เครื่องผลิตถาดไข่ความเร็ว 2000-3000 เครื่อง/ชั่วโมง

| โมเดล | SL-3*4, SL-4*4 |

| ความจุ | 2000-3000 ชิ้น/ชั่วโมง |

| การใช้น้ำ | 400kg/h-480 kg/h |

| การใช้กระดาษ | 200-240kg/h |

| การรับประกัน | 12 เดือน |

คุณสามารถถามผู้จัดการโครงการของเราเกี่ยวกับรายละเอียดทางเทคนิคได้แล้ว

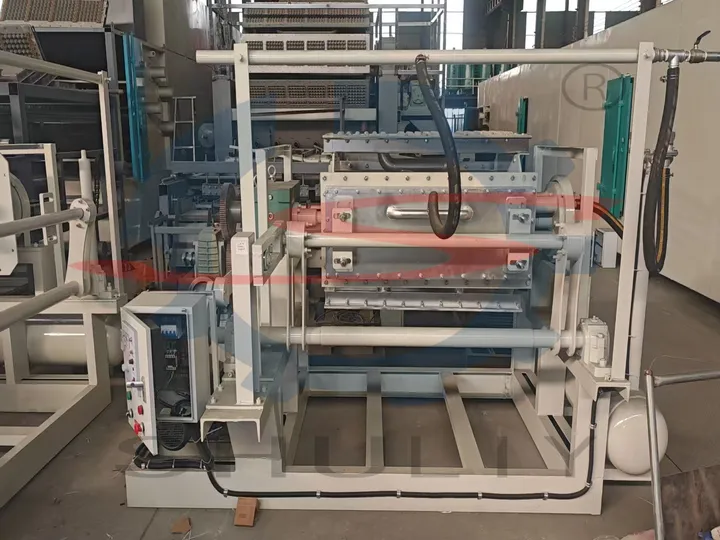

เครื่องผลิตถาดไข่ความจุ 2000–3000 ชิ้น/ชั่วโมง เรียกอีกอย่างว่า เครื่องหมุนแบบหลายด้าน ซึ่งเป็นเครื่องที่มีพื้นผิวขึ้นรูปหลายพื้นผิว สามารถผลิตถาดไข่ pulp ได้อย่างรวดเร็วและมีประสิทธิภาพ โดยผลผลิตต่อชั่วโมงอยู่ที่ 2,000–3,000 ชิ้น

Shuliy นำเสนอเครื่องผลิตถาดไข่ประเภทนี้ในสองรุ่น: SL-3*4 และ SL-4*4. รุ่น SL-3*4 มีผลผลิตอยู่ที่ 2,000–2,500 ชิ้นต่อชั่วโมง ในขณะที่รุ่น SL-4*4 ผลิต 2,500–3,000 ชิ้นต่อชั่วโมง เช่นเดียวกับเครื่องผลิตถาดไข่จากเยื่อกระดาษ pulp เครื่องนี้ใช้เยื่อกระดาษ pulp ในการผลิตถาดไข่

เครื่องผลิตถาดไข่ความจุกลางนี้เหมาะสำหรับโรงงานถาดไข่ขนาดเล็กหรือกลาง หากต้องการการผลิตในระดับใหญ่ สามารถเลือกเครื่องผลิตถาดไข่ที่มีความจุ 4,000–8,000 ชิ้น/ชั่วโมง ได้

เครื่องขึ้นรูปถาดไข่ความนิยมของ Shuliy ที่มีผลผลิต 2,000–3,000 ชิ้น/ชั่วโมง ดึงดูดลูกค้าจากกว่า 50 ประเทศและภูมิภาค รวมถึงบราซิล, สหรัฐอเมริกา, รัสเซีย, ซาอุดีอาระเบีย, ไนจีเรีย, กานา, และแอฟริกาใต้ ด้วยความทนทานและผลผลิตถาดไข่คุณภาพสูง

ทำไมเครื่องผลิตถาดไข่ 2,000–3,000 ชิ้น/ชั่วโมง ถึงเรียกว่า เครื่องหมุนแบบหลายด้าน?

เครื่องหมุนแบบหลายด้าน หมายถึง เครื่องผลิตถาดไข่ที่มีดีไซน์ถังหมุนในส่วนขึ้นรูป ถังเป็นส่วนสำคัญของเครื่องถาดไข่แบบหลายด้าน และโดยทั่วไปเป็นโครงสร้างทรงกระบอกหรือหลายเหลี่ยมที่หมุนได้

“หลายด้าน” หมายถึง ถาดมีพื้นผิวถ่ายโอนหลายพื้นผิว แต่ละพื้นผิวมีแม่พิมพ์ขึ้นรูปถาดไข่หลายแม่พิมพ์ หมุนอย่างต่อเนื่องเพื่อให้ได้ผลผลิตสูง เครื่องผลิตถาดไข่ 2,000–3,000 ชิ้น/ชั่วโมงนี้มีพื้นผิวขึ้นรูปสี่ด้าน

เครื่องถาดไข่แบบหลายด้านทั่วไปมี 4 หรือ 8 พื้นผิว เมื่อเทียบกับเครื่อง 8 ด้าน เครื่อง 4 พื้นผิวมีผลผลิตปานกลาง โครงสร้างกะทัดรัด ต้นทุนต่ำ และการใช้งานง่าย จึงเหมาะสำหรับโรงงานขนาดเล็กและกลาง

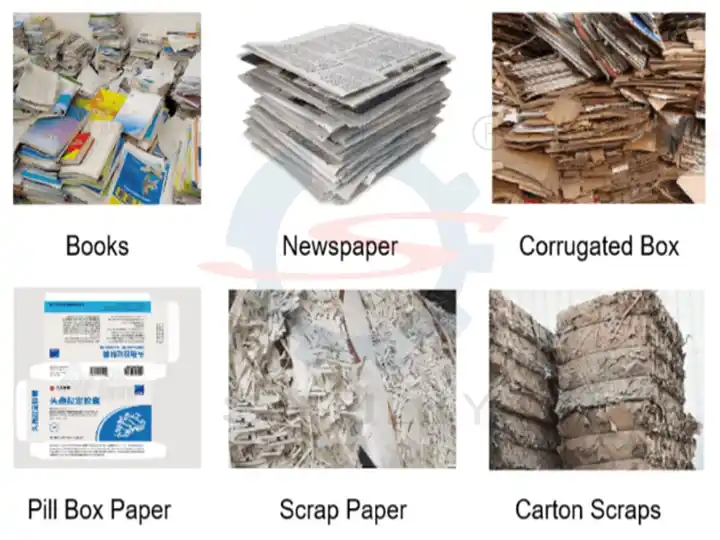

วัตถุดิบสำหรับถาดไข่ pulp คืออะไร

วัตถุดิบหลักที่ใช้กันทั่วไปคือ กระดาษรีดเก่าและน้ำ วัสดุอื่น ๆ อาจรวมถึงกระดาษคราฟท์, กระดาษลูกฟูก, และกล่องกระดาษ ซึ่งล้วนมีเส้นใย

ลูกค้าบางรายใช้เศษวัสดุจากโรงงานกระดาษ และบางรายใช้กระดาษรีดด้านเดียว วัสดุทั้งหมดต้องผสมกับน้ำและ pulp ก่อนการผลิต สัดส่วนเศษกระดาษต่อน้ำโดยทั่วไปคือ 1:10

ถาดไข่ที่ผลิตจากเศษกระดาษเหล่านี้เป็นมิตรกับสิ่งแวดล้อม ย่อยสลายได้ และทนทาน

หลักการทำงานของเครื่องผลิตถาดไข่ 2,000–3,000 ชิ้น/ชั่วโมง

เครื่องผลิตถาดไข่ 2,000–3,000 ชิ้น/ชั่วโมง มักใช้หลักการขึ้นรูปแบบหมุนบนถังหมุนในส่วนขึ้นรูป ระหว่างการทำงาน pulp จะถูกสูบเข้าแม่พิมพ์ขึ้นรูป ซึ่งขึ้นรูปถาดไข่บนถังหมุนเป็นลำดับ ถาดจะผ่านการบีบน้ำออก การกด และการอบแห้ง แล้วจึงปล่อยออกโดยสายพานลำเลียง กระบวนการทั้งหมดเป็นไปอย่างต่อเนื่องและมีประสิทธิภาพ โดยไม่ต้องแทรกแซงด้วยมือ จึงเหมาะสำหรับการผลิตถาดไข่ขนาดเล็กและกลาง

ประเภทของเครื่องถาดไข่ 2,000–3,000 ชิ้น/ชั่วโมง

ประเภท 1: SL-3*4

เครื่อง SL-3*4 มีพื้นผิวหมุน 4 พื้นผิวและพื้นผิวถ่ายโอน 1 พื้นผิว แต่ละพื้นผิวหมุนมีแม่พิมพ์ขึ้นรูป 3 แม่พิมพ์ พื้นผิวถ่ายโอนส่ง pulp ไปยังแม่พิมพ์ขึ้นรูป และแม่พิมพ์ทั้งสามขึ้นรูปถาดเปียกพร้อมกัน แต่ละรอบผลิตถาดไข่ 12 ชิ้น

ข้อมูลทางเทคนิค

| Parameter | ข้อมูลจำเพาะ |

|---|---|

| ผลผลิตต่อชั่วโมง | 2,500 ชิ้น |

| พลังงาน | 55 kW |

| แหล่งจ่ายไฟ | 380V 50Hz |

| น้ำหนัก | 4,000 กก. |

| ขนาดเครื่อง (L×W×H) | ขนาด 2,900×1,800×1,800 มม |

| การใช้กระดาษต่อชั่วโมง | 200 กก. |

| การใช้น้ำต่อชั่วโมง | 400 กก. |

| วิธีการอบแห้ง | เตาอิฐหรือหลายชั้น |

ประเภท 2: SL-4*4

เครื่อง SL-4*4 มีพื้นผิวหมุน 4 พื้นผิวและพื้นผิวถ่ายโอน 1 พื้นผิว แต่ละพื้นผิวหมุนมีแม่พิมพ์ขึ้นรูป 4 แม่พิมพ์ ซึ่งขึ้นรูปถาดเปียกพร้อมกัน ทำให้ได้ถาดไข่ 16 ชิ้นต่อรอบ

ข้อมูลทางเทคนิค

| Parameter | ข้อมูลจำเพาะ |

|---|---|

| ผลผลิตต่อชั่วโมง | 3,000 ชิ้น |

| พลังงาน | 60 kW |

| แหล่งจ่ายไฟ | 380V 50Hz |

| น้ำหนัก | 4,800 กก. |

| ขนาดเครื่อง (L×W×H) | 3,250×1,800×1,800 มม |

| การใช้กระดาษต่อชั่วโมง | 240 kg |

| การใช้น้ำต่อชั่วโมง | 480 กก. |

| วิธีการอบแห้ง | เตาอิฐหรือหลายชั้น |

ความแตกต่างหลักระหว่างสองเครื่อง

| Parameter | SL-3*4 | SL-4*4 | ความแตกต่าง/หมายเหตุ |

|---|---|---|---|

| ผลผลิตต่อชั่วโมง | 2,500 ชิ้น | 3,000 ชิ้น | SL-4*4 มีผลผลิตสูงขึ้น ประมาณ 500 ชิ้น/ชั่วโมงมากขึ้น |

| พลังงาน | 55 kW | 60 kW | SL-4*4 ใช้พลังงานไฟฟ้าเล็กน้อยมากขึ้น เพื่อให้ได้ผลผลิตสูงขึ้น |

| แหล่งจ่ายไฟ | 380V 50Hz | 380V 50Hz | เหมือนกัน |

| น้ำหนัก | 4,000 กก. | 4,800 กก. | SL-4*4 มีน้ำหนักมากกว่า เสถียรขึ้น |

| ขนาดเครื่อง (L×W×H) | ขนาด 2,900×1,800×1,800 มม | 3,250×1,800×1,800 มม | SL-4*4 ยาวกว่า พื้นที่เล็กลงเล็กน้อย |

| การใช้กระดาษต่อชั่วโมง | 200 กก. | 240 kg | เครื่อง SL-4*4 ใช้พลังงาน ใช้กระดาษมากขึ้น ตรงกับผลผลิตที่สูงขึ้น |

| การใช้น้ำต่อชั่วโมง | 400 กก. | 480 กก. | เครื่อง SL-4*4 ใช้พลังงาน ใช้น้ำมากขึ้น |

| วิธีการอบแห้ง | เตาอิฐหรือหลายชั้น | เตาอิฐหรือหลายชั้น | เหมือนกัน |

ข้อดีของเครื่องผลิตถาดไข่ 2,000–3,000 ชิ้น/ชั่วโมง

การตั้งค่าความจุระดับกลางถึงสูงที่เสถียร

- SL-3*4: 2,500 ชิ้น/ชั่วโมง

- SL-4*4: 3,000 ชิ้น/ชั่วโมง

ครอบคลุมความต้องการความจุหลักสำหรับโรงงานถาดไข่ขนาดกลางถึงขนาดใหญ่

ประสิทธิภาพการผลิตต่อหน่วยที่ดีขึ้น

- SL-3*4: 55 kW

- SL-4*4: 60 kW

ด้วยการเพิ่มผลผลิตประมาณ 20% กำลังไฟฟ้าจะเพิ่มขึ้นเพียง 5 kW เพื่อควบคุมการใช้พลังงานให้อยู่ในระดับที่เหมาะสม

โครงสร้างเครื่องที่แข็งแรงขึ้นเพื่อการทำงานที่เสถียรขึ้น

- น้ำหนักรวม: 4,000 กก. (SL-3*4) และ 4,800 กก. (SL-4*4)

ลดการสั่นสะเทือนที่ความเร็วสูง เพื่อให้การขึ้นรูปถาดไข่เป็นไปอย่างต่อเนื่อง

โครงเหล็กความแข็งแรงสูง

- เครื่องหลักเชื่อมด้วยเหล็กกล้าความแข็งแรงสูง ทนต่อความเมื่อยล้าและการกัดกร่อน เหมาะสำหรับการผลิตต่อเนื่องในระยะยาว

โครงสร้างกะทัดรัดใช้พื้นที่สูง

- ขนาด: 2,900×1,800×1,800 มม. (SL-3*4) และ 3,250×1,800×1,800 มม. (SL-4*4)

เพิ่มความจุสูงสุดโดยใช้พื้นที่พื้นน้อยที่สุด

การใช้วัตถุดิบตรงกับผลผลิตในเชิงเส้น

- SL-3*4: กระดาษ 200 กก./ชั่วโมง, น้ำ 400 กก./ชั่วโมง

- SL-4*4: กระดาษ 240 กก./ชั่วโมง, น้ำ 480 กก./ชั่วโมง

ช่วยให้สามารถคำนวณต้นทุนได้อย่างชัดเจนและควบคุมได้

เครื่องขึ้นรูปถาดไข่แบบหมุนหลายด้านประสิทธิภาพสูง

- การขึ้นรูปต่อเนื่อง, การบีบน้ำออก, และการถ่ายโอน

- ปรับปรุงประสิทธิภาพการผลิตและลดแรงงานด้วยมือ

ตัวเลือกการอบแห้งที่ยืดหยุ่น

- ถาดไข่ที่ขึ้นรูปแล้วสามารถจับคู่กับเตาอิฐหรือระบบอบแห้งหลายชั้น

- สามารถปรับได้ตามสภาพพลังงานในพื้นที่และงบประมาณลงทุน

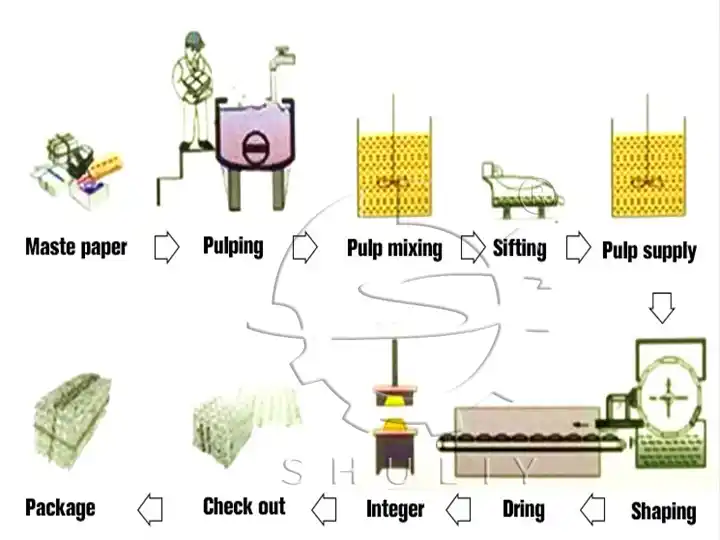

สายการผลิตถาดไข่ขนาดกลาง

สายการผลิตถาดไข่ขนาดกลาง ประกอบด้วยส่วนหลักดังนี้:

การย่อยเยื่อ

- ประกอบด้วย เครื่อง pulper, ปั๊ม pulp, และเครื่องกวน

- เศษกระดาษและน้ำผสมในอัตราส่วน 1:10 ในเครื่อง pulper เพื่อทำ pulp

- pulp เข้าสู่ถังเตรียมวัตถุดิบ ซึ่งจะเติมสารเติมแต่ง เช่น สารสีและกาวกันน้ำ แล้วผสมให้เข้ากันอย่างเต็มที่

- หลังจากเตรียม pulp แล้ว จะถูกสูบเข้าไปในถังเก็บ ซึ่งจะเติมน้ำสะอาดผ่านวาล์วเพื่อรักษาความเข้มข้นของ pulp ในถังให้อยู่ที่ 3%–5%

การขึ้นรูป

- ประกอบด้วย เครื่องขึ้นรูป, ปั๊มสุญญากาศ, และเครื่องอัดอากาศ

- แรงดันลบจากปั๊มสุญญากาศดูด pulp ไปยังแม่พิมพ์ขึ้นรูป ส่วนเกินของน้ำจะผ่านตาข่ายสแตนเลสเข้าสู่ทางออกของปั๊มสุญญากาศและกลับสู่ถังน้ำเพื่อการรีไซเคิล

- หลังจากขึ้นรูปเบื้องต้นในระหว่างการบีบน้ำด้วยสุญญากาศแล้ว เครื่องอัดอากาศจะให้แรงดันบวกเพื่อถ่ายโอนถาดไข่ที่ขึ้นรูปจากแม่พิมพ์ขึ้นรูปไปยังแม่พิมพ์ถ่ายโอน แล้วไปยังถาดหรือสายพานลำเลียง กระบวนการขึ้นรูปและถ่ายโอนเสร็จสมบูรณ์

การอบแห้ง

- ประกอบด้วย เครื่องอบแห้งด้วยสายพานตาข่ายโลหะและเตาเผา, ห้องอบแห้ง หรือเตาเผาอิฐ สามารถใช้งานได้เช่นกัน

- ถาดไข่ที่ขึ้นรูปแล้วจะถูกลำเลียงเข้าสู่เครื่องอบแห้งผ่านสายพานหรือถาด

- การอบแห้งที่อุณหภูมิ 180–220 °C เป็นเวลา 15–20 นาที เพื่อให้แน่ใจว่าถาดแห้งสนิท

การจัดเรียงและบรรจุภัณฑ์

- หลังจากการอบแห้ง ถาดจะเข้าสู่เครื่องนับอัตโนมัติและจัดเรียงอย่างเป็นระเบียบ

- สุดท้าย ถาดจะถูกบรรจุด้วยเครื่องบรรจุถาดไข่

- ถ้าต้องการถาดที่เรียบและราบเรียบมากขึ้น สามารถใช้เครื่องถาดไข่แบบกดร้อนหลังจากการอบแห้งได้

ทำไมต้องเลือกชูลี่?

Shuliy ให้บริการครบวงจร รวมถึง:

- การออกแบบโซลูชัน

- การฝึกอบรมการดำเนินงาน

- สนับสนุนด้านเทคนิคและอะไหล่ในระหว่างการผลิต

- การติดตั้งและทดสอบทั้งในสถานที่หรือระยะไกล

- การบำรุงรักษาหลังการขาย

- การปรับแต่งแม่พิมพ์และอัปเกรดผลิตภัณฑ์

- รับประกัน 1 ปี

รับรองมาตรฐานโรงงานครบถ้วน:

- CE

- ISO9001

- SGS

- TUV

- BV

- NGV

กล่องส่งมอบ

ในเดือนสิงหาคม 2025 Shuliy ช่วยลูกค้าใน Sierra Leone ติดตั้งและทดสอบเครื่องผลิตถาดไข่ 2,500 ชิ้น/ชั่วโมง ลูกค้ากำลังดำเนินการอย่างราบรื่นในสายการผลิตปกติ

โครงการนี้ช่วยให้ลูกค้าได้กำไรจากการใช้ซ้ำกระดาษรีดจำนวนมาก นอกจากนี้ยังแสดงให้เห็นถึงโซลูชันแบบครบวงจรและบริการหลังการขายที่เชื่อถือได้ของ Shuliy ซึ่งช่วยให้ลูกค้าสามารถเปลี่ยนทรัพยากรที่สูญเปล่าเป็นกำไร