输更容易,并保持蛋的清洁和保护。

- 电子商务和生鲜食品配送公司: 纸托盘与纸箱结合使用,可以在运输过程中保护鹌鹑蛋,减少损坏。

- 超市和零售店: 可以直接用于货架展示。它们环保、美观,并且方便顾客。

- 出口公司: 纸浆托盘符合国际环境标准,非常适合鹌鹑蛋出口包装。

鹌鹑蛋托的典型定制流程

需求确认 → 模具设计 → 样品测试 → 客户批准 → 调整 → 批量生产 → 打包与交付

定制鹌鹑蛋托盘时需要考虑的关键点

精确尺寸

鹌鹑蛋很小(直径2-3厘米)。托盘尺寸必须完全合适,以避免摇晃或卡住。

专业模具设计

孔布局必须紧密平滑,以防止壳体损坏。需要高精度。

均衡的托盘厚度

托盘应轻便但足够坚固。太薄会塌陷;太厚会增加成本和干燥时间。

透气且防潮

纸浆材料应能吸收水分并允许空气流通,以防止霉菌或异味。

多腔布局

常见类型:30、60或90个单元。这需要仔细的模具布局和准确的纸浆成型。

托盘盖一体化设计

一些客户更喜欢带盖的托盘。这需要更先进的模具和机器协调。

鹌鹑蛋托生产中的常见挑战

- 难以成型设计: 鹌鹑托盘模具小而密集。许多常规模具制造商无法实现准确的纸浆吸附,导致缺陷。

- 低纸浆吸取精度: 小模具需要更精确地控制真空时间和压力,以避免托盘不完整或不均匀。

- 脱模问题: 深而密集的模具可能导致托盘撕裂或粘连,从而降低产量。

- 干燥挑战: 更多单元=更密集的托盘。不均匀的热空气流动可能导致中心潮湿和边缘过干。

- 提高生产能力的困难: 标准蛋托机是为鸡蛋设计的。当用于高密度、多腔的鹌鹑蛋托时,生产能力显著下降,效率变得不稳定。

- 集成机器的兼容性差: 许多机器无法通过模具或夹紧系统进行改造,以生产带盖的鹌鹑蛋托,这使得切换到这种结构变得困难。

Shuliy推荐的解决方案

- 定制设计的鹌鹑蛋托模具,以确保精确的尺寸和最佳的布局。

- 智能纸浆吸取控制系统,以保证每个腔体的纸浆摄入量一致。

- 定制的更宽模具框架和多工位转盘设计,以提高密集结构的效率。

- 专业的干燥线系统,以确保均匀和快速的干燥。

- 可选的集成成型设计,以满足高端包装市场的需求。

与我们合作

如果您有兴趣,请直接通过WhatsApp联系我们获取详细信息:https://wa.me/+8619139761487