วิธีการปรับแต่งถาดไข่ควาย

ตามที่เป็นที่รู้กันดี การเติบโตของการเลี้ยงนกกระทาและความต้องการผลิตภัณฑ์ไข่ที่หลากหลายทำให้ไข่นกกระทากลายเป็นที่นิยมในบ้าน อุตสาหกรรมอาหาร และตลาดส่งออก อย่างไรก็ตาม ไข่นกกระทามีขนาดเล็ก เปราะบาง และมีเปลือกบาง วิธีการขนส่งแบบดั้งเดิมมักทำให้เกิดการแตกหัก การปนเปื้อน และของเสีย

เพื่อแก้ปัญหานี้ แผ่นรองไข่กระทายถูกพัฒนาขึ้น แผ่นรองเหล่านี้ถูกออกแบบมาเป็นพิเศษด้วยช่องที่เหมาะสมและการกันกระแทกเพื่อยึดไข่ให้แน่น ป้องกันการชนกันระหว่างการขนส่ง และลดความเสียหายอย่างมาก ผลิตจากเยื่อกระดาษ พวกมันเป็นมิตรกับสิ่งแวดล้อม ย่อยสลายได้ และสามารถปรับแต่งได้ ทำให้กลายเป็นตัวเลือกบรรจุภัณฑ์หลักอย่างรวดเร็ว.

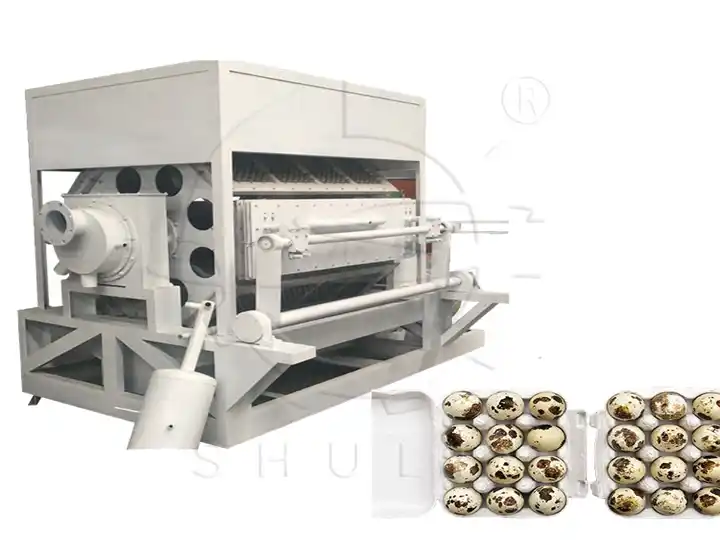

เพื่อแก้ไขปัญหานี้ เราได้พัฒนาเครื่องทำถาดไข่นกกระทาโดยเฉพาะ โดยมุ่งเน้นไปที่การออกแบบและการปรับแต่งถาดไข่นกกระทา ควบคู่ไปกับเทคโนโลยีแม่พิมพ์ขั้นสูง

การใช้งานที่หลากหลายของถาดไข่กระทา

- ฟาร์มกระทา: เหมาะสำหรับฟาร์มขนาดเล็กและขนาดใหญ่ในการคัดแยก บรรจุ และขนส่งไข่ที่เก็บได้ในแต่ละวันอย่างปลอดภัย

- ศูนย์คัดแยกไข่ / โรงงานแปรรูปไข่: การใช้ถาดไข่กระต๊ากจากกระดาษเพิ่มมูลค่าและปรับปรุงภาพลักษณ์ของแบรนด์ในขณะที่ยังคงความปลอดภัยในการจัดการ

- โรงงานบรรจุภัณฑ์เยื่อกระดาษ: ผู้ผลิตสามารถผลิตถาดไข่กระต๊ากในปริมาณมากและจัดส่งไปยังฟาร์ม ซูเปอร์มาร์เก็ต และแพลตฟอร์มอีคอมเมิร์ซ

- ตลาดการเกษตร / ตลาดขายส่ง: ปรับปรุงการแสดงผลผลิตภัณฑ์ ทำให้การจัดเรียงและการขนส่งง่ายขึ้น และรักษาไข่ให้สะอาดและปลอดภัย

- บริษัทอีคอมเมิร์ซและการจัดส่งอาหารสด: ถาดกระดาษที่รวมกับกล่องช่วยปกป้องไข่กระต๊ากระหว่างการขนส่งและลดความเสียหาย

- ซูเปอร์มาร์เก็ตและร้านค้าปลีก: สามารถใช้แสดงบนชั้นวางได้โดยตรง พวกเขาเป็นมิตรกับสิ่งแวดล้อม ดึงดูด และสะดวกสำหรับลูกค้า

- บริษัทส่งออก: ถาดเยื่อกระดาษตรงตามมาตรฐานสิ่งแวดล้อมระดับสากลและเหมาะสำหรับการบรรจุส่งออกไข่กระต๊าก

กระบวนการปรับแต่งถาดไข่กระทาแบบทั่วไป

การยืนยันความต้องการ → การออกแบบแม่พิมพ์ → การทดสอบตัวอย่าง → การอนุมัติจากลูกค้า → การปรับปรุง → การผลิตจำนวนมาก → การบรรจุและจัดส่ง

จุดสำคัญที่ควรพิจารณาเมื่อปรับแต่งถาดไข่กระต๊าก

ขนาดที่แม่นยำ

ไข่กระดาษเป็นไข่ขนาดเล็ก (2–3 ซม. เส้นผ่านศูนย์กลาง) ขนาดถาดต้องพอดีเพื่อหลีกเลี่ยงการสั่นหรือการติดขัด.

การออกแบบแม่แบบมืออาชีพ

รูปแบบรูต้องแน่นและเรียบเพื่อป้องกันความเสียหายของเปลือกไข่ ต้องการความแม่นยำสูง.

ความหนาของถาดที่สมดุล

ถาดควรมีน้ำหนักเบาแต่แข็งแรงพอสมควร ถ้าเบาเกินไปจะพัง; ถ้าแน่นเกินไปจะเพิ่มต้นทุนและเวลาการอบแห้ง.

ระบายอากาศได้และกันความชื้น

วัสดุเยื่อกระดาษควรดูดซับความชื้นและอนุญาตให้อากาศหมุนเวียนเพื่อป้องกันเชื้อราและกลิ่น.

รูปแบบหลายเซลล์

ประเภททั่วไป: 30, 60 หรือ 90 ช่อง นี่ต้องการการวางรูปแบบแม่พิมพ์อย่างระมัดระวังและการสร้างเยื่อกระดาษที่แม่นยำ.

การออกแบบฝาแท่นรวม

ลูกค้าบางรายชอบถาดที่มีฝาปิด ซึ่งต้องการการประสานงานระหว่างแม่พิมพ์และเครื่องจักรที่ซับซ้อนมากขึ้น.

ความท้าทายทั่วไปในการผลิตถาดไข่กระทา

- การออกแบบแม่พิมพ์ที่ยาก: แม่พิมพ์ถาดไข่กระดาษมีขนาดเล็กและหนาแน่น ผู้ผลิตแม่พิมพ์ทั่วไปหลายรายไม่สามารถทำการดูดซับเยื่อกระดาษได้อย่างแม่นยำ ทำให้เกิดข้อบกพร่อง.

- ความแม่นยำในการดูดซับเยื่อกระดาษต่ำ: แม่พิมพ์ขนาดเล็กต้องการการควบคุมเวลาว่างและความดันที่แม่นยำมากขึ้นเพื่อหลีกเลี่ยงถาดที่ไม่สมบูรณ์หรือไม่สม่ำเสมอ.

- ปัญหาการถอดแบบ: แม่พิมพ์ที่ลึกและหนาแน่นอาจทำให้ถาดขาดหรือเกาะติดกัน ทำให้ลดอัตราผลผลิต.

- ความท้าทายในการทำให้แห้ง: จำนวนช่องที่มากขึ้น = ถาดที่หนาแน่นขึ้น การไหลของอากาศร้อนที่ไม่สม่ำเสมออาจทำให้กลางถาดชื้นและขอบแห้งเกินไป.

- ความยากลำบากในการเพิ่มความสามารถในการผลิต: เครื่องผลิตถาดไข่มาตรฐานถูกออกแบบมาสำหรับไข่ไก่ เมื่อใช้สำหรับถาดไข่ควายที่มีความหนาแน่นสูงและมีหลายหลุม ความสามารถในการผลิตจะลดลงอย่างมาก และประสิทธิภาพจะไม่เสถียร.

- ความเข้ากันได้ที่ไม่ดีของเครื่องจักรที่รวมกัน: หลายเครื่องจักรไม่สามารถปรับเปลี่ยนด้วยแม่พิมพ์หรือระบบยึดเพื่อผลิตถาดไข่กระทาแบบมีฝา ทำให้ยากต่อการเปลี่ยนไปใช้โครงสร้างนี้

โซลูชันที่แนะนำโดย Shuliy

- แม่พิมพ์ถาดไข่กระทาที่ออกแบบเฉพาะเพื่อให้มั่นใจในขนาดที่แม่นยำและการจัดเรียงที่เหมาะสม

- ระบบควบคุมการดูดซับเยื่อกระดาษอัจฉริยะเพื่อรับประกันการดูดซับเยื่อกระดาษที่สม่ำเสมอสำหรับแต่ละช่อง

- กรอบแม่พิมพ์ที่กว้างขึ้นและการออกแบบโต๊ะหมุนหลายสถานีที่ปรับแต่งเพื่อเพิ่มประสิทธิภาพสำหรับโครงสร้างที่หนาแน่น

- ระบบสายการอบแห้งที่มีคุณภาพเพื่อให้แน่ใจว่าแห้งสม่ำเสมอและรวดเร็ว

- การออกแบบการขึ้นรูปแบบบูรณาการที่เลือกได้เพื่อตอบสนองความต้องการของตลาดบรรจุภัณฑ์ระดับสูง

ร่วมมือกับเรา

หากสนใจ กรุณาติดต่อเราเพื่อขอรายละเอียดผ่าน WhatsApp โดยตรง: https://wa.me/+8619139761487