Máquina de fazer bandejas de vinho de polpa | Máquina de fazer bandejas de embalagem de vinho

| Marca | Máquinas Shuliy |

| Modelo | Série SL |

| Capacidade | 1000-7000pcs/h |

| Potência | 38-120kw |

| Tensão | 380V,50HZ |

| Tamanho | Tabela de Parâmetros Técnicos de Referência |

| Garantia | 12 meses |

Agora você pode perguntar aos nossos gerentes de projeto sobre detalhes técnicos

Uma máquina de fabricação de bandejas de vinho de polpa é um equipamento industrial projetado para produzir bandejas de vinho moldadas em polpa. Ela utiliza processos como moldagem a vácuo, prensagem e secagem para dar forma à polpa em vários designs de bandejas.

As bandejas de vinho de polpa são materiais de embalagem ecológicos feitos de papel reciclado, caixas e materiais semelhantes, utilizando tecnologia de moldagem de polpa. Em comparação com embalagens de espuma tradicionais, as bandejas de vinho de polpa são mais ecológicas, biodegradáveis e oferecem um bom acolchoamento, tornando-as uma opção melhor para as necessidades modernas de embalagem sustentável.

Esta máquina para fabricar bandejas de embalagem de vinho desempenha um papel importante nas linhas de produção de embalagens verdes modernas, sendo especialmente adequada para fabricar bandejas para garrafas de vidro como vinho, champanhe e licor.

A Shuliy oferece 7 modelos de máquinas de moldagem de polpa com capacidade de 1.000 a 7.000 unidades/h, exportando mais de 50 unidades por ano.

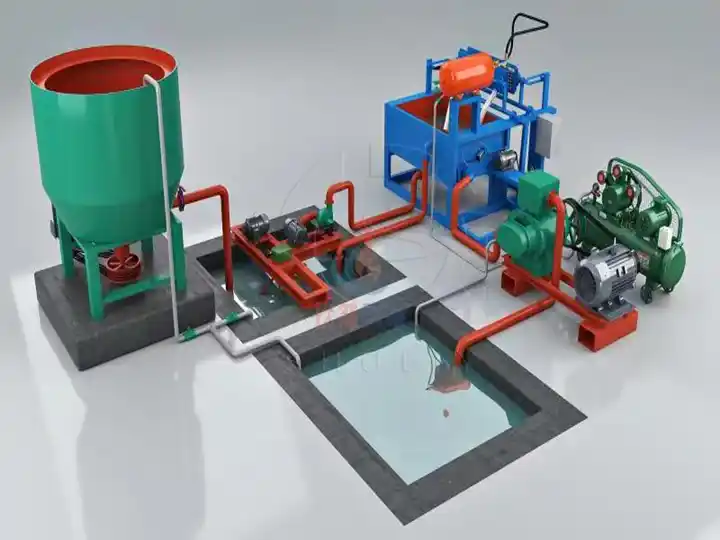

Estrutura principal da máquina de fabricação de bandejas de vinho de polpa

A máquina de fabricação de bandejas de vinho de polpa inclui principalmente o sistema de polpação, sistema de formação, sistema de secagem e sistema de embalagem.

- Sistema de desintegração: Isso inclui um desintegrador, tanque de água e misturador. Ele mistura papel reciclado com água para fazer polpa lisa. Está conectado a um dispositivo de controle de concentração de polpa.

- Sistema de formação: Isso utiliza moldes de sucção para moldar a polpa sob pressão negativa. O molde consiste em partes superior e inferior, que podem ser rapidamente trocadas para se adequar a diferentes bandejas de garrafas de vinho. O acionamento da formação pode ser hidráulico ou pneumático.

- Sistema de Secagem: Após a formação, as bandejas úmidas são secas em altas temperaturas. Existem seis métodos de secagem para escolher: secagem natural, forno de secagem, sala de secagem construída em tijolos ou secagem em metal de múltiplas camadas. Isso garante que as bandejas sejam estáveis em tamanho e lisas na superfície.

- Sistema de Embalagem: As bandejas podem ser contadas e empilhadas usando um empilhador, e depois embaladas para entrega.

Parâmetros técnicos da máquina de fabricação de bandejas de vinho de polpa Shuliy

| Modelo | Capacidade | Potência | Tensão | Peso | Uso de polpa | Uso de água | Tamanho (mm) |

| SL-1000-3X1 | 1000pcs/h | 38kw | 380V,50HZ | 2500kg | 80kg/h | 160kg/h | 2600*2200*1900 |

| SL-1500-4X1 | 1500pcs/h | 38kw | 380V,50HZ | 3000kg | 120kg/h | 240kg/h | 2800*2200*1900 |

| SL-2500-3X4 | 2500pcs/h | 55kw | 380V,50HZ | 4000kg | 200kg/h | 400kg/h | 2900*1800*1800 |

| SL-3000-4X4 | 3000pcs/h | 60kw | 380V,50HZ | 4800kg | 240kg/h | 480kg/h | 3250*1800*1800 |

| SL-4000-4X8 | 4000pcs/h | 95kw | 380V,50HZ | 7000kg | 320kg/h | 640kg/h | 3250*2300*2500 |

| SL-5000-5X8 | 5000pcs/h | 95kw | 380V,50HZ | 8000kg | 400kg/h | 800kg/h | 3700*2300*2500 |

| SL-7000-6X8 | 7000pcs/h | 120kw | 380V,50HZ | 10000kg | 480kg/h | 960kg/h | 3200*2300*2500 |

O acima é nosso modelo padrão para referência. Se você tiver requisitos mais específicos, também podemos personalizar a máquina de acordo com suas necessidades.

Como funciona a máquina de moldagem de bandejas de papel para vinho?

Semelhante à máquina de fabricação de bandejas de ovos, a máquina de formação de bandejas de vinho de polpa adota a tecnologia de formação de polpa. Segue um processo de formação de polpa onde a polpa é injetada em um molde. Em seguida, a bandeja é formada por sucção a vácuo, seca com calor e moldada em uma bandeja de resistência e design especiais.

Os principais passos de trabalho também são: polpa → formação → secagem → embalagem.

Vantagens da máquina de fabricação de bandejas de embalagem de vinho Shuliy

- Alta automaçãoDo desdobramento à formação, corte e embalagem, o processo é automático, economizando custos com mão de obra.

- Produção ecológicaSem efluentes ou emissões de gás. As matérias-primas podem ser recicladas novamente, atendendo às políticas ambientais locais.

- Moldes personalizados: Adequado para diferentes tamanhos e tipos de garrafas (como Bordeaux, Champagne, garrafas de licor). Também podemos personalizar moldes com base nas garrafas que você nos enviar.

- Acabamento de superfície agradável: As bandejas parecem suaves e limpas, perfeitas para caixas de presente de vinho premium ou exibição em showroom. Você pode personalizar a cor, a gravação do logotipo ou padrões para aprimorar sua embalagem.

- Múltiplas opções de bandejas: Pode produzir bandejas para 1, 2, 6 ou 12 garrafas.

- Desempenho estável: Controla precisamente a pressão de formação, o tempo e o ajuste do molde para garantir qualidade consistente. Comparado a máquinas comuns, pode operar 2,5 vezes mais.

- Sistema de moldes de alta precisãoTorna as bandejas mais fortes e estáveis, com bom suporte de peso e sem bordas deformadas. A bandeja possui pontos de suporte simétricos para melhor desempenho.

- Serviços personalizados disponíveis: Oferecemos design baseado em amostras, correspondência de tamanhos de garrafas, estampagem de logotipos, personalização de cores e muito mais para ajudar sua marca a se destacar. Soluções de embalagem completas podem ser fornecidas com a máquina de formação de bandejas.

- Linha de produção completa e solução disponível: Como fabricante direto, podemos fornecer máquinas de polpa, compressores de ar, secadores e outros equipamentos. Também oferecemos um planejamento razoável do layout do terreno para ajudar a reduzir seus custos com mão de obra.

Quais são os tipos de bandejas de papel para vinho?

| Categoria | Tipo |

| Por Volume da Garrafa | 187ml, 375ml, 500ml, 700ml, 750ml, 1L, 1.5L, 3L / 5L |

| Por Quantidade de Garrafas | Uma garrafa, Duas garrafas, Quatro garrafas, Seis garrafas, Doze garrafas |

| Por Estrutura | Tipo de peça única, Tipo separado em cima e embaixo, Tipo inserido |

| Por Processo de Moldagem | Moldagem por prensagem a seco, Moldagem por prensagem a úmido |

| Por Uso | Tipo de proteção para transporte, Tipo de exibição em caixa de presente, Tipo de exportação |

Por que escolher uma máquina de fabricação de bandejas para embalagem de vinho?

Tem amplas aplicações:

- Fabricantes de vinho: Usado para embalagem interna de produtos de vinho engarrafados.

- Plataformas de e-commerce: Ideal para o envio seguro de uma ou várias garrafas de vinho.

- Empresas de embalagem para presentesUsado para bandejas dentro de caixas de vinho de presente ou conjuntos de vinho premium.

- Comerciantes de exportação: Atende às regulamentações de ecoembalagem na UE, EUA e outros países.

- Supermercados e lojas de varejo: Usado para pacotes combinados, tornando a exibição e as vendas mais convenientes.

Vantagens em comparação com outros materiais de embalagem:

| Item | Bandeja de vinho de papelão | Bandeja de espuma plástica | Inserto de Papel Ondulado |

| Ambiental | Biodegradável, ecológico | Não biodegradável | Reciclável |

| Proteção | Forte | Muito forte | Médio |

| Custo | Médio | Mais alto | Mais baixo |

| Personalização | Alto | Médio | Médio |

| Aparência | Bom (melhor com prensagem a úmido) | Pobre | Médio |

Produtos acabados da máquina de fabricação de bandejas de vinho de polpa

As bandejas de vinho de polpa que frequentemente produzimos estão mostradas abaixo. No entanto, temos muitas outras opções de moldes disponíveis. Se você estiver interessado, sinta-se à vontade para nos contatar a qualquer momento!

Exibição de envio da máquina de fabricação de bandejas de papel para vinho

Aqui estão algumas das nossas fotos de envio. Você pode dar uma olhada na nossa embalagem.