पेपर अंडे की ट्रे कैसे बनाएं? 8-तरफा अंडे की ट्रे बनाने की मशीन आपको चरण-दर-चरण दिखाती है।

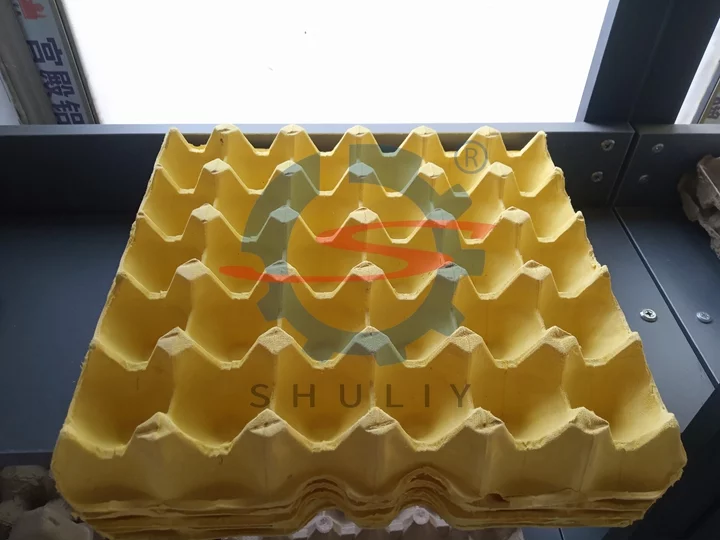

कागज़ के अंडे की ट्रे, रिसाइकल वेस्ट पेपर से बनी, अंडे, फलों और सब्ज़ियों के पैकेजिंग के लिए आदर्श हैं क्योंकि इनमें कुशन और सांस लेने की क्षमता है। जैसे-जैसे ई-कॉमर्स और ताजा उत्पाद बाज़ार बढ़ते हैं, पेपर ट्रे की मांग भी बढ़ रही है। इस मांग को पूरा करने के लिए 8-आयामी अंडा ट्रे बनाने की मशीन निर्माण लाइनों को अपग्रेड करने के लिए निर्माता द्वारा चयनित विकल्प बन गया है।

पारंपरिक 1- या 4-पक्षीय मशीनों की तुलना में, यह अधिक फॉर्मिंग स्टेशनों, उच्च उत्पादन और कम डाउनटाइम की पेशकश करता है। 8-पक्षीय डिज़ाइन त्वरित मोल्ड परिवर्तनों और विभिन्न उत्पादों के लिए अनुकूलन की अनुमति भी देता है, जिससे व्यवसायों को लागत कम करने और प्रतिस्पर्धी बने रहने में मदद मिलती है।

तो, 8-कोणीय मशीन अंडे की ट्रे कैसे बनाती है? आइए इसे करीब से देखें।

पेपर अंडे ट्रे के लिए कच्चे माल और संग्रह

पेपर अंडे ट्रे के लिए मुख्य कच्चा माल बर्बाद पेपर है - जैसे पुराने समाचार पत्र, कार्टन और कार्डबोर्ड। इन सामग्रियों को पुनर्नवीनीकरण और पुन: उपयोग किया जाता है, जिससे अंडे की ट्रे एक पारिस्थितिकी अनुकूल पैकेजिंग समाधान बन जाती है।

कच्चे माल के प्रकार

- पुराने समाचार पत्र

लंबे फाइबर अच्छी ताकत और लचीलापन प्रदान करते हैं। समाचार पत्र के गूदे से बने अंडे के ट्रे मजबूत होते हैं और दरारों के प्रति प्रतिरोधी होते हैं - अंडों जैसे नाजुक वस्तुओं की सुरक्षा के लिए आदर्श।

- कार्टन और कार्डबोर्ड

छोटी फाइबर, लेकिन कम लागत और बड़े पैमाने पर उत्पादन के लिए उपयुक्त। पल्पिंग के बाद, वे अच्छी संरचनात्मक ताकत प्रदान करते हैं, जो मोटे या सुदृढ़ ट्रे के लिए बिल्कुल सही हैं।

- मिक्स्ड वेस्ट पेपर

विभिन्न कागज प्रकारों का मिश्रण, लचीले अनुपातों के साथ, विभिन्न ताकत और मोटाई की आवश्यकताओं को पूरा करने के लिए अनुकूलित।

- विशेष पेपर कचरा (वैकल्पिक जोड़)

सतह की चिकनाई या दबाव प्रतिरोध को बेहतर बनाने के लिए ग्राहकों की आवश्यकताओं के आधार पर क्राफ्ट पेपर या सफेद कार्डबोर्ड जैसे सामग्री जोड़ी जा सकती हैं।

कैसे वेस्ट पेपर इकट्ठा किया जाता है

- रीसाइक्लिंग कंपनियाँ

कचरे के पेपर के बड़े मात्रा में संग्रह करने वाले प्रमुख सप्लायर्स, जैसे पुराने अखबार (ONP), पुराने मासिक पत्रिकाएँ (OMG), मिश्रित दफ्तर कचरा (MOW), और बक्से व कंटेनर जैसे पैकेजिंग सामग्री।

- व्यक्तिगत स्रोत

घरों या कार्यालयों से कागज़ का कचरा, जो आमतौर पर मात्रा में छोटा होता है और पुनर्चक्रण स्टेशनों को बेचा जाता है। ये सामग्री अधिक विविध होती हैं और अक्सर निम्न गुणवत्ता की होती हैं।

- कागज कारखाने

कागज़ मिलों, पैकेजिंग संयंत्रों और प्रिंटिंग हाउस से बचे हुए टुकड़े और कटाव। इस प्रकार का कचरा आमतौर पर अधिक साफ और स्थिर होता है - उत्पादन में पुन: उपयोग के लिए आदर्श।

8-कोणीय अंडे की ट्रे बनाने की मशीन की उत्पादन प्रक्रिया

8-पक्षीय अंडे की ट्रे बनाने की मशीन एक पूरी तरह से स्वचालित पल्प मोल्डिंग प्रणाली है, जिसका व्यापक रूप से अंडों, फलों, सब्जियों और औद्योगिक पैकेजिंग के लिए पर्यावरण के अनुकूल ट्रे बनाने के लिए उपयोग किया जाता है। इसका उत्पादन प्रक्रिया चार मुख्य प्रणालियों में विभाजित है।

पल्पिंग सिस्टम

- कच्चे माल की आपूर्ति: कचरा कागज, पुराने समाचार पत्र, और कार्टन को हाइड्रोलिक पल्पर में डाला जाता है।

- पल्प तैयारी: सामग्री को पानी के संचार के तहत पल्प फाइबर में काटा जाता है। पल्प की स्थिरता उत्पाद के अनुसार भिन्न होती है।

- पल्प मिश्रण और समायोजन: पल्प को पतला किया जाता है, छाना जाता है, और मिश्रण टैंकों में समरूप किया जाता है ताकि निर्माण आवश्यकताओं को पूरा किया जा सके।

फॉर्मिंग सिस्टम

- वैक्यूम फॉर्मिंग: गुदा को फॉर्मिंग मोल्ड्स में पंप किया जाता है, जो गुदा टैंक में डूबे होते हैं। वैक्यूम सक्शन के तहत, फाइबर मोल्ड सतह पर एक गीला ट्रे बनाते हैं।

- 8-तरफा घूर्णन तालिका: 8 सेट के मोल्ड्स से सुसज्जित, घूर्णन मंच निरंतर निर्माण, जल निकासी, और डेमोल्डिंग सुनिश्चित करता है।

- स्वचालित डेमोल्डिंग: संकुचित हवा गीले ट्रे को मोल्ड से हटाने के लिए उड़ती है ताकि अगली प्रक्रिया शुरू हो सके।

सूखने का सिस्टम

- सूखने के विकल्प: फैक्ट्री सेटअप के आधार पर धातु के सूखने की लाइनों, ईंट के सूखने की सुरंगों, या प्राकृतिक धूप में सूखने में से चुनें।

- स्वचालित स्टैकिंग: सूखे ट्रे को स्वचालित स्टैकर द्वारा व्यवस्थित रूप से स्टैक किया जाता है, जिससे पैकिंग की दक्षता में सुधार होता है।

- पैकिंग और डिलीवरी: ट्रे को मैन्युअल या स्वचालित रूप से पैक किया जाता है, फिर शिपमेंट के लिए बॉक्स में रखा जाता है - उत्पादन लाइन को पूरा करते हुए।

8-तरफा अंडे की ट्रे मशीन के प्रमुख लाभ

- उच्च उत्पादन: उत्पन्न करता है 4,000–7,000 प्रति घंटे ट्रे, बड़े पैमाने पर उत्पादन के लिए आदर्श।

- उच्च स्वचालन: पूर्ण स्वचालित संचालन के साथ श्रम लागत को न्यूनतम करता है।

- कस्टम मोल्ड उपलब्ध: विभिन्न ट्रे प्रकारों और आकारों के लिए एल्युमिनियम या स्टेनलेस स्टील के मोल्ड्स का समर्थन करता है।

- भारी-भरकम फ्रेमस्थायित्व के लिए मोटे कार्बन स्टील से निर्मित; मशीन का जीवनकाल अधिक है। 10 साल।

- संपूर्ण एकीकरण: पूर्ण रूप से जुड़े उत्पादन लाइन के लिए स्वचालित सुखाने और स्वचालित ढेर लगाने के सिस्टम के साथ संगत।

8-कोणीय अंडे की ट्रे बनाने की मशीन के लिए अनुशंसित मॉडल

मॉडल: SL-5000-5X8

क्षमता: 5000पीसी/घंटा

शक्ति: 95किलोवाट

वोल्टेज: 380V,50HZ

वजन: 8000किलोग्राम

पल्प उपयोग: 400किग्रा/घंटा

पानी उपयोग: 800किग्रा/घंटा

आकार (मिमी): 3700*2300*2500

उत्पादन तिथि: 25-40 कार्य दिवस

परिवहन: समुद्र द्वारा

8-कोणीय अंडे की ट्रे मशीन के पर्यावरणीय और आर्थिक लाभ

सतत और पर्यावरण के अनुकूल उत्पादन

- संसाधन पुनर्चक्रण

कच्चे माल के रूप में बर्बाद कागज, पुराने समाचार पत्र और कार्टन का उपयोग—पेड़ काटने की आवश्यकता को कम करना।

कठिनाई से निपटने वाले कचरे को मूल्यवान पैकेजिंग में बदलना, बंद लूप संसाधन पुनर्चक्रण प्राप्त करना।

- जल संरक्षण

पल्पिंग में उपयोग किया गया पानी फ़िल्टर किया जाता है और पुनः उपयोग किया जाता है, पानी की खपत को न्यूनतम करना।

पूरे सिस्टम को कम पानी के उपयोग के लिए डिज़ाइन किया गया है, ऊर्जा-बचत मानकों के अनुरूप।

- शून्य प्रदूषण

कोई हानिकारक रसायनों की आवश्यकता नहीं।

उत्पादन के दौरान कोई अपशिष्ट जल या उत्सर्जन नहीं।

पूर्ण ट्रे बायोडिग्रेडेबल और पुनर्नवीनीकरण योग्य हैं, वास्तव में हरे पैकेजिंग को सक्षम करना।

मजबूत आर्थिक लाभ

- उच्च उत्पादन, कम श्रम

24/7 चलती है, प्रति घंटे 4,000–7,000 ट्रे (मोल्ड पर निर्भर).

ऑटो ड्रायिंग और स्टैकिंग सिस्टम के साथ श्रम और निगरानी लागत को बहुत कम करती है।

- टिकाऊ और कम रखरखाव

पक्का कार्बन स्टील और प्रीमियम bearings के साथ निर्मित, 10000 वर्ष से अधिक उपयोग के साथ।

मोल्ड जल्दी बदलना, कम ब्रेकडाउन दर, लागत-मुक्त रखरखाव।

- तेज़ वापसी

छोटी और मध्यम फैक्ट्रियों के लिए आदर्श—निवेश पर त्वरित रिटर्न।

कम लागत वाली कच्ची सामग्री और उच्च लाभ मार्जिन स्थिर आय सुनिश्चित करते हैं।

- वैश्विक बाजार अनुकूलता

अंडों, उत्पादन, इलेक्ट्रॉनिक्स और दवाओं के लिए पेपर ट्रे की उच्च मांग है।

स्थायी पैकेजिंग की वैश्विक प्रवृत्ति के साथ संरेखित।