जूते की ट्रे बनाने की मशीन

| ब्रांड | शुली मशीनरी |

| मॉडल | SL श्रृंखला |

| क्षमता | 1000-7000पीसीएस/घंटा |

| शक्ति | 38-120किलोवाट |

| वोल्टेज | 380V,50HZ |

| आकार | संदर्भ तकनीकी पैरामीटर तालिका |

| वारंटी | 12 महीने |

आप अब हमारे परियोजना प्रबंधकों से तकनीकी विवरण पूछ सकते हैं

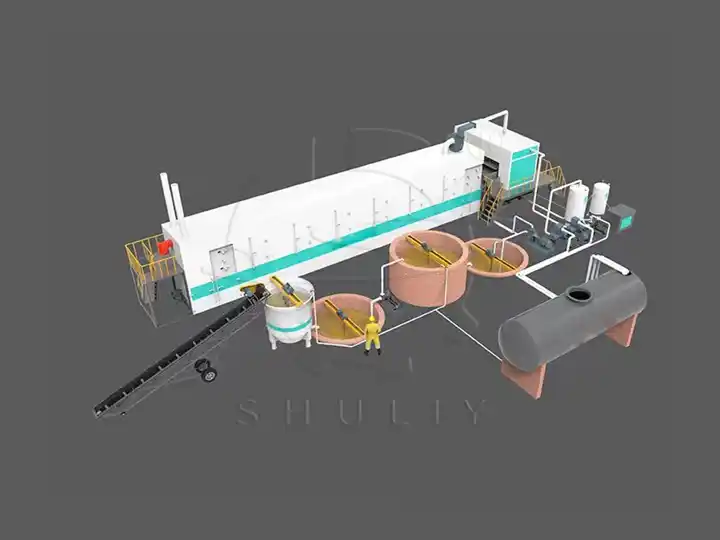

जूता ट्रे बनाने की मशीन एक विशेष उपकरण है जिसका उपयोग मोल्डेड पल्प जूता ट्रे बनाने के लिए किया जाता है। यह कच्चे माल के रूप में अपशिष्ट कागज के गूदे का उपयोग करता है और जूते के लिए पल्प पैकेजिंग, जिसमें जूता इंसर्ट, जूता सपोर्ट और बॉटम ट्रे शामिल हैं, का बड़े पैमाने पर उत्पादन करने के लिए गूदा मोल्डिंग, बनाने, डीमोल्डिंग और सुखाने की प्रक्रियाओं को पूरा करता है।

जूता ट्रे का व्यापक रूप से स्नीकर्स, चमड़े के जूते, कैज़ुअल जूते और बच्चों के जूते की पैकेजिंग में उपयोग किया जाता है। वे प्लास्टिक और फोम पैकेजिंग के लिए एक पर्यावरण-अनुकूल, बायोडिग्रेडेबल विकल्प प्रदान करते हैं।

हमारी पूरी तरह से स्वचालित जूता ट्रे बनाने वाली मशीन की उत्पादन क्षमता 1,000 से 7,000 पीस प्रति घंटा है। हम आपकी विशिष्ट आकार और आकृति की आवश्यकताओं को पूरा करने के लिए अनुकूलित मोल्ड डिजाइन भी प्रदान करते हैं।

जूता ट्रे बनाने की मशीन का कार्य सिद्धांत

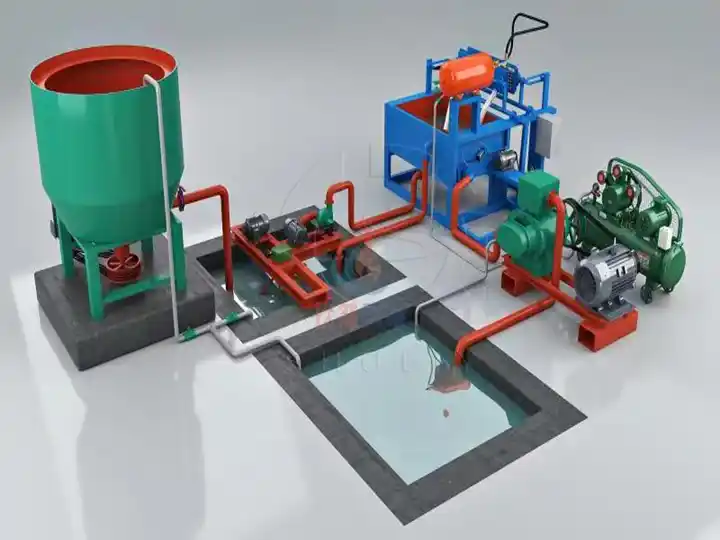

यह मशीन वैक्यूम फॉर्मिंग तकनीक का उपयोग करती है:

पल्पिंग सिस्टम

बर्बाद कागज को समान पल्प में संसाधित किया जाता है।

फार्मिंग सिस्टम

- मोल्ड को पल्प टैंक में डुबोया जाता है।

- वैक्यूम पंप पल्प को मोल्ड की सतह पर खींचता है।

- मोल्ड अतिरिक्त पानी निकालने के लिए उठता है।

डेमोल्डिंग

संकुचित हवा या यांत्रिक बल गीली ट्रे को बाहर निकालता है।

सूखना

ट्रे को सुखाने वाली ओवन या सुखाने के कमरे का उपयोग करके सुखाया जाता है।

ट्रिमिंग और आकार देना

अंतिम आकार देना, किनारा काटना, और पैकेजिंग।

मुख्य कार्यात्मक चरण

पल्पिंग → बनाना → सुखाना → पैकेजिंग।

मशीन के घटक

- पल्प टैंक – पल्प को समान रूप से संग्रहीत और मिलाता है

- मुख्य निर्माण मशीन - कोर निर्माण इकाई जिसमें मोल्ड सीटें हैं।

- वैक्यूम पंप – पल्प को मोल्ड पर खींचता है

- एयर कंप्रेसर सिस्टम – उत्पाद निष्कासन में मदद करता है

- मोल्ड सिस्टम - कस्टम मोल्ड ट्रे के आकार को परिभाषित करते हैं

- सूखने का उपकरण - इलेक्ट्रिक या गर्म हवा से सूखना

- नियंत्रण पैनल - वैक्यूम, समय और तापमान सेट करने के लिए पीएलसी प्रणाली।

बिक्री के लिए गर्म बिक्री वाले जूते की ट्रे बनाने वाली मशीनें

| मॉडल | क्षमता | शक्ति | वोल्टेज | वजन | पल्प उपयोग | पानी उपयोग | आकार (मिमी) |

| SL-1000-3X1 | 1000पीसी/घंटा | 38किलोवाट | 380V,50HZ | 2500किलो | 80किग्रा/घंटा | 160किग्रा/घंटा | 2600*2200*1900 |

| SL-1500-4X1 | 1500पीस/घंटा | 38किलोवाट | 380V,50HZ | 3000किग्रा | 120किग्रा/घंटा | 240किग्रा/घंटा | 2800*2200*1900 |

| SL-2500-3X4 | 2500पीस/घंटा | 55किलोवाट | 380V,50HZ | 4000किग्रा | 200किग्रा/घंटा | 400किग्रा/घंटा | 2900*1800*1800 |

| SL-3000-4X4 | 3000पीसी/घंटा | 60किलोवाट | 380V,50HZ | 4800किग्रा | 240किग्रा/घंटा | 480किग्रा/घंटा | 3250*1800*1800 |

| SL-4000-4X8 | 4000पीस/घंटा | 95किलोवाट | 380V,50HZ | 7000किलोग्राम | 320किग्रा/घंटा | 640किग्रा/घंटा | 3250*2300*2500 |

| SL-5000-5X8 | 5000पीसी/घंटा | 95किलोवाट | 380V,50HZ | 8000किग्रा | 400किग्रा/घंटा | 800किग्रा/घंटा | 3700*2300*2500 |

| SL-7000-6X8 | 7000पीस/घंटा | 120क्वाट | 380V,50HZ | 10000 किलोग्राम | 480किग्रा/घंटा | 960 किलोग्राम/घंटा | 3200*2300*2500 |

हम आपकी आवश्यकताओं के अनुसार मशीन में विशेषताएँ जोड़ने या हटाने के द्वारा अनुकूलित कर सकते हैं। अधिक जानकारी के लिए हमसे संपर्क करने में संकोच न करें।

शुली जूते की ट्रे बनाने वाली मशीनें क्यों चुनें?

पर्यावरण के अनुकूल और बायोडिग्रेडेबल

- पुनर्नवीनीकरण कागज (समाचार पत्र, गत्ते का डिब्बा, किताबें) से बना।

- 100% जैव-निष्क्रिय, वैश्विक "प्लास्टिक कमी" लक्ष्यों के अनुरूप

- निर्यात के लिए आदर्श ईयू, अमेरिका, और अन्य पर्यावरण-प्रवृत्त बाजार

उच्च अनुकूलन योग्य

- विभिन्न जूते के आकार और प्रकार के लिए अनुकूलित मोल्ड

- एकल या डबल जूते के ट्रे, इनसोल, इन्सर्ट आदि का उत्पादन कर सकता है।

- लोगोब्रांडिंग के लिए मोल्ड पर टेक्सचर्ड पैटर्न उकेरे जा सकते हैं।

लागत-बचत और स्थान-कुशल

- कम कच्चे माल की लागत

- स्टैक करने योग्य, संकुचन योग्य संरचना परिवहन स्थान बचाती है।

- उच्च टिकाऊपन शिपिंग के दौरान उत्पाद क्षति को कम करता है।

लचीले आउटपुट विकल्प

- क्षमता रेंज 1000 से 7000 पीसी/घंटा

- सेमी-ऑटोमैटिक एकल-स्टेशन से उपलब्ध है पूर्ण स्वचालित मल्टी-स्टेशन लाइनों

- जूते के निर्माताओं, ई-कॉमर्स, या पैकेजिंग सेवा प्रदाताओं के लिए उपयुक्त।

स्थिर प्रदर्शन और आसान संचालन

- PLC टचस्क्रीन नियंत्रणl, अंतर्ज्ञानात्मक और कुशल

- बहु-उत्पाद स्विचिंग के लिए त्वरित मोल्ड परिवर्तन प्रणाली।

- स्टेनलेस स्टील या कोटेड कार्बन स्टील से बना टिकाऊ फ्रेम।

बहुउद्देशीय उपयोग

- मोल्ड बदलकर, एक ही मशीन निम्नलिखित का उत्पादन भी कर सकती है: वाइन ट्रेकॉस्मेटिक पैकेजिंग/इलेक्ट्रॉनिक्स इंसर्ट/छोटे उपकरणों के ट्रे

अपने ब्रांड की छवि को बढ़ाएं

- शानदार और टिकाऊ पैकेजिंग उत्पाद की अपील को बढ़ाती है।

- कस्टम-उभरे हुए ट्रे ब्रांड पहचान को दर्शाते हैं

- निर्यात के लिए पर्यावरण के अनुकूल, खरीदारों का विश्वास बढ़ाना

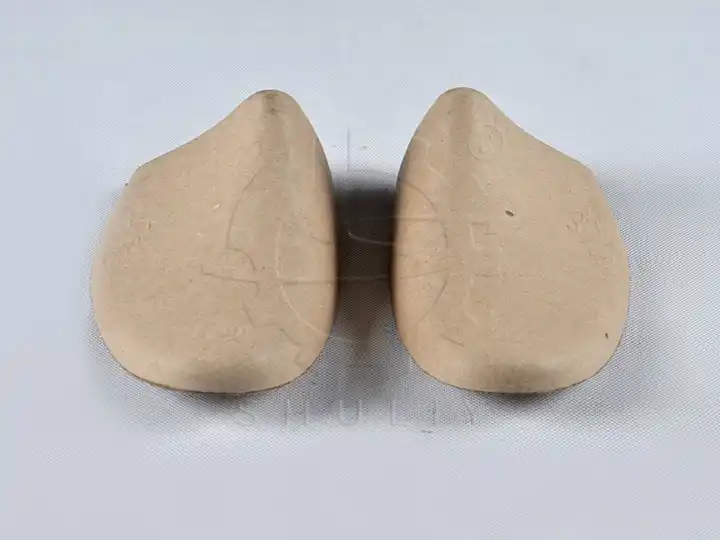

सामान्य जूते की ट्रे के प्रकार

- जूते के इनसर्ट - जूते का आकार बनाए रखने के लिए

- तल के ट्रे - जूते के जोड़ों को पैक करने के लिए

- बॉक्स इनसर्ट - अंदर के जूते के बॉक्स की सुरक्षा के लिए

- लोगो-स्टैम्प किए गए ट्रे - अनुकूलित ब्रांडिंग

मोल्ड डिज़ाइन टिप्स

- सुगम पल्प सक्शन के लिए अच्छा वेंटिलेशन लेआउट

- कम trimming के लिए चिकनी धारियाँ

- संरचना के लिए सतह उपचार (सैंडब्लास्टिंग/पॉलिशिंग)

- कुशल मोल्ड स्वैप के लिए त्वरित परिवर्तन संरचना

- उच्च-सटीकता और एंटी-कोरोशन उपचार जीवनकाल बढ़ाता है

जूते की ट्रे बनाने की मशीन का उपयोग कब करें

पर्यावरण के अनुकूल जूते के पैकेजिंग का बड़े पैमाने पर उत्पादन

जब आपको स्नीकर्स, चमड़े के जूतों या बच्चों के जूतों के लिए बायोडिग्रेडेबल जूते की ट्रे की बड़ी मात्रा में उत्पादन करने की आवश्यकता होती है।

प्लास्टिक या फोम पैकेजिंग का प्रतिस्थापन

यदि आपका ब्रांड या ग्राहक पर्यावरणीय नियमों को पूरा करने के लिए स्थायी पैकेजिंग समाधानों की ओर बढ़ रहे हैं।

निर्यात जूता पैकेजिंग आवश्यकताएँ

जब आप उन क्षेत्रों में निर्यात कर रहे हैं जहाँ कड़े पर्यावरणीय नीतियाँ हैं (जैसे, यूरोप, उत्तरी अमेरिका), जहाँ पुनर्नवीनीकरण, प्लास्टिक-मुक्त पैकेजिंग की आवश्यकता होती है।

कस्टमाइज्ड जूता समर्थन समाधान

जब आपको कस्टम-मोल्डेड ट्रे की आवश्यकता होती है जैसे जूते के इंसर्ट, नीचे की ट्रे, या लोगो या पैटर्न के साथ ब्रांडेड पैकेजिंग।

पैकेजिंग लागत कम करना

जब फोम या प्लास्टिक के लिए एक लागत-कुशल विकल्प की तलाश कर रहे हैं, जिसमें कच्चे माल और परिवहन की लागत कम हो।

इन-हाउस पैकेजिंग उत्पादन स्थापित करना

जूते की फैक्ट्रियों या पैकेजिंग कंपनियों के लिए जो गुणवत्ता को नियंत्रित करना चाहते हैं और साइट पर ट्रे बनाकर आउटसोर्सिंग को कम करना चाहते हैं।